high quality cheap submersible pump for wastewater

Latest articles

>Vertical Slurry Pump

high quality cheap submersible pump for wastewater...

high quality cheap submersible pump for wastewater 【high quality cheap submersible pump for wastewater】

Read MoreSlurry Pump

high quality cheap submersible pump for wastewater...

high quality cheap submersible pump for wastewater 【high quality cheap submersible pump for wastewater】

Read More- Portable and low maintenance - There are no long or exposed mechanical shafts between the motor and worm gear, which makes the submersible pump more portable. In addition, because there are no long or exposed mechanical connections between the motor and worm gear, less maintenance is required and operating costs are significantly lower.

high quality cheap submersible pump for wastewater...

high quality cheap submersible pump for wastewater 【high quality cheap submersible pump for wastewater】

Read MoreWhat is 'slurry'?

high quality cheap submersible pump for wastewater...

high quality cheap submersible pump for wastewater 【high quality cheap submersible pump for wastewater】

Read MoreIs the discharge configuration suitable for abrasive slurries?

high quality cheap submersible pump for wastewater...

high quality cheap submersible pump for wastewater 【high quality cheap submersible pump for wastewater】

Read MoreNon-settling slurries consist of very fine particles that do not settle to the bottom of the pipe and do not settle for very long (i.e. weeks).

high quality cheap submersible pump for wastewater...

high quality cheap submersible pump for wastewater 【high quality cheap submersible pump for wastewater】

Read MoreIn this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

high quality cheap submersible pump for wastewater...

high quality cheap submersible pump for wastewater 【high quality cheap submersible pump for wastewater】

Read MoreThe concept of the >slurry pump and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

high quality cheap submersible pump for wastewater...

high quality cheap submersible pump for wastewater 【high quality cheap submersible pump for wastewater】

Read MoreTypically, slurries are.

high quality cheap submersible pump for wastewater...

high quality cheap submersible pump for wastewater 【high quality cheap submersible pump for wastewater】

Read MoreThe concept of the , slurry pump, and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

high quality cheap submersible pump for wastewater...

high quality cheap submersible pump for wastewater 【high quality cheap submersible pump for wastewater】

Read More

Popular articles

- 3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

- >Slurry Pump

- Process speed doesn’t have anything to do with choosing slurry pump impeller, but it does have an effect on the life of slurry pump impeller. It is important to find the sweet spot that allows the slurry pump to run as slow as possible, but fast enough to keep solids from settling and clogging. If pumping too fast, the slurry can quickly erode the impeller due to its abrasive nature. This is why it is important to select a larger impeller if possible.

- What is a slurry?

- Applications of Rubber Lined Slurry Pumps

- Mixers can also help agitators when pumping very dense particles. In applications where the tank is small and/or where pumping is desired to lower the water level in the tank, a slurry pump with an internal cooling system should be considered to avoid overheating of the stator (when the water level gets low). When pumping sediment from a dam or lagoon, consider the use of a raft unit, which is a submersible device. Agitators are recommended, as well as one or more mixers that can be mounted on the raft or pump to resuspend particles for successful pumping of particles.

Latest articles

-

On the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

-

WY type pump casing is made of abrasion resistant metal, impeller material can be abrasion resistant metal or rubber. The submerged parts of WYJ are all lined with rubber, for transfer corrosive slurry.

-

Our firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

-

Magnetite mixing

-

Applications of Rubber Lined Slurry Pumps

-

Is the discharge configuration suitable for abrasive slurries?

Links

- This is where 3M Scotchgard Tape comes into play. Its unique formulation and construction make it the ideal solution for containing amalgam during the amalgamation process. The tape is coated with a special adhesive that adheres firmly to the tooth surface, creating a secure barrier that prevents the amalgam from spreading or escaping.

- Moreover, yellow tape also finds use in emergency response scenarios. During disaster management or search and rescue operations, it can be employed to mark downed power lines or damaged electrical infrastructure, keeping first responders and civilians at bay until professional electricians arrive.

Hot-melt is a low-temperature melting plastic, which makes this adhesive have low temperature resistance. It also ages poorly (becoming brittle) and has low UV resistance. This rubber is used for low- to medium-duty carton sealing, low-temperature splicing as well as paper core starting applications.

Engineered to beat the heat.

One of the primary uses of temporary floor marking tape is to enhance safety. In industrial settings, for instance, color-coded tape can indicate pedestrian walkways, machinery zones, and emergency exits. By clearly marking these areas, businesses can significantly reduce the risk of accidents. Visual cues help employees understand where they can walk and where they should be cautious, promoting a safer work environment.

As mentioned, different colors indicate different types of electrical tape features. Many standard electrical tapes are sold in black, but you can find them in nearly every color. Choose the color of tape based on the application you will be using it for and its voltage, phase, and other electric-relevant information.

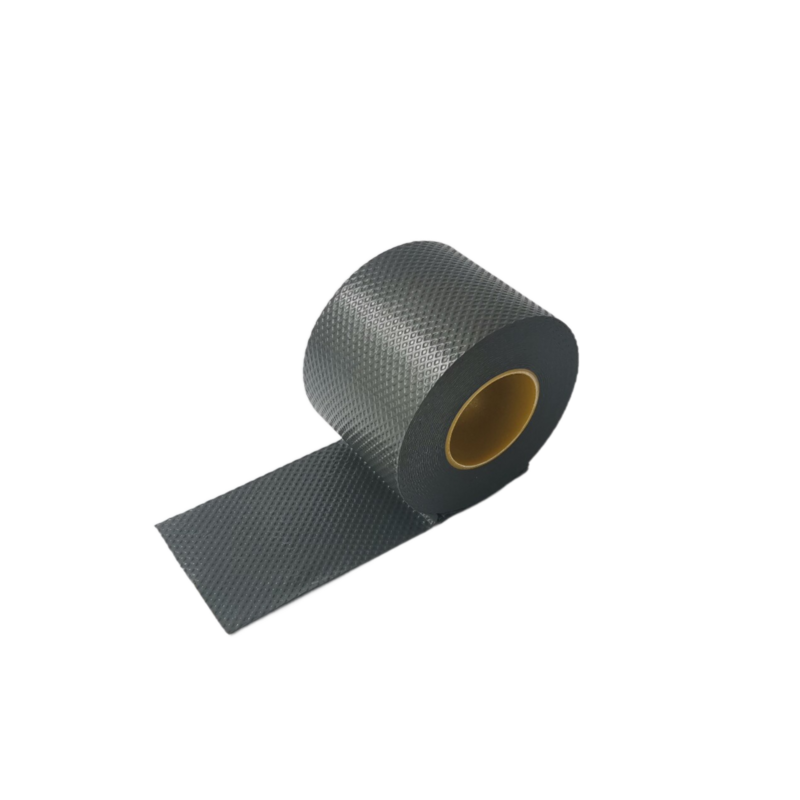

Polyethylene film tape (6350X) is a 5.5-mil thick tape with acrylic rubber adhesive. This film tape is flexible, conformable, durable, and chemical resistant. It is also resistant to tears, punctures, and abrasions, which makes it a good protective tape. It is also a good barrier tape for gas and moisture-proofing. Taping with polyethylene film tape produces a permanent bond with no edge bleeding.

If you have any questions, don't hesitate to reach out. We'll do what we can to help.

High voltage busbar insulation tape is specifically designed to withstand elevated voltage conditions. It serves as a barrier that isolates electrical conductors and protects against external factors such as moisture, dust, and chemical exposure.

black floor marking tape. It can be used to section off pet areas, create play zones for children, or even outline a home gym setup. Its durability and easy application make it an ideal solution for temporary or permanent floor markings.

black floor marking tape. It can be used to section off pet areas, create play zones for children, or even outline a home gym setup. Its durability and easy application make it an ideal solution for temporary or permanent floor markings.The rubber is water-resistant, a highly appreciated perk to those working in humid environments. Rubber tape is usually used for splicing and terminating wires or cables up to 69 kilovolts.