china dredge pump parts manufacturers

Latest articles

Rubber lined pumps offer many advantages

china dredge pump parts manufacturers...

china dredge pump parts manufacturers 【china dredge pump parts manufacturers】

Read MoreDetermine the nature of the material to be pumped

china dredge pump parts manufacturers...

china dredge pump parts manufacturers 【china dredge pump parts manufacturers】

Read More3. Both pumps and motors are designed separately.

china dredge pump parts manufacturers...

china dredge pump parts manufacturers 【china dredge pump parts manufacturers】

Read More>Slurry Pump

china dredge pump parts manufacturers...

china dredge pump parts manufacturers 【china dredge pump parts manufacturers】

Read More>Dredge Pump

china dredge pump parts manufacturers...

china dredge pump parts manufacturers 【china dredge pump parts manufacturers】

Read MoreSlurry Pump

china dredge pump parts manufacturers...

china dredge pump parts manufacturers 【china dredge pump parts manufacturers】

Read MoreAs described below, there are several >types of pumps that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

china dredge pump parts manufacturers...

china dredge pump parts manufacturers 【china dredge pump parts manufacturers】

Read MoreAny type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

china dredge pump parts manufacturers...

china dredge pump parts manufacturers 【china dredge pump parts manufacturers】

Read MoreRubber lined pumps offer many advantages

china dredge pump parts manufacturers...

china dredge pump parts manufacturers 【china dredge pump parts manufacturers】

Read MoreSlurry Pump Selection

china dredge pump parts manufacturers...

china dredge pump parts manufacturers 【china dredge pump parts manufacturers】

Read More

Popular articles

- The concept of the >slurry pump and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

- The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

- A typical pump solution for this application is to install a hard metal >slurry pump to withstand these types of conditions. Hard metal pumps need to be able to withstand the most severe abrasive slurry service and they also need to be designed to be extremely easy to maintain and safe.

- Many types of pumps are used to pump slurry, but the most common slurry pump is the centrifugal pump. Centrifugal slurry pumps use centrifugal force from a rotating impeller to impinge kinetic energy on the slurry, similar to the way watery liquids pass through a standard centrifugal pump.

- The slurry pump is mainly used in the mining industry, its wear resistance is strong. So It conveys slurry that containing slag, but it can conveys mud. The mud pump is usually made of cast iron, the wear resistance of the pump is low. So the mud pumps often used for conveying mud or slurry containing suspended particles.

- Find the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

Latest articles

-

Aier Machinery has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

-

Adapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

-

- Pumping media where abrasive particles are present

-

A clear clean fluid supplied from an external source is normally used which is delivered to the main sealing surface on the fluid side of the sealing process. By using a closed gap throat bushing, the stuffing box can be back-pressurised to a higher pressure, ensuring that the flushing fluid does not flash across the seal face.

-

Slurry Pump

-

The design of the slurry pump is critical to ensure that the abrasive and often corrosive aspects of the slurry do not damage the impeller. In addition, slurries and sludges may contain large amounts of unforeseen solids, which will inevitably clog many types of pumps. Since most centrifugal pump impellers have very tight tolerances on the worm gear, the abrasive (and sometimes corrosive) nature of the slurry will quickly wear down the worm gear and destroy the tolerances. In turn, this causes the pump to lose suction. This can lead to extensive downtime of the slurry pump, as well as expensive maintenance and spare parts.

Links

- One of the standout features of aluminium sliding windows is their durability. Made from high-quality aluminium, these windows can withstand harsh weather conditions, including heavy rain, strong winds, and extreme temperatures. This makes them an ideal choice for coastal areas or regions with severe climates. Additionally, aluminium is a low-maintenance material, requiring only an occasional cleaning to keep it looking its best.

- In terms of energy efficiency, slim aluminium windows are designed to provide optimal insulation

Wrought iron: Fences, handrails, and balconies are handcrafted and customized with frame caps, fence post caps, scrolls, and collars.

Wrought iron fencing is a timeless element in the world of residential and commercial aesthetics. These fences are expertly crafted and add a posh touch to any property in addition to offering security and durability. We take great pride in being more than just fence installers at Iron Fence Master; we are artisans committed to enhancing your space with the classic beauty of wrought iron.

Bring Your Fence to Life With the Help of in Texas!

- Windows are the eyes of a building, offering a connection to the outside world while providing natural light and ventilation. In recent years, aluminium profiles have become a popular choice for window frames due to their numerous advantages over traditional materials like wood or steel. This article delves into the world of window aluminium profiles, exploring their significance and benefits in modern architectural design.

- On the other hand, the bulb with base approach involves acting quickly and decisively, without the need for extensive planning or preparation. This approach relies more on instinct and intuition, as well as the ability to adapt and react to changing circumstances on the fly. While this approach may be riskier and more unpredictable, it can also be highly effective in situations where quick action is needed and there is little time to strategize.

