open impeller slurry pump factories

Latest articles

Types of damage to slurry pumps

open impeller slurry pump factories...

open impeller slurry pump factories 【open impeller slurry pump factories】

Read MorePumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.

open impeller slurry pump factories...

open impeller slurry pump factories 【open impeller slurry pump factories】

Read MoreSlurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

open impeller slurry pump factories...

open impeller slurry pump factories 【open impeller slurry pump factories】

Read MoreNon-settling slurries consist of very fine particles that do not settle to the bottom of the pipe and do not settle for very long (i.e. weeks).

open impeller slurry pump factories...

open impeller slurry pump factories 【open impeller slurry pump factories】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

open impeller slurry pump factories...

open impeller slurry pump factories 【open impeller slurry pump factories】

Read More- Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

open impeller slurry pump factories...

open impeller slurry pump factories 【open impeller slurry pump factories】

Read MoreWhat is Heavy Duty Slurry Pump?

open impeller slurry pump factories...

open impeller slurry pump factories 【open impeller slurry pump factories】

Read MoreFirstly, analysing your duty helps us to determine whether you are using the type and size of pump best suited to your needs. Cavitation can occur due to surges; a very effective way to solve this problem is to install a choke on the pump head to increase the pressure on the casing, which then absorbs the surge, or to add a choke to the output to reduce the surge.

open impeller slurry pump factories...

open impeller slurry pump factories 【open impeller slurry pump factories】

Read MoreMake sure you follow the basic rules of pump piping.

open impeller slurry pump factories...

open impeller slurry pump factories 【open impeller slurry pump factories】

Read MoreA target=_blank title=Slurry Pump>slurry pump is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

open impeller slurry pump factories...

open impeller slurry pump factories 【open impeller slurry pump factories】

Read More

Popular articles

- The length of the piping. The longer the pipe, the more slurry-induced friction the pump needs to overcome.

- The mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete.

- Consider the following.

- >Slurry Pump

- The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

- Applications of Rubber Lined Slurry Pumps

Latest articles

-

Choosing the right slurry pump

-

The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

-

What is a slurry pump?

-

Fewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - usually 2-5 vanes.

-

What is 'slurry'?

