china filter press slurry pump

Latest articles

Typically, slurries are.

china filter press slurry pump...

china filter press slurry pump 【china filter press slurry pump】

Read More1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

china filter press slurry pump...

china filter press slurry pump 【china filter press slurry pump】

Read MoreDetermine the nature of the material to be pumped

china filter press slurry pump...

china filter press slurry pump 【china filter press slurry pump】

Read MoreCustomised solutions

china filter press slurry pump...

china filter press slurry pump 【china filter press slurry pump】

Read MoreSlurry pumps can be used for.

china filter press slurry pump...

china filter press slurry pump 【china filter press slurry pump】

Read MoreRubber lined pumps offer many advantages

china filter press slurry pump...

china filter press slurry pump 【china filter press slurry pump】

Read MoreSlurry Pump Considerations

china filter press slurry pump...

china filter press slurry pump 【china filter press slurry pump】

Read MoreAny type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

china filter press slurry pump...

china filter press slurry pump 【china filter press slurry pump】

Read MoreHow does a dredge pump work?

china filter press slurry pump...

china filter press slurry pump 【china filter press slurry pump】

Read MoreSlurry pump seals

china filter press slurry pump...

china filter press slurry pump 【china filter press slurry pump】

Read More

Popular articles

- Typical Applications of slurry pump

- The FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

- A quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

- What is a dredging pump?

- A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right >pump. In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

- Selecting a dredge pump

Latest articles

-

Fine-grained sand can be extremely abrasive and typically wears slurry pumps quickly. Characteristics of coarse aggregates that can affect pump performance are size, shape and surface texture, as well as gradual changes in particle size, while fine materials can create excessive friction in the pipe.

-

For certain types of slurry pumping conditions, positive displacement pumps may be a more suitable option than centrifugal pumps.

-

The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

-

Critical to the engineering of the pump are heavy duty bearing frames and shafts, extra thick wall sections and easily replaceable wear parts. Total life cycle cost considerations are critical when specifying pumps for severe operating conditions, such as FGD service. High chrome pumps are ideal due to the corrosive pH of the slurry.

-

>Slurry Pump

-

Choosing the right target=_blank title=Slurry Pump>slurry pump for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share them with you.

Links

Üçüncüsü, istehsalçı və təchizatçının seçimi də qiymətə təsir edən bir amildir. Tanınmış və etibarlı istehsalçılar, yüksək keyfiyyətli məhsullar təqdim edərkən, onların qiyməti də müvafiq olaraq yüksək ola bilər. Bəzi müştərilər, ucuz məhsul axtararkən keyfiyyəti düşürməyi gözdən keçirirlər, lakin bu yanaşma uzunmüddətli perspektivdə daha böyük xərclərə səbəb ola bilər.

