sand suction dredge pump manufacturers

Latest articles

Corrosiveness of the liquid or slurry mixture: More corrosive slurries will wear pump components faster and may dictate the choice of pump manufacturing materials.

sand suction dredge pump manufacturers...

sand suction dredge pump manufacturers 【sand suction dredge pump manufacturers】

Read MoreAre the pump discharge components suitable for the slurry being pumped?

sand suction dredge pump manufacturers...

sand suction dredge pump manufacturers 【sand suction dredge pump manufacturers】

Read MoreAs new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumpsxa0help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

sand suction dredge pump manufacturers...

sand suction dredge pump manufacturers 【sand suction dredge pump manufacturers】

Read More1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

sand suction dredge pump manufacturers...

sand suction dredge pump manufacturers 【sand suction dredge pump manufacturers】

Read MoreChoosing the right target=_blank title=Slurry Pump>slurry pump for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share them with you.

sand suction dredge pump manufacturers...

sand suction dredge pump manufacturers 【sand suction dredge pump manufacturers】

Read MoreOne of the most frequently asked questions from our team of pump experts is: How do I pump slurry? With this in mind, our team of experts have provided a useful guide to pumping slurry.

sand suction dredge pump manufacturers...

sand suction dredge pump manufacturers 【sand suction dredge pump manufacturers】

Read Morehow-does-a-dredge-pump-work

sand suction dredge pump manufacturers...

sand suction dredge pump manufacturers 【sand suction dredge pump manufacturers】

Read MoreFind the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

sand suction dredge pump manufacturers...

sand suction dredge pump manufacturers 【sand suction dredge pump manufacturers】

Read MoreAs wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

sand suction dredge pump manufacturers...

sand suction dredge pump manufacturers 【sand suction dredge pump manufacturers】

Read MoreAIER will always strive to be your common sense slurry pump and parts supplier in a complex world!

sand suction dredge pump manufacturers...

sand suction dredge pump manufacturers 【sand suction dredge pump manufacturers】

Read More

Popular articles

- In dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

- Rubber Lined Slurry Pump

- Slurry pump considerations

- Improved flow control

- Light-duty Slurry Pump

- AIER will always strive to be your common sense slurry pump and parts supplier in a complex world!

Latest articles

-

If youve ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. Theres no doubt that the slurry on the pump is hard. But the more you know about whats being pumped, the better your pump selection will be, resulting in longer mean time between failures.xa0Next, the , slurry pump supplier, will share the following content with you.

-

Traditionally, centrifugal pumps are used to pump highly abrasive slurries. Centrifugal pumps use the force generated by the rotating impeller to impinge kinetic energy into the slurry.

-

how-does-a-dredge-pump-work

-

Again, to meet life cycle cost considerations, pumps should be equipped with large diameter impellers for lower operating speeds and longer wear life, as well as field replaceable rubber liners that can be bolted on for quick maintenance. In a typical coal-fired power plant, two to five pumps will be used in each spray tower.

-

Slurry Pump

-

There is a better way to pump sewage, overflows and other collected dirty water around the plant.

Links

Aluminum bar grating offers a variety of options to suit different application needs. The flush top design provides a smooth surface for walking, while the rectangular bar and I-bar options offer enhanced strength and stability. Plank grating features a durable and slip-resistant surface, making it ideal for industrial settings.

