china sand slurry pump manufacturer

Latest articles

A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

china sand slurry pump manufacturer...

china sand slurry pump manufacturer 【china sand slurry pump manufacturer】

Read MoreAdvantages of rubber

china sand slurry pump manufacturer...

china sand slurry pump manufacturer 【china sand slurry pump manufacturer】

Read MoreSlurry Pump

china sand slurry pump manufacturer...

china sand slurry pump manufacturer 【china sand slurry pump manufacturer】

Read More>Slurry Pump

china sand slurry pump manufacturer...

china sand slurry pump manufacturer 【china sand slurry pump manufacturer】

Read MoreA slurry is any mixture of a fluid (such as water) and a powdery solid. Slurries are used as a convenient way to handle bulk solids in the mining, steel processing, foundry, power generation and, more recently, frac sand mining industries. Slurries typically behave like viscous viscous fluids, flowing under gravity, but can also be pumped as needed.

china sand slurry pump manufacturer...

china sand slurry pump manufacturer 【china sand slurry pump manufacturer】

Read MoreSelecting a dredge pump

china sand slurry pump manufacturer...

china sand slurry pump manufacturer 【china sand slurry pump manufacturer】

Read MoreOne of the most frequently asked questions from our team of pump experts is: How do I pump slurry?xa0With this in mind, our team of experts have provided a useful guide to pumping slurry.

china sand slurry pump manufacturer...

china sand slurry pump manufacturer 【china sand slurry pump manufacturer】

Read MoreWhat is a dredging pump?

china sand slurry pump manufacturer...

china sand slurry pump manufacturer 【china sand slurry pump manufacturer】

Read MoreAdvantages of rubber

china sand slurry pump manufacturer...

china sand slurry pump manufacturer 【china sand slurry pump manufacturer】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

china sand slurry pump manufacturer...

china sand slurry pump manufacturer 【china sand slurry pump manufacturer】

Read More

Popular articles

- Advantages of rubber

- Process speed doesn’t have anything to do with choosing slurry pump impeller, but it does have an effect on the life of slurry pump impeller. It is important to find the sweet spot that allows the slurry pump to run as slow as possible, but fast enough to keep solids from settling and clogging. If pumping too fast, the slurry can quickly erode the impeller due to its abrasive nature. This is why it is important to select a larger impeller if possible.

- Particle size, shape and hardness (impact on wear and corrosion potential of pump components)

- Working principle

- - Low noise level - Operating underwater results in low noise or even silent operation.

- Especially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

Latest articles

-

In AIER® slurry pumps, WY & WYJ sump pump are vertical centrifugal slurry pump, submerged for transfer abrasive, coarse particles and high density slurry. When working, it needs no seal water or any kind of seal. It can work well as well when suction volume is not enough.

-

The basic mechanical seal flushing programme is very simple. It requires that a clear/clean fluid (usually water) is introduced into the space between the actual seal and the impeller side outlet restriction. The flushing fluid is introduced at a pressure higher than the pumping pressure, thus ensuring positive outflow/flushing of the mechanical seal and a clean operating environment.

-

1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

-

Slurry Pump Selection

-

The rule of thumb for setting the water pressure is the same when using the pack box, whether flushing. Mud pump shut-off pressure plus 10% or plus 20 psi, whichever is greater. However, the flow rate is set differently.

-

Expertise and experience

Links

frp stair tread. This is especially advantageous in applications where heavy materials are not feasible or practical. The lightweight properties of FRP treads also make them a cost-effective option, as they can be easily handled by one person and do not require heavy machinery for installation.

hole drill bits. They are available in various sizes and lengths to suit different drilling depths.

fiberglass field tank. This flexibility makes fiberglass tanks suitable for a wide range of applications, from agricultural irrigation to chemical storage. Additionally, fiberglass tanks can be reinforced with additional layers for increased strength and protection in high-pressure or high-temperature environments.

hard rock drill bit. In construction, they facilitate the creation of foundations for towering skyscrapers and complex underground infrastructure. In mining, they aid in extracting valuable minerals from the earth's depths, contributing significantly to global economic growth.

hard rock drill bit. In construction, they facilitate the creation of foundations for towering skyscrapers and complex underground infrastructure. In mining, they aid in extracting valuable minerals from the earth's depths, contributing significantly to global economic growth. However, don't compromise on quality just to save a few dollars However, don't compromise on quality just to save a few dollars

However, don't compromise on quality just to save a few dollars However, don't compromise on quality just to save a few dollars cheap jack hammer for sale. Look for a model that offers good value for money and meets your requirements.

cheap jack hammer for sale. Look for a model that offers good value for money and meets your requirements.

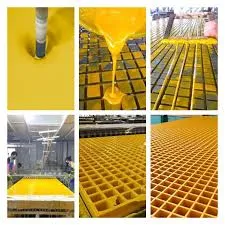

FRP grating is known for being durable in all kinds of environments. It can be exposed for long periods of time to the elements without showing any signs of wear and tear.

Similarly, models with lower noise levels, often preferred in residential areas, might come at a premium Similarly, models with lower noise levels, often preferred in residential areas, might come at a premium

Similarly, models with lower noise levels, often preferred in residential areas, might come at a premium Similarly, models with lower noise levels, often preferred in residential areas, might come at a premium pneumatic jack hammer price.

pneumatic jack hammer price. fiberglass stair tread. Unlike wood stair treads, which may require sanding, staining, or refinishing over time, fiberglass stair treads can be simply wiped clean with a damp cloth or mild detergent. This makes them a cost-effective choice for busy households or commercial buildings where maintenance time and costs are a concern.

fiberglass stair tread. Unlike wood stair treads, which may require sanding, staining, or refinishing over time, fiberglass stair treads can be simply wiped clean with a damp cloth or mild detergent. This makes them a cost-effective choice for busy households or commercial buildings where maintenance time and costs are a concern.Bullet Resistant Fiberglass Plate: