slurry sand pump manufacturer

Latest articles

>Dredge Pump

slurry sand pump manufacturer...

slurry sand pump manufacturer 【slurry sand pump manufacturer】

Read MoreThe solution is to choose a >heavy duty slurry pump and, just as importantly, to use a custom built unit with replaceable parts. At Aier Machinery, building your custom slurry pump is one of our areas of expertise. We design your slurry pump to your specifications and application.

slurry sand pump manufacturer...

slurry sand pump manufacturer 【slurry sand pump manufacturer】

Read MoreSlurry pump construction materials

slurry sand pump manufacturer...

slurry sand pump manufacturer 【slurry sand pump manufacturer】

Read MoreA typical pump solution for this application is to install a hard metal >slurry pump to withstand these types of conditions. Hard metal pumps need to be able to withstand the most severe abrasive slurry service and they also need to be designed to be extremely easy to maintain and safe.

slurry sand pump manufacturer...

slurry sand pump manufacturer 【slurry sand pump manufacturer】

Read MoreAgain, to meet life cycle cost considerations, pumps should be equipped with large diameter impellers for lower operating speeds and longer wear life, as well as field replaceable rubber liners that can be bolted on for quick maintenance. In a typical coal-fired power plant, two to five pumps will be used in each spray tower.

slurry sand pump manufacturer...

slurry sand pump manufacturer 【slurry sand pump manufacturer】

Read MoreHow much solids damage can the customer tolerate?

slurry sand pump manufacturer...

slurry sand pump manufacturer 【slurry sand pump manufacturer】

Read MoreWhat is a dredging pump?

slurry sand pump manufacturer...

slurry sand pump manufacturer 【slurry sand pump manufacturer】

Read MoreMechanical Seals

slurry sand pump manufacturer...

slurry sand pump manufacturer 【slurry sand pump manufacturer】

Read MoreIs the discharge configuration suitable for abrasive slurries?

slurry sand pump manufacturer...

slurry sand pump manufacturer 【slurry sand pump manufacturer】

Read MoreIt is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

slurry sand pump manufacturer...

slurry sand pump manufacturer 【slurry sand pump manufacturer】

Read More

Popular articles

- Larger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

- As this limestone slurry needs to be moved efficiently through a complex industrial process, the selection of the right pumps and valves (taking into account their whole life cycle costs and maintenance) is crucial.

- Vertical Slurry Pumps Pump Sewage More Efficiently

- Dredge pumps are designed to transfer large quantities of fluids and solids.

- Slurry Pump Speed

- 2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

Latest articles

-

600WN to 1000WN dredge pumps are of double casings, single stage cantilevered centrifugal pumps. These pumps are equipped with frame and lubrication is force thin oil. The design of double casing the pump working till the volute liner almost worn down and guarantee no leakage when volute liner is worn down.

-

Although the focus of slurry pumps is often on the size and percentage of solids to be pumped, in many applications corrosion resistance is also an important factor in material selection. In such cases, the material chosen must provide adequate resistance to erosion and corrosion.

-

Depending on the abrasive nature of the slurry, it is important to select the ideal seal. Slurry pump seals should have a hardened surface made of silicon carbide or tungsten carbide. Vortex pumps use patented seal technology that utilizes a double mechanical seal setup and a separate seal flushing system. This allows the sealing surface to be kept cool at all times without causing the slurry to overheat the seal and crack the surface.

-

A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

-

To reduce wear, reduce the pump discharge pressure to the lowest possible point.

-

The size and nature of the solids in the liquid: The size and nature will affect the amount of physical wear on the pump and its components, and whether the solids will pass through the pump without being damaged.

Links

Features - A double-sided cast iron griddle is essentially a large, flat pan with cooking surfaces on both sides. One side typically features a smooth surface ideal for pancakes, eggs, and delicate foods, while the other may have ridges perfect for searing steaks, grilling vegetables, or making crispy bacon. This unique design doubles the cooking possibilities, making it an indispensable tool for both amateur chefs and professional cooks.

- In addition to their exceptional cooking properties, high-end cast iron skillets are also extremely durable. With proper care and maintenance, these skillets can last for generations, making them a great investment for any kitchen. Unlike non-stick pans that can wear out and lose their coating over time, cast iron skillets only get better with age as they develop a natural seasoning that enhances the flavor of food.

- 2. Calphalon Premier Space-Saving Hard-Anodized Nonstick 8-Inch Fry Pan This pan from Calphalon is another great option for those who want a lightweight frying pan with excellent performance. It features a hard-anodized construction that provides even heat distribution and durability.

Enamel Cookware Maintenance

Ceramic pans are also light in weight and cannot be subjected to high heat. They shouldn't be used with metallic utensils and can only be used on a stovetop.

