ceramic slurry pump

Latest articles

From an operational point of view the stuffing box is different as it requires some leakage to ensure lubrication and to prevent heat build up. The mechanical seal box should be leak free.

ceramic slurry pump...

ceramic slurry pump 【ceramic slurry pump】

Read MoreExpertise and experience

ceramic slurry pump...

ceramic slurry pump 【ceramic slurry pump】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

ceramic slurry pump...

ceramic slurry pump 【ceramic slurry pump】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

ceramic slurry pump...

ceramic slurry pump 【ceramic slurry pump】

Read MoreSlurry Pump

ceramic slurry pump...

ceramic slurry pump 【ceramic slurry pump】

Read MoreWhat is slurry?

ceramic slurry pump...

ceramic slurry pump 【ceramic slurry pump】

Read MoreSelecting And Operating A Slurry Pump

ceramic slurry pump...

ceramic slurry pump 【ceramic slurry pump】

Read MoreVertical Slurry Pump

ceramic slurry pump...

ceramic slurry pump 【ceramic slurry pump】

Read MoreSlurry Pump

ceramic slurry pump...

ceramic slurry pump 【ceramic slurry pump】

Read MoreThe most important thing here is to determine the pump power required to deliver a specific fluid flow at the desired or required differential pressure. Consider the following.

ceramic slurry pump...

ceramic slurry pump 【ceramic slurry pump】

Read More

Popular articles

- >Dredge Pump

- Applications

- - Portable and low maintenance - There are no long or exposed mechanical shafts between the motor and worm gear, which makes the submersible pump more portable. In addition, because there are no long or exposed mechanical connections between the motor and worm gear, less maintenance is required and operating costs are significantly lower.

- What is a slurry pump?

- Submersible Slurry Pump

- The size and nature of the solids in the liquid: The size and nature will affect the amount of physical wear on the pump and its components, and whether the solids will pass through the pump without being damaged.

Latest articles

-

WZ series slurry pumps are new type wear resistant & corrosion resistant slurry pump for the complexity and specificity of coal, power plant, metallurgy, chemical, building materials and other industries.

-

Mill sump

-

What is slurry?

-

There are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

-

As described below, there are several >types of pumps that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

-

- Smaller, more efficient tank - Because the motor is cooled by the surrounding liquid, the submersible slurry pump can be started up to 30 times per hour, resulting in a smaller, more efficient tank.

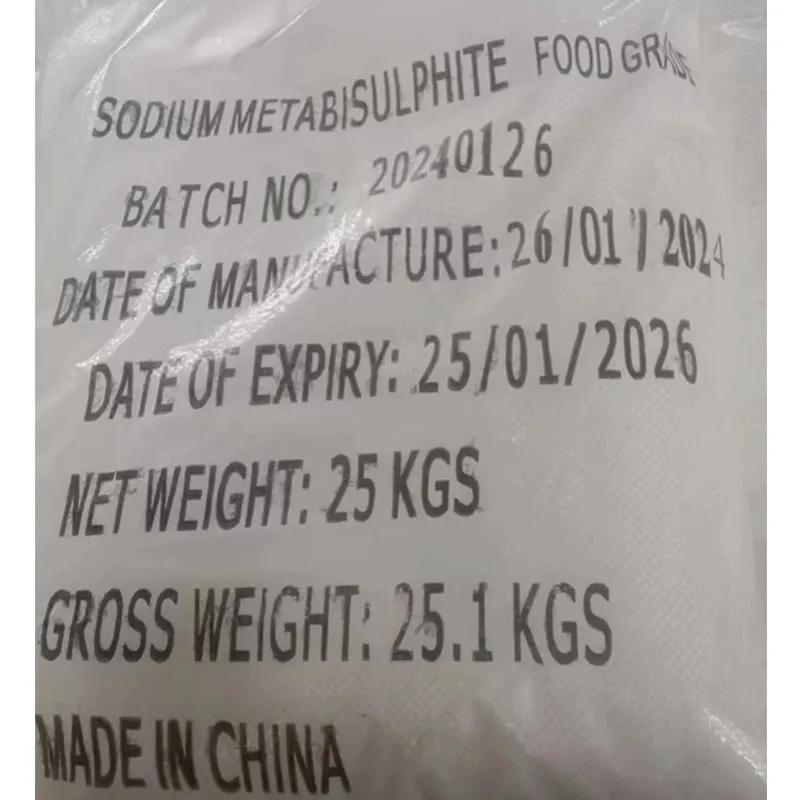

anti caking agents food additives

What is E504?

Another remarkable flavor enhancer is five-spice powder. This aromatic blend usually includes star anise, cloves, Chinese cinnamon, Sichuan peppercorns, and fennel seeds. Its warm, pungent aroma adds depth and complexity to meats, marinades, and stews. The five-spice powder exemplifies the Chinese philosophy of balancing flavors, allowing a harmonious blend of sweet, sour, bitter, and salty notes in a single dish.

