high quality rubber slurry pump factory

Latest articles

Aier is pumping experts and offer some useful tips to maintain your >slurry pump.

high quality rubber slurry pump factory...

high quality rubber slurry pump factory 【high quality rubber slurry pump factory】

Read MoreTo find out more about Aier slurry Pumps, please >contact us.

high quality rubber slurry pump factory...

high quality rubber slurry pump factory 【high quality rubber slurry pump factory】

Read MoreMany types of pumps are used to pump slurry, but the most common slurry pump is the centrifugal pump. Centrifugal slurry pumps use centrifugal force from a rotating impeller to impinge kinetic energy on the slurry, similar to the way watery liquids pass through a standard centrifugal pump.

high quality rubber slurry pump factory...

high quality rubber slurry pump factory 【high quality rubber slurry pump factory】

Read MoreThe mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete.

high quality rubber slurry pump factory...

high quality rubber slurry pump factory 【high quality rubber slurry pump factory】

Read More- Portable and low maintenance - There are no long or exposed mechanical shafts between the motor and worm gear, which makes the submersible pump more portable. In addition, because there are no long or exposed mechanical connections between the motor and worm gear, less maintenance is required and operating costs are significantly lower.

high quality rubber slurry pump factory...

high quality rubber slurry pump factory 【high quality rubber slurry pump factory】

Read MoreLight-duty Slurry Pump

high quality rubber slurry pump factory...

high quality rubber slurry pump factory 【high quality rubber slurry pump factory】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

high quality rubber slurry pump factory...

high quality rubber slurry pump factory 【high quality rubber slurry pump factory】

Read MoreWhat are the materials used to construct the pump?

high quality rubber slurry pump factory...

high quality rubber slurry pump factory 【high quality rubber slurry pump factory】

Read MoreAuxiliary equipment

high quality rubber slurry pump factory...

high quality rubber slurry pump factory 【high quality rubber slurry pump factory】

Read MoreThe impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

high quality rubber slurry pump factory...

high quality rubber slurry pump factory 【high quality rubber slurry pump factory】

Read More

Popular articles

- Pumps with replaceable parts and components can have an unlimited service life. A high quality customised slurry pump with replaceable parts can last you a lifetime and should therefore be considered as a very reliable long-term investment.

- Settling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

- 1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

- A typical pump solution for this application is to install a hard metal >slurry pump to withstand these types of conditions. Hard metal pumps need to be able to withstand the most severe abrasive slurry service and they also need to be designed to be extremely easy to maintain and safe.

- There are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

- target=_blank>Slurry Pump

Latest articles

-

A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

-

There are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

-

In a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

-

Slurry Pump

-

If you want to know more information about the best heavy duty slurry pump, welcome to >contact us today or request a quote.

-

Choosing the right target=_blank title=Slurry Pump>slurry pump for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share them with you.

Links

Ideally, thickness usually determines the overall appearance and durability of these aluminum profiles.

Heritage and Restoration Projects: Aluminium window profiles can be custom-made to match the look and feel of traditional window designs. This makes them suitable for heritage buildings and restoration projects where authenticity is important.

- Clear Coat (just a clear coat, makes spindles look rustic underneath. Shows flaws of metal)

- In today's fast-paced world, the need for secure storage solutions has never been greater. Whether you're a homeowner, a business owner, or simply someone who values the safety of their personal belongings, a steel key box can provide peace of mind and added security.

- The process of sliding door roller fitting begins with a meticulous assessment of the door's weight and dimensions. This preliminary step ensures the selection of the appropriate rollers that can support the door's weight while ensuring smooth operation. Rollers come in various types, including top hung and bottom rolling systems, each designed to cater to different door designs and requirements.