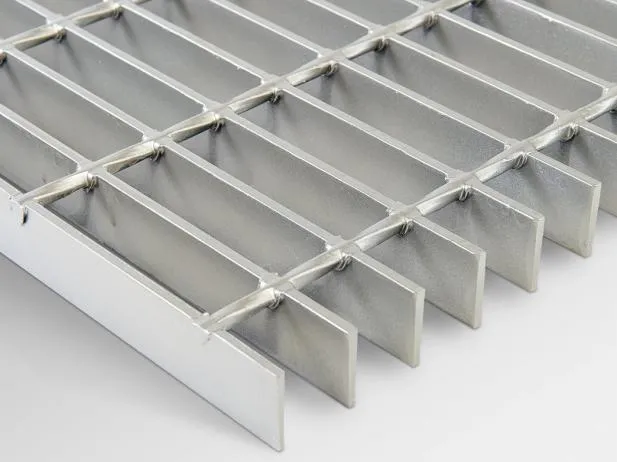

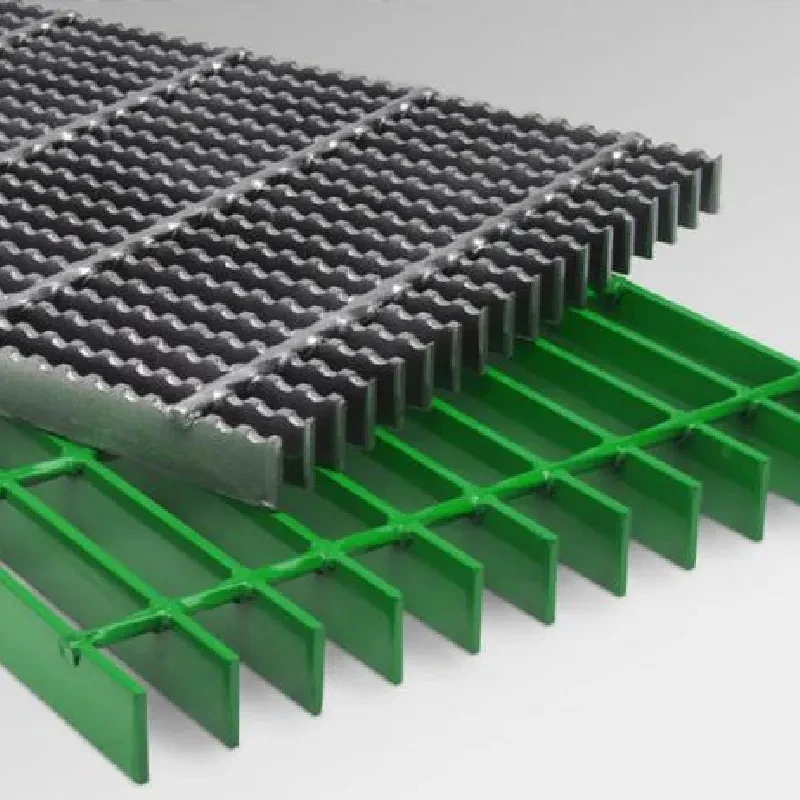

La versatilidad de las rejillas de suelo de metal de alta resistencia también se manifiesta en su variedad de estilos y acabados. Pueden ser personalizadas para adaptarse a diversas necesidades estéticas y funcionales. Desde rejillas con aberturas específicas para drenajes hasta aquellas que permiten la ventilación adecuada, las opciones son amplias. Esto permite a los diseñadores e ingenieros integrarlas sin esfuerzo en proyectos que requieren tanto funcionalidad como estética.

Types of Shale Shaker Screens

Las rejillas de acero mild de alta resistencia son un componente esencial en diversas industrias, incluyendo la construcción, la minería, la petroquímica y muchas más. Este tipo de rejilla, fabricada con acero laminado en caliente, se caracteriza por su durabilidad, resistencia y versatilidad, lo que la convierte en una opción popular para aplicaciones donde la seguridad y la eficiencia son primordiales.

Edelstahlbodengitter – Die perfekte Lösung für industriellen und gewerblichen Einsatz

Pricing and Value

Choosing the right shale shaker screen mesh and maintaining it properly are essential for ensuring optimal.

Важно отметить, что серрейторные решетки могут быть выполнены в различных дизайнах и цветах, что позволяет легко интегрировать их в общее оформление помещения или здания. Это позволяет не только обеспечить безопасность, но и улучшить эстетическое восприятие пространства.

En resumen, las rejillas de acero mild de alta resistencia son una solución confiable y eficiente para una amplia gama de aplicaciones industriales y de construcción. Su capacidad para soportar cargas pesadas, su versatilidad en el diseño, su facilidad de instalación y su resistencia a la corrosión las convierten en la elección ideal para proyectos que requieren seguridad y durabilidad. Al considerar la opción de rejillas para sus instalaciones, es esencial elegir productos de alta calidad que cumplan con los estándares necesarios para garantizar un rendimiento óptimo a lo largo de los años.

The Advantages of Steel Mesh Flooring

धातु की ग्रेटिंग का वजन उसके निर्माण में उपयोग होने वाली सामग्री, ग्रेटिंग की मोटाई, और उस ग्रेटिंग का आकार निर्धारित करता है। यदि ग्रेटिंग की मोटाई अधिक है, तो उसका वजन भी अधिक होगा। इसलिए, जब किसी परियोजना के लिए धातु की ग्रेटिंग का चयन किया जाता है, तो इन सभी पहलुओं को ध्यान में रखना आवश्यक होता है।

metal grating weight

4. Maintenance Regular maintenance of trench drains is essential, but using quality covers can minimize the amount of debris that enters the system. This ease of maintenance not only saves time but also ensures that the drainage system functions effectively throughout the swimming season.

In various industrial settings, the demand for robust flooring solutions is paramount. Heavy duty metal floor grates have emerged as an essential component in many applications, combining strength, durability, and safety. Unlike traditional flooring options, floor grates offer superior drainage, ventilation, and can withstand significant impact, making them ideal for factories, warehouses, and outdoor environments.

Un autre facteur à considérer est le volume d'achat. Les entreprises qui commandent de grandes quantités de grilles métalliques peuvent bénéficier de réductions de prix en raison des économies d'échelle. Dans le même temps, les petites entreprises ou les particuliers peuvent se voir proposer des tarifs moins intéressants, entraînant une différence significative dans le coût final. Il est donc prudent d’évaluer les besoins avant de passer une commande pour éviter des dépenses inutiles.