Sulfate fertilizers, such as ammonium sulfate and potassium sulfate, are another popular choice among farmers. These fertilizers provide immediate availability of sulfur to plants while also contributing additional nutrients like nitrogen and potassium. The choice of fertilizer often depends on the specific nutrient requirements of the crops being cultivated as well as soil composition and pH levels.

sulfur fertilizer

Polysorbates, such as polysorbate 80, are synthetic emulsifiers that are widely used in the food industry due to their versatility. They are particularly effective in creating stable emulsions and are commonly found in ice creams, sauces, and dressings. Polysorbates help to maintain the dispersion of fat molecules in aqueous solutions, preventing the undesirable separation that can occur in products with high-fat content. Their effectiveness at stabilizing emulsions is often exploited in the production of low-fat and reduced-calorie food products as well.

Beyond its role in improving texture, E1400 also plays a part in enhancing the overall quality of food products. Its ability to absorb water makes it useful in controlling moisture levels, which is crucial for maintaining the freshness and appeal of various items. Furthermore, E1400 is known for its ability to stabilize emulsions, making it an essential component in salad dressings and mayonnaise, where oil and water need to be effectively combined.

Sodium benzoate functions by disrupting the metabolism of microorganisms. Once it is absorbed by fungi or bacteria, it reduces their ability to reproduce by inhibiting certain enzymes. Particularly effective against yeast and certain molds, sodium benzoate works best in acidic environments, with an optimal pH range of 4 to 5. This characteristic makes it especially suitable for products like shampoos, conditioners, and lotions that are formulated at similar pH levels.

The use of sodium acid pyrophosphate in food products has been approved by various food safety authorities, including the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These organizations have deemed it safe for consumption when used in appropriate amounts. However, like many food additives, there are some health considerations to be aware of.

At its core, ammonium bicarbonate is a leavening agent that releases carbon dioxide gas when heated. This gas forms bubbles within the dough or batter, causing it to rise and become lighter and more porous. This reaction occurs at relatively low temperatures, making it particularly well-suited for products that are baked at high temperatures, such as biscuits. The release of gas also contributes to the lightness and crispiness of the final product.

Additionally, natural preservatives are often complemented by innovative packaging solutions. For instance, the use of glass or vacuum-sealed containers can significantly reduce the risk of microbial contamination while minimizing the need for chemical preservatives. Many beverage manufacturers are now adopting an integrated approach, combining natural preservatives with advanced packaging technologies to provide products that meet the increasing consumer demand for quality and sustainability.

Given its varying compositions, businesses in the wholesale market must carefully choose which type of denatured alcohol to stock based on their customer needs and regulatory guidelines

.– in dietary foods for special medical purposes, liquid dietary supplements;

One of the primary functions of natural stabilizers is to enhance the texture and mouthfeel of food products. They help to prevent the separation of ingredients, ensuring a uniform consistency. For example, in salad dressings and sauces, stabilizers like xanthan gum and guar gum create a creamy, smooth texture while preventing the oil and vinegar from separating. This not only improves the sensory experience for consumers but also extends the product's shelf life, which is a significant consideration for manufacturers.

Environmental Considerations

Conclusion

Understanding Sweeteners A Deep Dive into E950, E951, and E955

Gelatin is a natural protein that is soluble in hot water and forms a gel-like consistency upon cooling. Its unique amino acid composition, primarily consisting of glycine and proline, contributes to its gelling properties. Gelatin's ability to form stable gels is primarily due to its capacity to create hydrogen bonds and hydrophobic interactions. When it comes to emulsification, gelatin acts by reducing the surface tension between oil and water phases, allowing for better dispersion and stabilization of emulsions.

One of the most significant benefits of E392 is its ability to act as a natural preservative. In a world where consumers are increasingly demanding clean labels and natural ingredients, tocopherols provide a viable alternative to synthetic preservatives. Unlike some synthetic preservatives that may raise health concerns, tocopherols have been recognized for their safety and are generally well-tolerated by most individuals.

e392 food additive

Sodium Citrate An Essential Food Additive

Bone meal is a slow-release organic fertilizer made from crushed animal bones, primarily cattle bones. It is an excellent source of phosphorus and calcium, which are essential for root development and flowering. Bone meal is particularly beneficial for flowering plants and is commonly used in vegetable gardens to promote healthy growth of root crops such as potatoes and carrots. Its slow-release nature ensures that nutrients are available for an extended period.

Chemistry of Potassium Sorbate

Conclusion

The production of polybutadiene rubber involves the polymerization of 1,3-butadiene, which can be achieved through various methods, including anionic, radical, and coordination polymerization. The most common industrial process is anionic polymerization, typically conducted in an organic solvent at low temperatures, which allows for greater control over the molecular weight and structure of the resultant polymer.

poly butadiene rubber

Despite its many advantages, the use of acetic acid as a preservative is not without limitations. The concentration of acetic acid must be carefully managed to avoid inadvertently altering the taste or texture of the food products. Excessive acidity can lead to undesirable flavors or changes in food quality. It is also worth noting that some consumers may be sensitive to acidity, thereby limiting the applicability of acetic acid-based preservatives in certain markets.

Furthermore, while xanthan gum is derived from the fermentation of sugars, the source sugars can vary. For individuals with certain food allergies or intolerances, it is essential to ensure that the xanthan gum utilized in any product does not originate from their allergenic sources.