Made from sturdy metal materials, these boxes are designed to withstand the rigors of daily use and provide long-lasting protection for your valuables Made from sturdy metal materials, these boxes are designed to withstand the rigors of daily use and provide long-lasting protection for your valuables

Made from sturdy metal materials, these boxes are designed to withstand the rigors of daily use and provide long-lasting protection for your valuables Made from sturdy metal materials, these boxes are designed to withstand the rigors of daily use and provide long-lasting protection for your valuables small metal lock box with key. This durability ensures that your lock box will continue to keep your belongings safe and secure for years to come.

small metal lock box with key. This durability ensures that your lock box will continue to keep your belongings safe and secure for years to come.Durability and Longevity

In winter, they can help retain heat inside your home by providing an extra layer of insulation against the cold weather In winter, they can help retain heat inside your home by providing an extra layer of insulation against the cold weather

In winter, they can help retain heat inside your home by providing an extra layer of insulation against the cold weather In winter, they can help retain heat inside your home by providing an extra layer of insulation against the cold weather windows roller. This not only saves money on energy bills but also reduces your carbon footprint.

windows roller. This not only saves money on energy bills but also reduces your carbon footprint.Adjusting the rollers on sliding doors is a straightforward process that can greatly enhance their functionality. By following the steps outlined above, you can ensure that your sliding door operates smoothly and lasts for many years. Regular maintenance, including cleaning and lubricating, will further ensure optimal performance. With a little time and effort, you can keep your sliding doors in excellent condition and enjoy their benefits throughout your home.