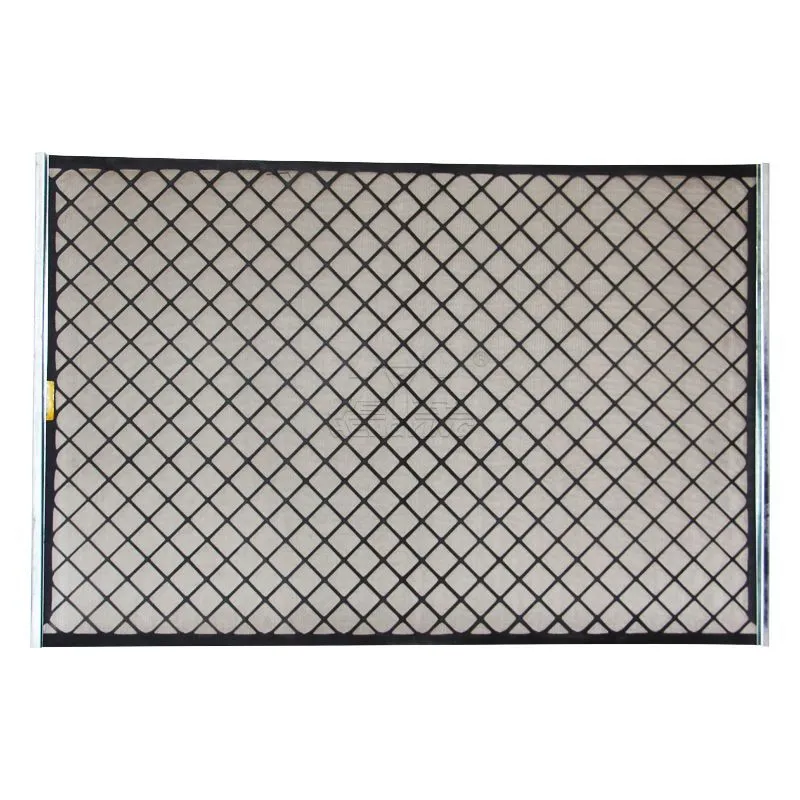

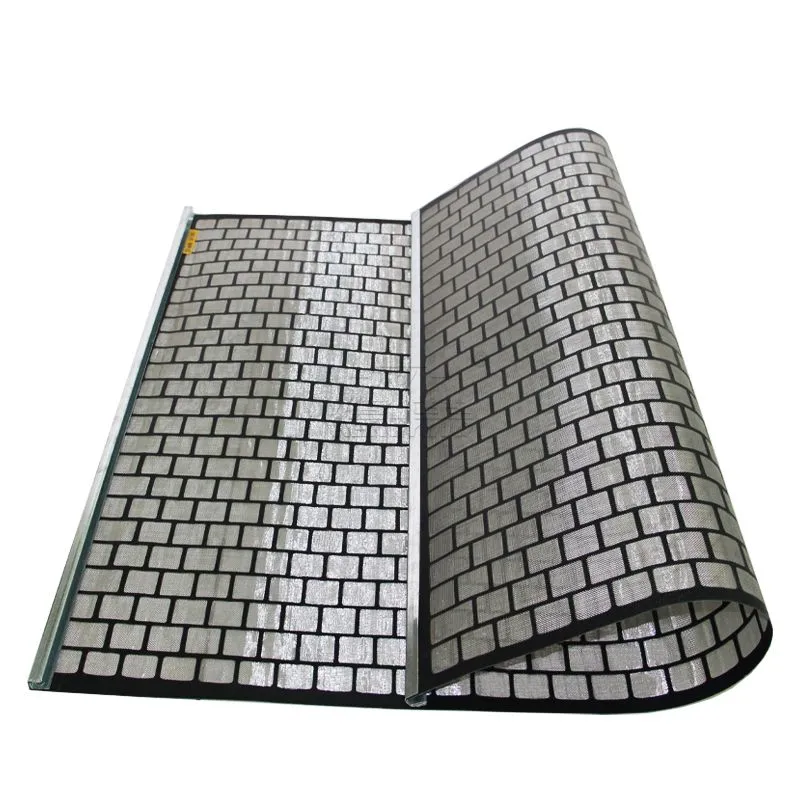

Material Compatibility: The screen material should be compatible with the drilling fluid and the environment in which it will be used. For example, screens.

Understanding Shaker Screens

Le Prix des Grilles Métalliques Un Aperçu

Galvanizli Izgara Maliyetleri Neden Önemlidir?

Sikkerhed er også et stort fokusområde ved brug af heavy duty steel grating. Det hjælper med at reducere risikoen for ulykker ved at give en stabil og skridsikker overflade, der kan modstå tunge belastninger. Dette er især vigtigt i områder med høj trafik eller i miljøer, hvor medarbejdere arbejder med tungt udstyr. Ved at implementere heavy duty steel grating kan virksomheder derfor forbedre sikkerheden og reducere risikoen for arbejdsulykker.