-

Slurry Pump Considerations

Links

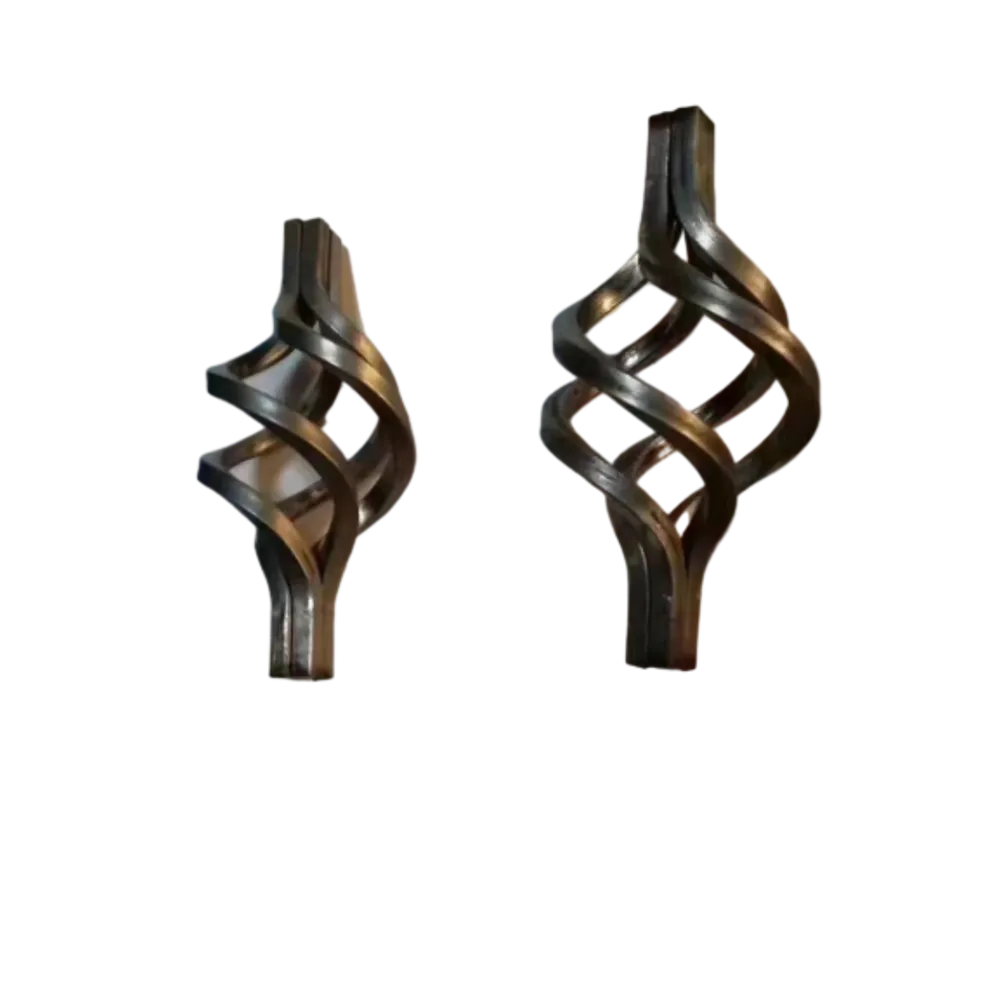

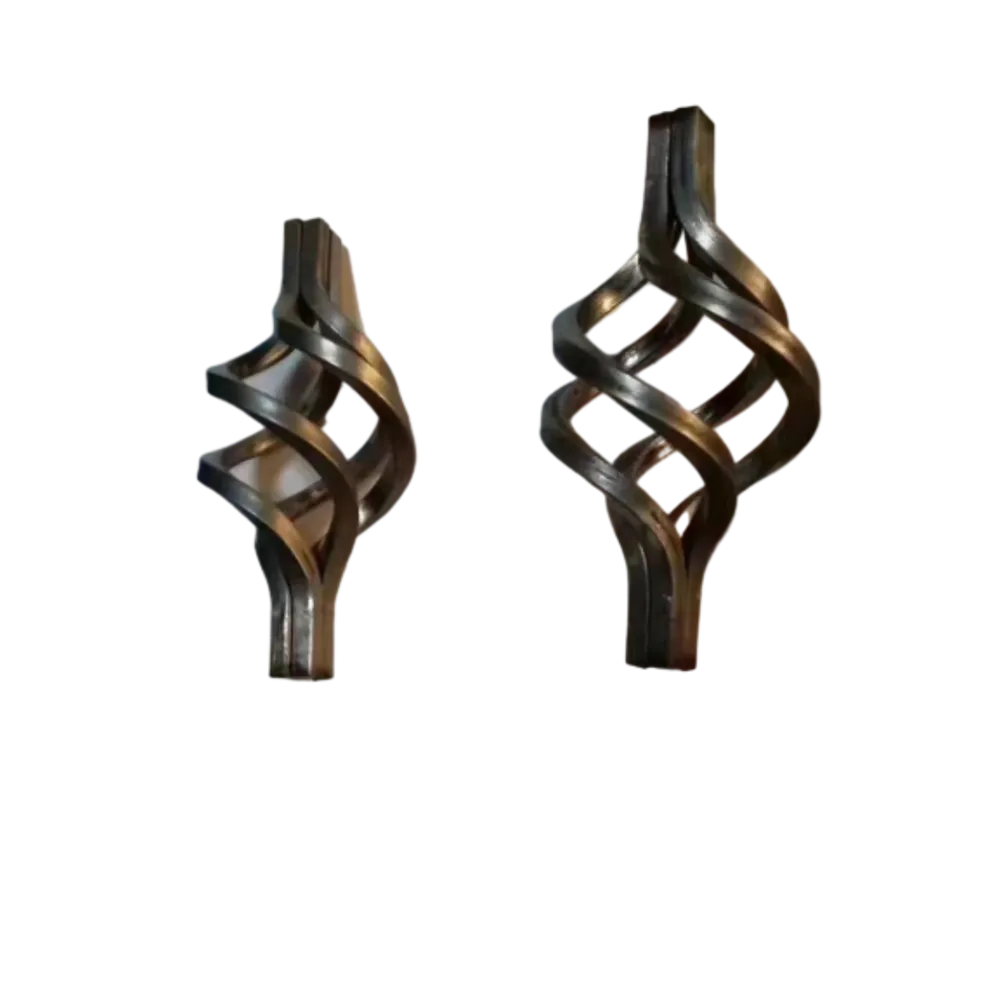

- In contemporary times, wrought iron fence spear points continue to hold a unique appeal. They evoke a sense of nostalgia, connecting us to the rich history of craftsmanship and design. Moreover, they stand as a testament to the enduring appeal of traditional materials and techniques in a world increasingly dominated by modern technologies.

Welcome, all merchants to consult with pictures.

- In conclusion, the concept of cosulet sau bulb cu baza serves as a reminder that there is no one-size-fits-all approach to problem-solving. Sometimes, careful planning and preparation are necessary, while other times quick thinking and adaptability are more important. By being aware of these two approaches and knowing when to use each one, individuals and organizations can improve their ability to navigate the challenges and opportunities that come their way.

