high quality warman slurry pump parts

Latest articles

>Slurry Pump vs Mud Pump

high quality warman slurry pump parts...

high quality warman slurry pump parts 【high quality warman slurry pump parts】

Read MoreFrom an operational point of view the stuffing box is different as it requires some leakage to ensure lubrication and to prevent heat build up. The mechanical seal box should be leak free.

high quality warman slurry pump parts...

high quality warman slurry pump parts 【high quality warman slurry pump parts】

Read MoreVertical Slurry Pump

high quality warman slurry pump parts...

high quality warman slurry pump parts 【high quality warman slurry pump parts】

Read MoreSlurry Pump

high quality warman slurry pump parts...

high quality warman slurry pump parts 【high quality warman slurry pump parts】

Read MoreThe basic mechanical seal flushing programme is very simple. It requires that a clear/clean fluid (usually water) is introduced into the space between the actual seal and the impeller side outlet restriction. The flushing fluid is introduced at a pressure higher than the pumping pressure, thus ensuring positive outflow/flushing of the mechanical seal and a clean operating environment.

high quality warman slurry pump parts...

high quality warman slurry pump parts 【high quality warman slurry pump parts】

Read MoreThese conditions include

high quality warman slurry pump parts...

high quality warman slurry pump parts 【high quality warman slurry pump parts】

Read MoreWhat style of pump is suitable?

high quality warman slurry pump parts...

high quality warman slurry pump parts 【high quality warman slurry pump parts】

Read MoreOne of the most frequently asked questions from our team of pump experts is: How do I pump slurry?xa0With this in mind, our team of experts have provided a useful guide to pumping slurry.

high quality warman slurry pump parts...

high quality warman slurry pump parts 【high quality warman slurry pump parts】

Read Morehow-does-a-dredge-pump-work

high quality warman slurry pump parts...

high quality warman slurry pump parts 【high quality warman slurry pump parts】

Read MoreFewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - usually 2-5 vanes.

high quality warman slurry pump parts...

high quality warman slurry pump parts 【high quality warman slurry pump parts】

Read More

Popular articles

- How Slurry Pumps Differ From Standard Pumps?

- >Slurry Pump vs Mud Pump

- Another way of classifying the type of slurry pump installation is dry installation or wet installation. Dry installation pumps have the hydraulic end and drive located outside the liquid, whereas wet installation pumps (such as submersible pumps) operate within a catch basin or slurry. Submersible pumps do not require much support structure and therefore do not take up much space. Depending on the type of operation and installation required, the preferred method of pump installation is determined.

- Slurry Pump

- Consider the impeller. Slurry pumps must have thicker vanes than water pumps to prevent wear. Due to the increased thickness, there will be fewer vanes, otherwise the passages will be too narrow and will affect the performance of the pump. The impeller should have a large enough passage so that the largest solid particles can pass through without clogging.

- >Slurry Pump

Latest articles

-

Typically, slurries are.

-

Includes a large number of solids or particles.

-

The Company Adopts Advanced Computer Aided Engineering Software

-

What is slurry?

-

WA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

-

factors-to-consider-when-choosing-a-slurry-pump

Links

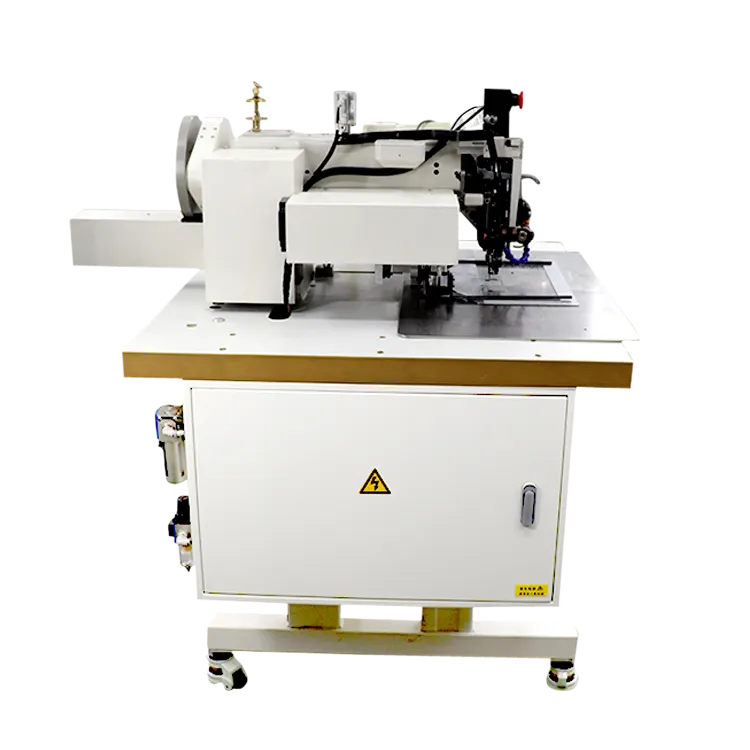

5. Feed System An efficient feed system is essential for sewing different types of fabric smoothly. Look for machines with adjustable presser feet and multiple feed dog configurations.

In conclusion, the walking foot sewing machine is an indispensable tool for anyone serious about sewing. Its unique feeding mechanism offers unparalleled control and precision, making it ideal for a wide variety of fabrics and sewing applications. By understanding its capabilities and properly maintaining it, sewists can unlock the full potential of their walking foot sewing machines, resulting in beautifully crafted projects that reflect their skills and creativity. Whether you are a seasoned professional or a sewing enthusiast, embracing this machine can elevate your sewing experience to new heights.

Furthermore, these machines come equipped with various features such as adjustable stitch lengths, automatic thread tension control, and built-in needle threaders, simplifying the sewing process and minimizing errors Furthermore, these machines come equipped with various features such as adjustable stitch lengths, automatic thread tension control, and built-in needle threaders, simplifying the sewing process and minimizing errors

Furthermore, these machines come equipped with various features such as adjustable stitch lengths, automatic thread tension control, and built-in needle threaders, simplifying the sewing process and minimizing errors Furthermore, these machines come equipped with various features such as adjustable stitch lengths, automatic thread tension control, and built-in needle threaders, simplifying the sewing process and minimizing errors