- The foundation of any iron gate is its frame, typically made from heavy-duty iron bars or tubes. This sturdy structure provides the necessary strength to withstand the test of time and weather conditions. The frame is then adorned with various decorative elements, such as scrolls, leaves, or geometric patterns, which are individually crafted and welded onto the frame. These intricate designs not only enhance the visual appeal but also reflect the skill and creativity of the blacksmith.

Aluminum profiles for windows and doors with mill finished is the raw state of the extruded material without any surface treatment.

This FAQs guide presents in-depth information regarding various aspects of these aluminum products.

Type II-Sulfuric Acid Anodize

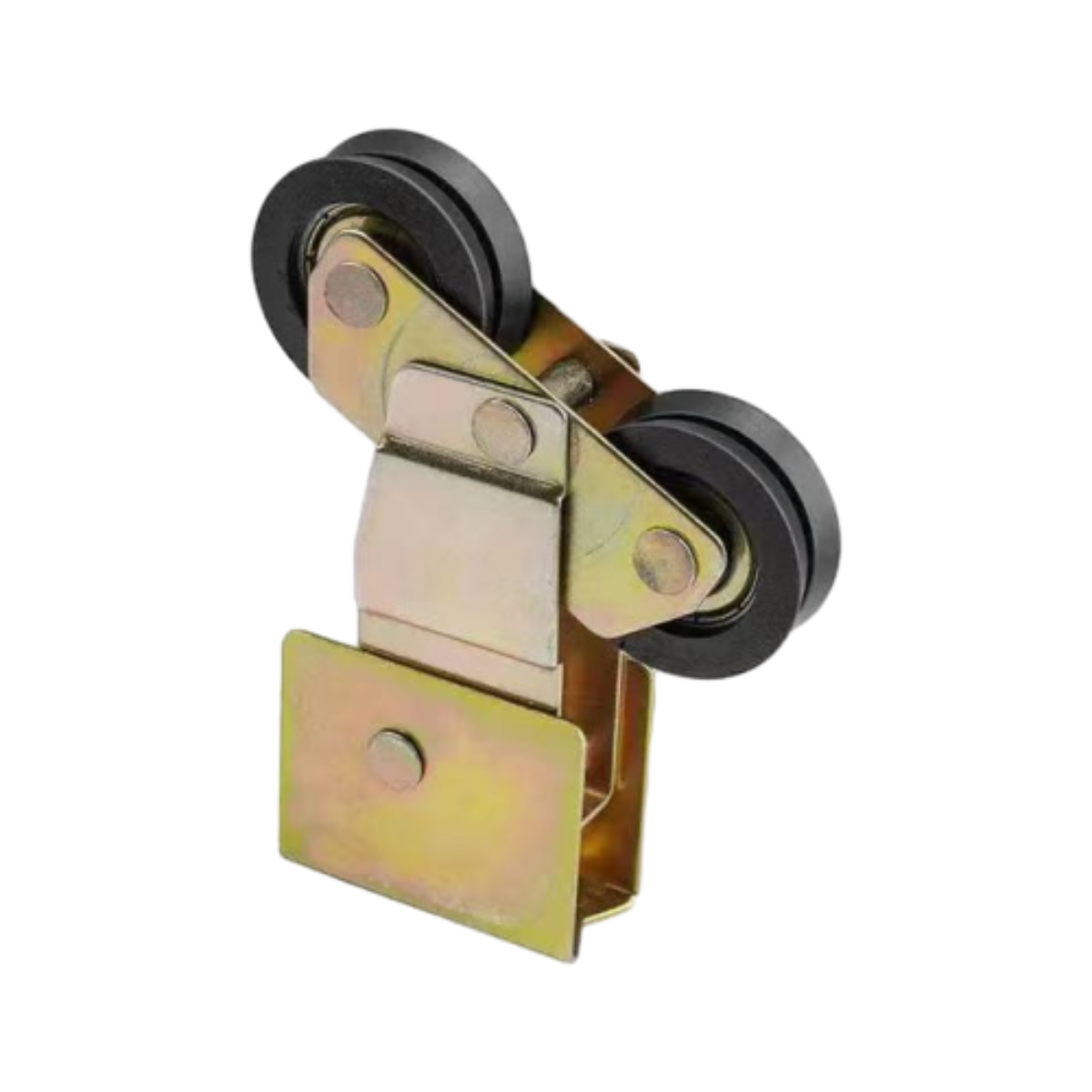

- The first step in fixing your screen door wheels is to remove the old ones. To do this, follow these instructions

- In terms of energy efficiency, slim aluminium windows are designed to provide optimal insulation

- The rolling window is directly exposed to the natural environment. The use of A-grade aluminum materials ensures the durability of the product.

The rust-resistant properties of the material further add to their longevity, making them a wise investment for both residential and commercial properties The rust-resistant properties of the material further add to their longevity, making them a wise investment for both residential and commercial properties

The rust-resistant properties of the material further add to their longevity, making them a wise investment for both residential and commercial properties The rust-resistant properties of the material further add to their longevity, making them a wise investment for both residential and commercial properties