sewage drainage pump suppliers

Latest articles

The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of , submersible slurry pump, versus dry mount pumping and shares some general rules that apply to both applications.xa0Next, the , slurry pump manufacturer, xa0 will share the following content with you.

sewage drainage pump suppliers...

sewage drainage pump suppliers 【sewage drainage pump suppliers】

Read MoreFollow proper piping principles to ensure consistent and uniform delivery of mud to the pump.

sewage drainage pump suppliers...

sewage drainage pump suppliers 【sewage drainage pump suppliers】

Read MoreThe first major requirement for >slurry pumps is to provide adequate service life. The erosive and corrosive effects of slurries, such as the impact of high velocity flow of liquid/solid mixtures, can be really challenging. In many applications, some of the solids in the mixture are larger than the particles normally specified; therefore, the pump should be able to pass through them without causing any damage or operational problems.

sewage drainage pump suppliers...

sewage drainage pump suppliers 【sewage drainage pump suppliers】

Read MoreThese conditions include

sewage drainage pump suppliers...

sewage drainage pump suppliers 【sewage drainage pump suppliers】

Read MoreUnder ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

sewage drainage pump suppliers...

sewage drainage pump suppliers 【sewage drainage pump suppliers】

Read MoreTwo types of slurry are found in these industries.

sewage drainage pump suppliers...

sewage drainage pump suppliers 【sewage drainage pump suppliers】

Read MoreOn the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

sewage drainage pump suppliers...

sewage drainage pump suppliers 【sewage drainage pump suppliers】

Read MorePump selection for FGD

sewage drainage pump suppliers...

sewage drainage pump suppliers 【sewage drainage pump suppliers】

Read MoreSlurry pumps can be used for.

sewage drainage pump suppliers...

sewage drainage pump suppliers 【sewage drainage pump suppliers】

Read MorePumping slurry can cause excessive wear and tear on the pump and its components as the mud can clog the suction and discharge lines.

sewage drainage pump suppliers...

sewage drainage pump suppliers 【sewage drainage pump suppliers】

Read More

Popular articles

- AIER will always strive to be your common sense slurry pump and parts supplier in a complex world!

- As new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumps help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

- Process speed doesn’t have anything to do with choosing slurry pump impeller, but it does have an effect on the life of slurry pump impeller. It is important to find the sweet spot that allows the slurry pump to run as slow as possible, but fast enough to keep solids from settling and clogging. If pumping too fast, the slurry can quickly erode the impeller due to its abrasive nature. This is why it is important to select a larger impeller if possible.

- The Difference Between Flushing And Quenching in Slurry Pump Seals

- Slurry pump power adjustment

- Consider the pump components

Latest articles

-

Slurry pipe diameter.

-

The solution is to choose a >heavy duty slurry pump and, just as importantly, to use a custom built unit with replaceable parts. At Aier Machinery, building your custom slurry pump is one of our areas of expertise. We design your slurry pump to your specifications and application.

-

Slurry pumps are usually larger than standard pumps, have more horsepower and use stronger bearings and shafts. The most common >type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids pass through a standard centrifugal pump.

-

Slurry Pump

-

sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

-

A quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

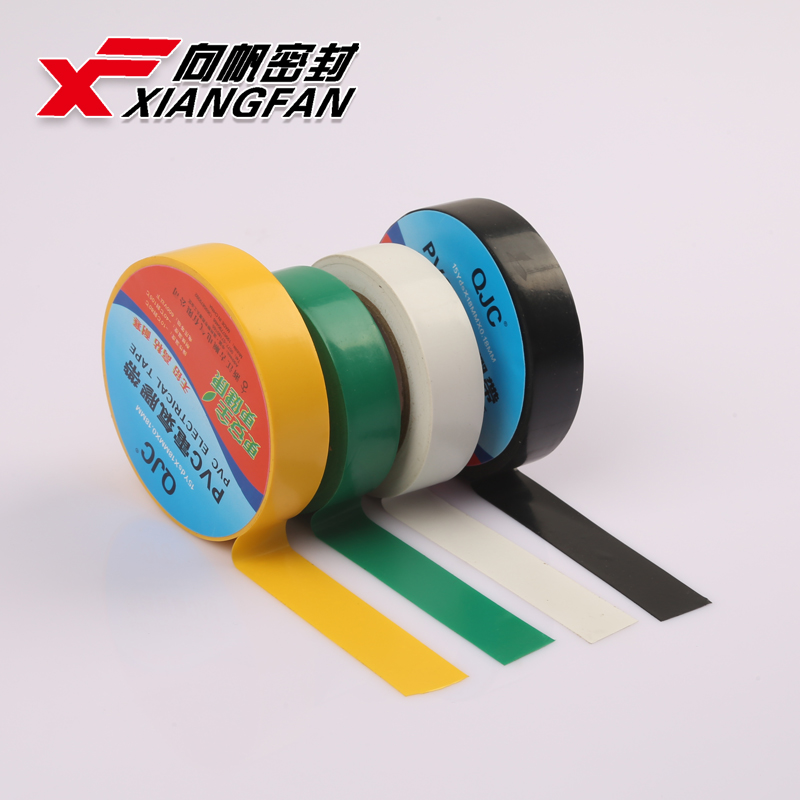

Whether you need to insulate a wire or secure loose wiring, electrical tape is up for the task. Just be sure to choose the right size and thickness for your project, and you’ll be good to go!

5. Ease of Use With no messy adhesives to deal with, self-fusing silicone tape is simple to apply. Users can easily wrap it around wires, connectors, and other components, ensuring a secure seal without complications.

In aerospace, it's vital for ensuring the safety and reliability of wiring systems in aircraft engines and avionics, where temperatures can soar In aerospace, it's vital for ensuring the safety and reliability of wiring systems in aircraft engines and avionics, where temperatures can soar

In aerospace, it's vital for ensuring the safety and reliability of wiring systems in aircraft engines and avionics, where temperatures can soar In aerospace, it's vital for ensuring the safety and reliability of wiring systems in aircraft engines and avionics, where temperatures can soar