china sand pump factories

Latest articles

Submersible Slurry Pump

china sand pump factories...

china sand pump factories 【china sand pump factories】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

china sand pump factories...

china sand pump factories 【china sand pump factories】

Read MoreHow Slurry Pumps Differ From Standard Pumps?

china sand pump factories...

china sand pump factories 【china sand pump factories】

Read More>Dredge Pump

china sand pump factories...

china sand pump factories 【china sand pump factories】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

china sand pump factories...

china sand pump factories 【china sand pump factories】

Read MoreRubber Lined Slurry Pump

china sand pump factories...

china sand pump factories 【china sand pump factories】

Read MoreMixers can also help agitators when pumping very dense particles. In applications where the tank is small and/or where pumping is desired to lower the water level in the tank, a slurry pump with an internal cooling system should be considered to avoid overheating of the stator (when the water level gets low). When pumping sediment from a dam or lagoon, consider the use of a raft unit, which is a submersible device. Agitators are recommended, as well as one or more mixers that can be mounted on the raft or pump to resuspend particles for successful pumping of particles.

china sand pump factories...

china sand pump factories 【china sand pump factories】

Read MoreWhat style of pump is suitable?

china sand pump factories...

china sand pump factories 【china sand pump factories】

Read MoreAs described below, there are several >types of pumps that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

china sand pump factories...

china sand pump factories 【china sand pump factories】

Read MoreVertical Slurry Pumps Pump Sewage More Efficiently

china sand pump factories...

china sand pump factories 【china sand pump factories】

Read More

Popular articles

- >Slurry Pump

- The same point of slurry pump and mud pump

- A typical pump solution for this application is to install a hard metal >slurry pump to withstand these types of conditions. Hard metal pumps need to be able to withstand the most severe abrasive slurry service and they also need to be designed to be extremely easy to maintain and safe.

- High head (i.e. the height to which the pump can move the liquid)

- Slurry Pump

- Aier Machinery's team of consultants are on hand to provide you with a solution to your needs. Whether you are planning to purchase a slurry pump or need spare parts for an existing pump, we will help you determine your needs and provide advice on fine-tuning your equipment to your specific application.

Latest articles

-

Pumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.

-

Larger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

-

The basic mechanical seal flushing programme is very simple. It requires that a clear/clean fluid (usually water) is introduced into the space between the actual seal and the impeller side outlet restriction. The flushing fluid is introduced at a pressure higher than the pumping pressure, thus ensuring positive outflow/flushing of the mechanical seal and a clean operating environment.

-

When slurry pump working, which is the motor drives the impeller rotation. That is the impeller on the slurry work which increases the kinetic energy of the slurry. At the same time, the slurry flows to the edge of the impeller due to inertia and is discharged from the discharge pipe at a high speed.

-

Slurry pump seals

-

There are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

This not only enhances the energy efficiency of a building but also contributes to reduced energy bills and a smaller carbon footprint This not only enhances the energy efficiency of a building but also contributes to reduced energy bills and a smaller carbon footprint

This not only enhances the energy efficiency of a building but also contributes to reduced energy bills and a smaller carbon footprint This not only enhances the energy efficiency of a building but also contributes to reduced energy bills and a smaller carbon footprint

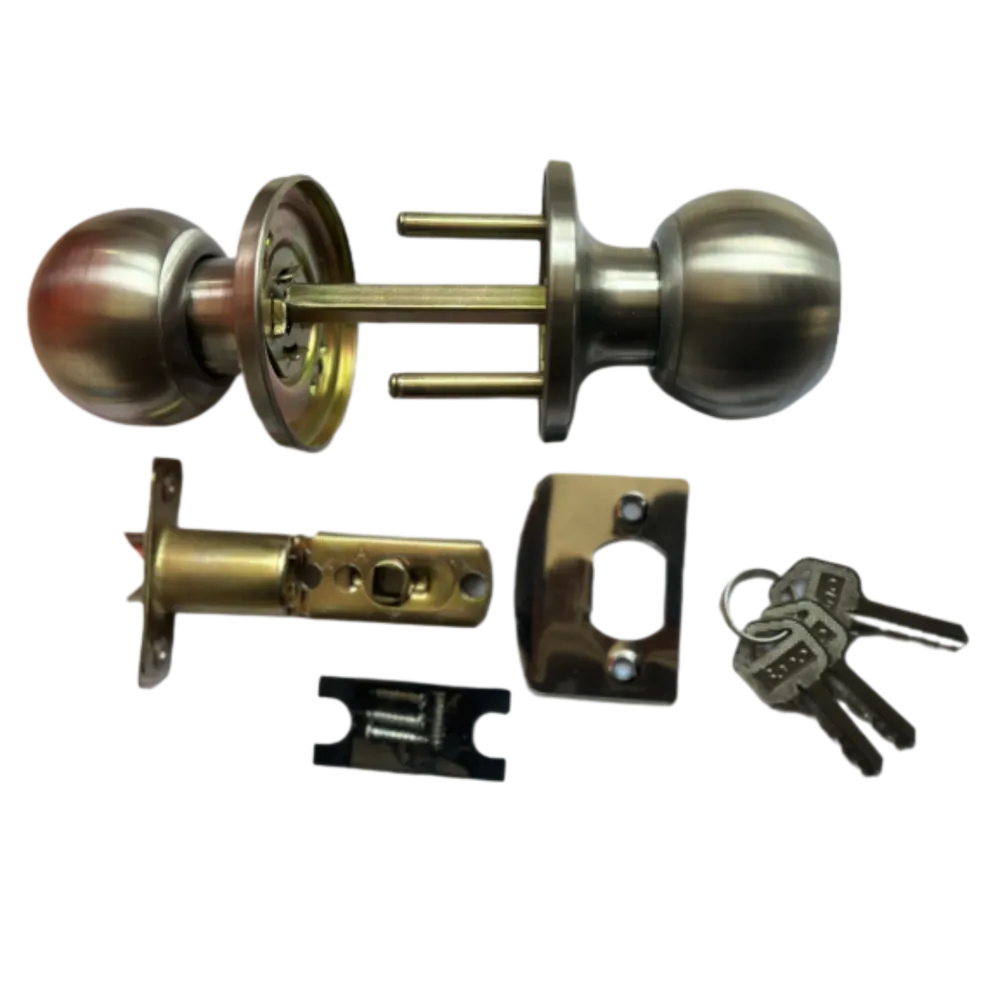

Together, they create a harmonious partnership that enhances the door's performance and longevity Together, they create a harmonious partnership that enhances the door's performance and longevity

Together, they create a harmonious partnership that enhances the door's performance and longevity Together, they create a harmonious partnership that enhances the door's performance and longevity

Furthermore, the wheels are often equipped with seals and gaskets that not only enhance insulation but also prevent dust and moisture infiltration, contributing to a cleaner and healthier living space Furthermore, the wheels are often equipped with seals and gaskets that not only enhance insulation but also prevent dust and moisture infiltration, contributing to a cleaner and healthier living space

Furthermore, the wheels are often equipped with seals and gaskets that not only enhance insulation but also prevent dust and moisture infiltration, contributing to a cleaner and healthier living space Furthermore, the wheels are often equipped with seals and gaskets that not only enhance insulation but also prevent dust and moisture infiltration, contributing to a cleaner and healthier living space Unlike other materials that require frequent care and attention, these panels need only an occasional wipe down to keep them looking pristine Unlike other materials that require frequent care and attention, these panels need only an occasional wipe down to keep them looking pristine

Unlike other materials that require frequent care and attention, these panels need only an occasional wipe down to keep them looking pristine Unlike other materials that require frequent care and attention, these panels need only an occasional wipe down to keep them looking pristine Whether it's a casement, sliding, tilt-turn, or fixed window type, aluminium frames can be tailored to fit different architectural styles, sizes, and shapes Whether it's a casement, sliding, tilt-turn, or fixed window type, aluminium frames can be tailored to fit different architectural styles, sizes, and shapes

Whether it's a casement, sliding, tilt-turn, or fixed window type, aluminium frames can be tailored to fit different architectural styles, sizes, and shapes Whether it's a casement, sliding, tilt-turn, or fixed window type, aluminium frames can be tailored to fit different architectural styles, sizes, and shapes