- In the world of industrial and commercial applications, the aluminium sliding roller has emerged as a pivotal component, offering unparalleled smoothness and efficiency in movement. These sleek devices are not mere accessories; they are essential tools that facilitate effortless transitions in various settings.

- In conclusion, aluminium sliding door rollers are an essential component of sliding doors and should be replaced promptly when they become worn or damaged. By following the steps outlined above, you can easily replace the rollers and restore the functionality of your sliding door. Remember to choose the right size and type of rollers for your door, and seek professional help if needed. With proper maintenance and care, your aluminium sliding door will continue to provide years of reliable service.

- Furthermore, a large steel lock box is also water-resistant, safeguarding your valuables from water damage in case of a flood or other water-related incident. This feature is particularly beneficial for storing electronics or other items that can be easily damaged by moisture.

Type I Chromic-Acid Anodize

These rollers often include additional features like adjustable height and built-in locks for enhanced security These rollers often include additional features like adjustable height and built-in locks for enhanced security

These rollers often include additional features like adjustable height and built-in locks for enhanced security These rollers often include additional features like adjustable height and built-in locks for enhanced security types of sliding screen door rollers.

types of sliding screen door rollers.Check the available prices for these panels. Galvanized and powder coated. Fully Welded.

Sustainability is also becoming an increasingly important factor in the selection of building materials. Many manufacturers now produce metal door knobs using recycled materials, contributing to eco-friendly building practices. By opting for sustainable metal fixtures, consumers can make environmentally conscious choices without compromising on style or durability.

The cost can be higher upfront, but since you will invest so little in maintenance, the lifetime cost is quite reasonable. Plus, steel fencing can easily be adapted to sloped or uneven land, which is not the case with all fencing materials.

They do not need to be painted or stained, and they can simply be wiped down with a damp cloth to remove dirt and grime They do not need to be painted or stained, and they can simply be wiped down with a damp cloth to remove dirt and grime

They do not need to be painted or stained, and they can simply be wiped down with a damp cloth to remove dirt and grime They do not need to be painted or stained, and they can simply be wiped down with a damp cloth to remove dirt and grime aluminum extrusion profiles for windows and doors. This makes them a cost-effective choice for builders and homeowners alike.

aluminum extrusion profiles for windows and doors. This makes them a cost-effective choice for builders and homeowners alike. This diagnostic phase is critical as it ensures that the correct solution is provided, whether it involves simple roller replacement or more complex track alignments This diagnostic phase is critical as it ensures that the correct solution is provided, whether it involves simple roller replacement or more complex track alignments

This diagnostic phase is critical as it ensures that the correct solution is provided, whether it involves simple roller replacement or more complex track alignments This diagnostic phase is critical as it ensures that the correct solution is provided, whether it involves simple roller replacement or more complex track alignments sliding door roller replacement inc.

sliding door roller replacement inc.Maintenance and Care

Furthermore, you can consider contacting architectural salvage stores that specialize in recycling old building materials. These stores often look for unique or antique wrought iron pieces to offer to their customers.

Rollers for aluminum sliding windows come in various designs, catering to the specific needs and preferences of users. Generally, there are two main types of rollers top-mounted and bottom-mounted.

After installing the new rollers, apply a thin layer of lubricant to both the rollers and the track. This will reduce friction and ensure a smooth glide when operating the screen door. Be careful not to over-lubricate, as excess lubricant can attract dust and dirt, leading to more issues down the line.

Which Features Do You Consider When Buying Aluminum Profile For Windows And Doors?

Common Applications

It can be easily mounted on gates, fences, or walls, providing convenient access to your valuables whenever you need them It can be easily mounted on gates, fences, or walls, providing convenient access to your valuables whenever you need them

It can be easily mounted on gates, fences, or walls, providing convenient access to your valuables whenever you need them It can be easily mounted on gates, fences, or walls, providing convenient access to your valuables whenever you need them stainless steel gate lock box. The box comes with pre-drilled holes for easy installation, and the adjustable mounting brackets allow you to customize the height and angle to suit your specific needs.

stainless steel gate lock box. The box comes with pre-drilled holes for easy installation, and the adjustable mounting brackets allow you to customize the height and angle to suit your specific needs.Pros & Cons of Wrought Iron

The cost can be higher upfront, but since you will invest so little in maintenance, the lifetime cost is quite reasonable. Plus, steel fencing can easily be adapted to sloped or uneven land, which is not the case with all fencing materials.

The bottom line here is that modern aluminium profiles are absolutely no worse insulated than wooden or, even more so, plastic ones. On the contrary, modern aluminium window profiles are distinguished by the best thermal performance and are often used in the construction of passive houses. As a result, the price of aluminium windows and doors has risen considerably in recent years, and we currently have to pay more for them than for wooden windows!