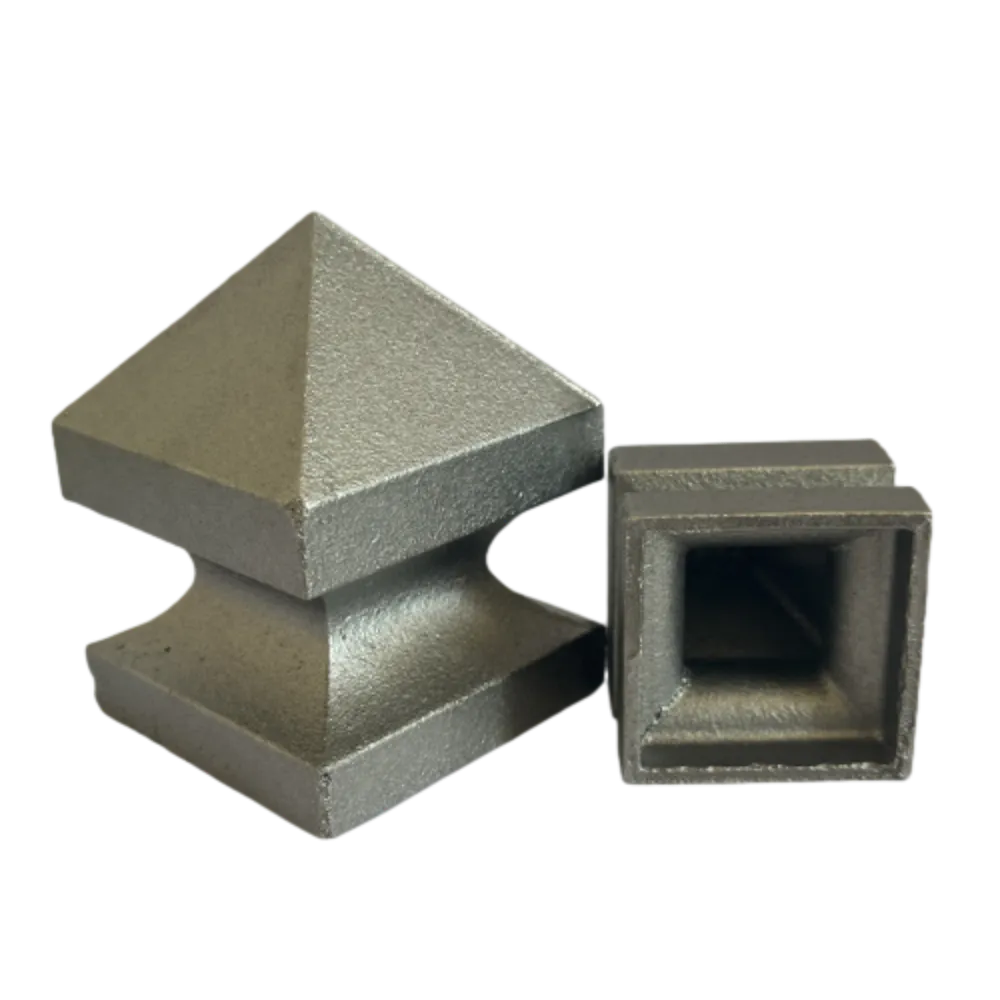

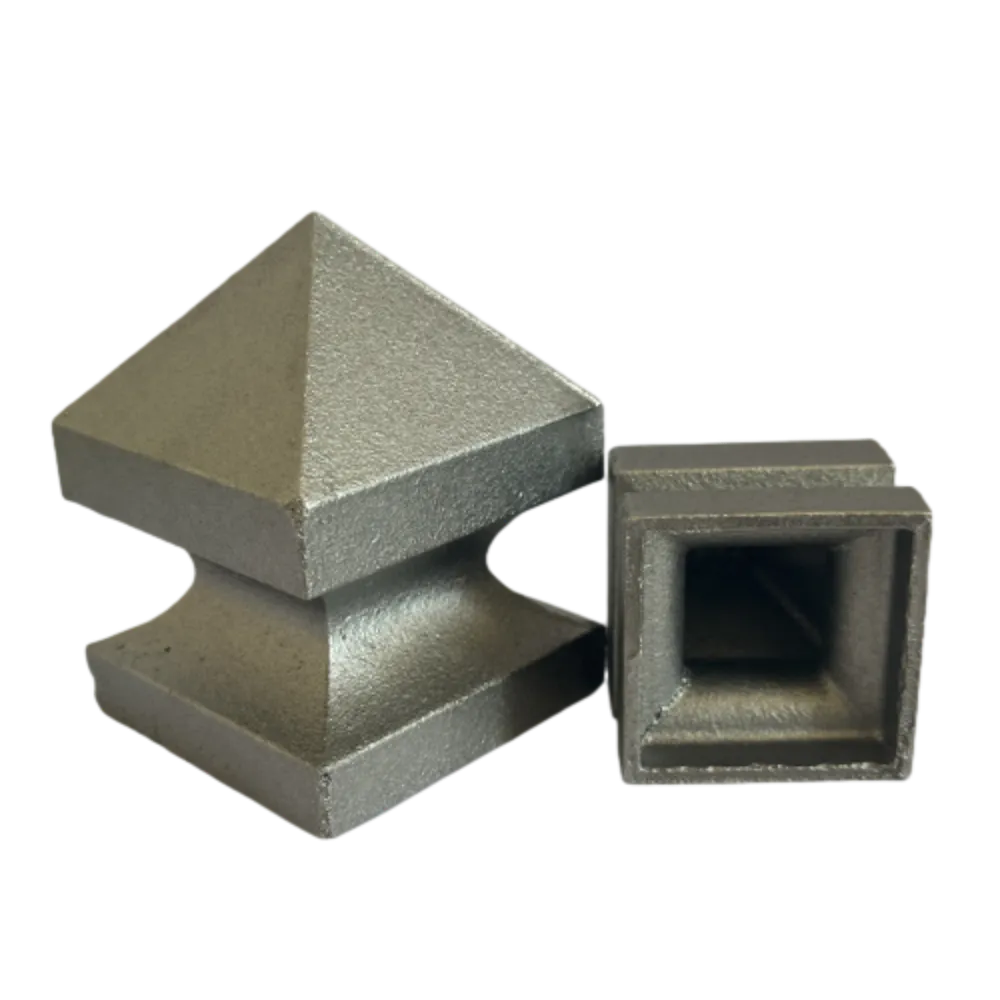

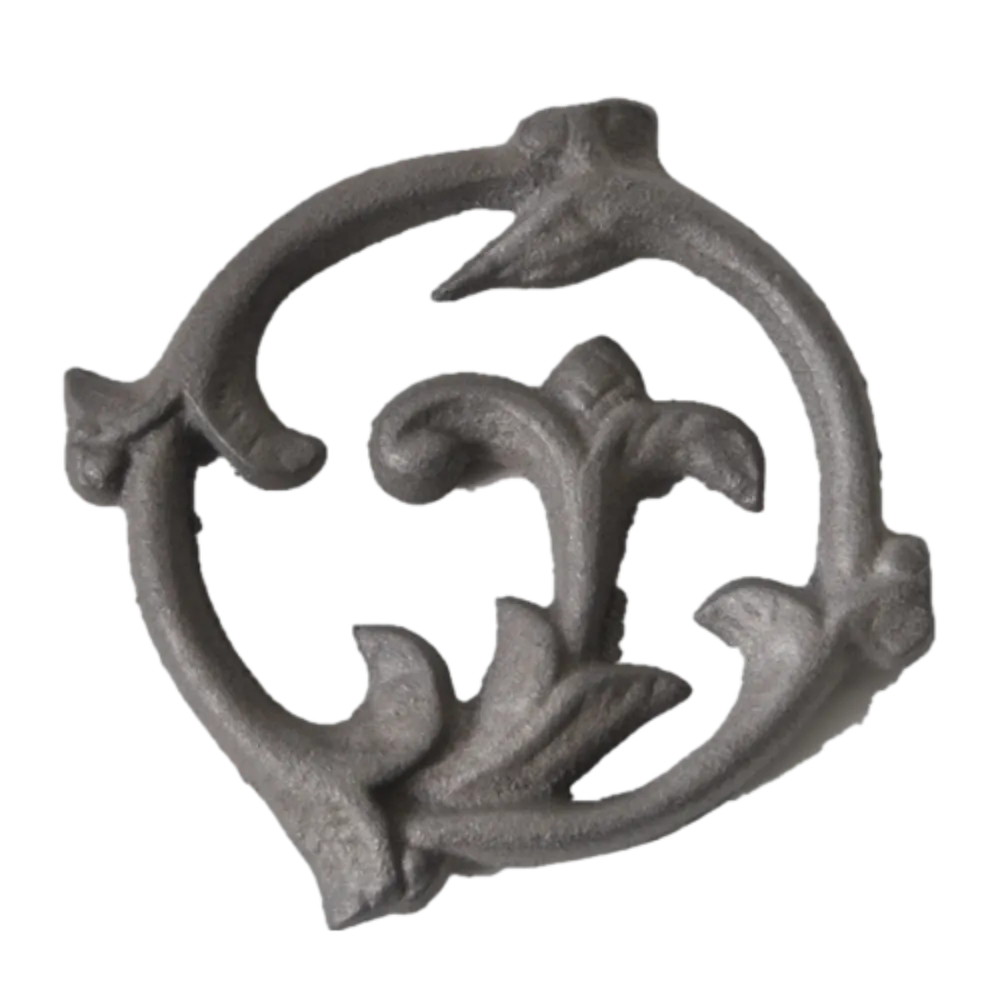

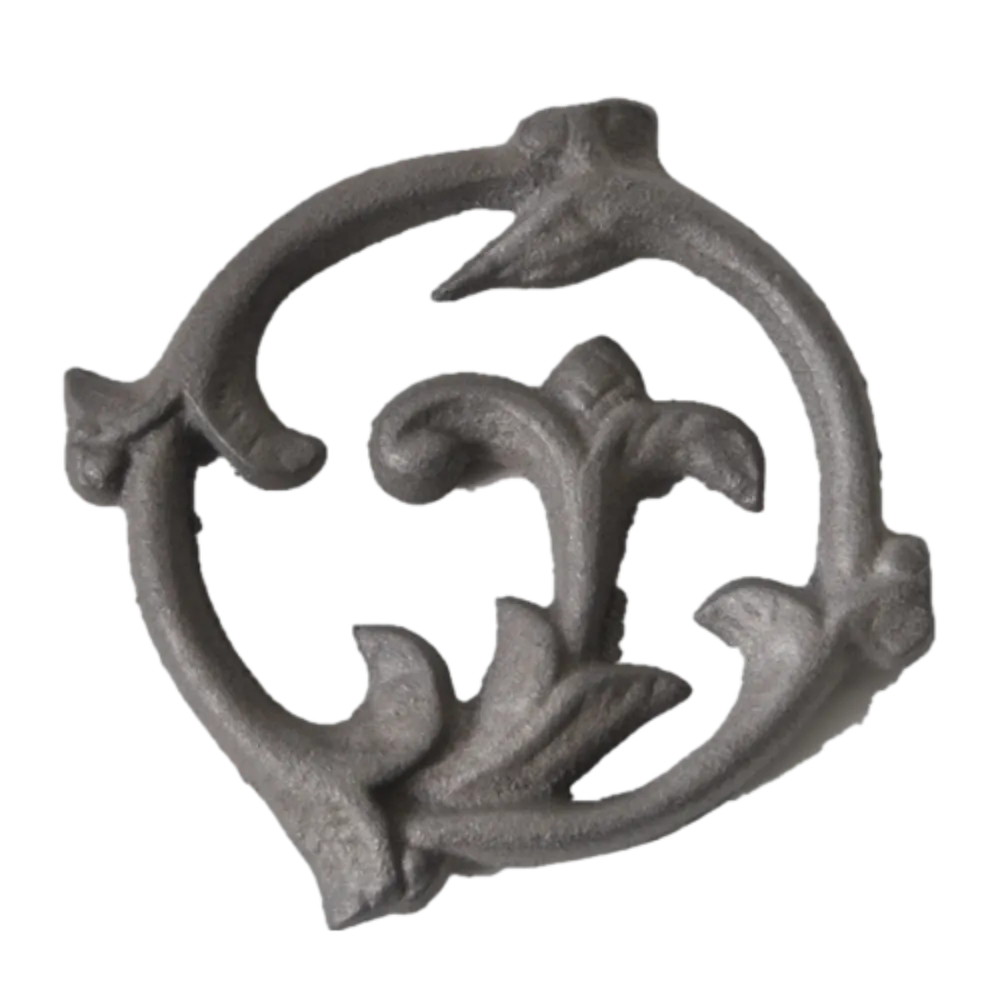

Understanding the Components of a Rod Iron Fence

window aluminium profile. Available in a wide range of finishes, from natural metallic shades to vibrant hues, they can easily complement any interior or exterior design. Moreover, their sleek and modern appearance adds a touch of sophistication to any space.

window aluminium profile. Available in a wide range of finishes, from natural metallic shades to vibrant hues, they can easily complement any interior or exterior design. Moreover, their sleek and modern appearance adds a touch of sophistication to any space.Today, the legacy of head spearing lives on primarily through historical accounts, anthropological studies, and preserved artifacts. Museums showcase these ancient weapons, providing a window into a past where such practices were integral to societal norms. Furthermore, the remnants of head spearing traditions have inspired contemporary art and literature, serving as a reminder of the complex tapestry of human history.

aluminium sliding roller. Whether used in machinery that requires parts to remain stationary until activated or in conveyance systems that transport materials across large distances, these rollers provide the necessary support. They are particularly effective in linear motion applications, where their low-friction properties allow for smooth gliding actions that prevent jerky movements or misalignments.

aluminium sliding roller. Whether used in machinery that requires parts to remain stationary until activated or in conveyance systems that transport materials across large distances, these rollers provide the necessary support. They are particularly effective in linear motion applications, where their low-friction properties allow for smooth gliding actions that prevent jerky movements or misalignments. Turning the screws clockwise or counterclockwise will either raise or lower the door, helping to correct any imbalance Turning the screws clockwise or counterclockwise will either raise or lower the door, helping to correct any imbalance

Turning the screws clockwise or counterclockwise will either raise or lower the door, helping to correct any imbalance Turning the screws clockwise or counterclockwise will either raise or lower the door, helping to correct any imbalance adjusting sliding doors roller.

adjusting sliding doors roller. It can be used in a variety of window and door designs, from traditional to modern, and can be painted or coated to match the existing color scheme of the building It can be used in a variety of window and door designs, from traditional to modern, and can be painted or coated to match the existing color scheme of the building

It can be used in a variety of window and door designs, from traditional to modern, and can be painted or coated to match the existing color scheme of the building It can be used in a variety of window and door designs, from traditional to modern, and can be painted or coated to match the existing color scheme of the building aluminum glazing bead. This allows for customization and personalization while still maintaining the functionality and performance of the window or door.

aluminum glazing bead. This allows for customization and personalization while still maintaining the functionality and performance of the window or door.Sliding door runner wheels are designed to facilitate the smooth movement of sliding doors along their tracks. These wheels are typically mounted on the top or bottom of the door and roll along a rail or track. Properly functioning runner wheels ensure that doors open and close effortlessly, which is particularly important in high-traffic areas. Over time, however, these wheels can wear down, leading to frustrating sticking or off-track situations.

OEM or ODM is available, please send us your drawing