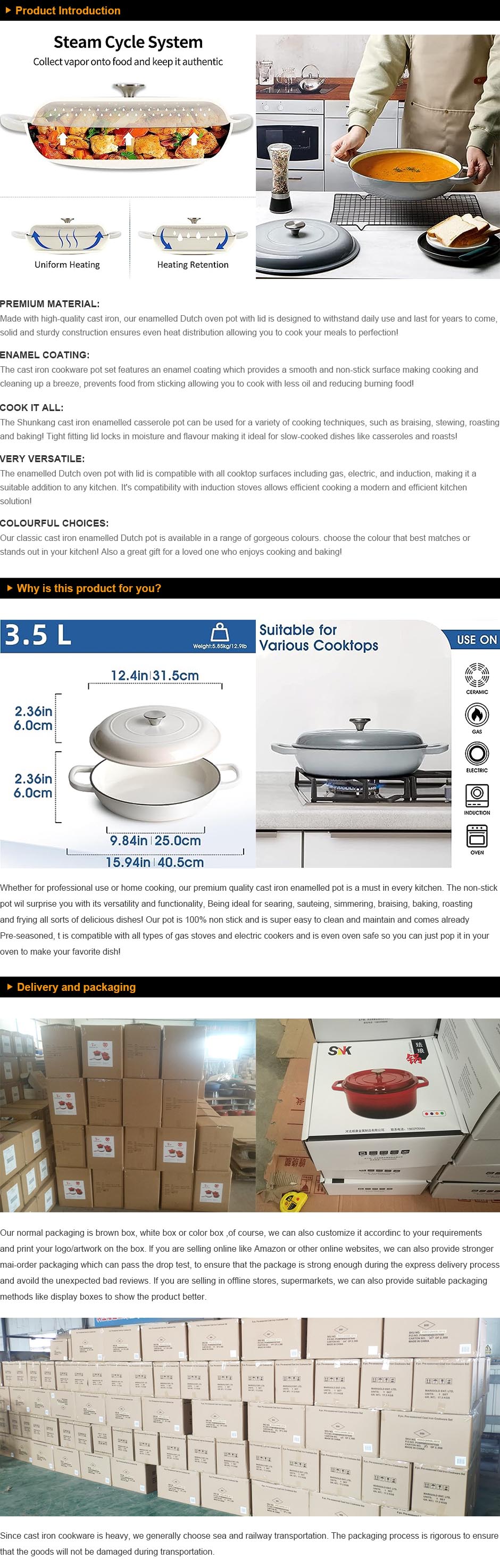

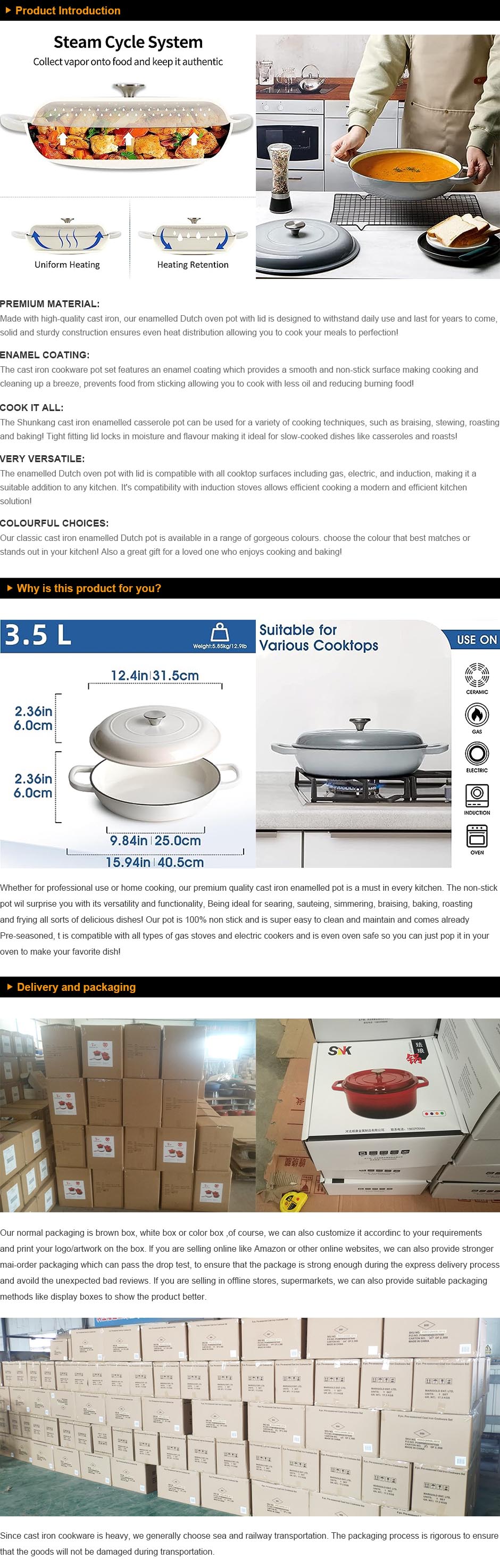

dutch oven 9qt. Whether you're searing meat on the stove before braising in the oven or baking a homemade loaf of bread, this oven provides a convenient one-pot solution. Its sturdy handle design allows for safe and secure handling, even when filled to the brim.

dutch oven 9qt. Whether you're searing meat on the stove before braising in the oven or baking a homemade loaf of bread, this oven provides a convenient one-pot solution. Its sturdy handle design allows for safe and secure handling, even when filled to the brim.

Its portable nature makes it perfect for outdoor cooking, camping trips, or even picnics Its portable nature makes it perfect for outdoor cooking, camping trips, or even picnics

Its portable nature makes it perfect for outdoor cooking, camping trips, or even picnics Its portable nature makes it perfect for outdoor cooking, camping trips, or even picnics sizzling hot plate for sale. Imagine the convenience of having a reliable cooking source at your fingertips, regardless of where your culinary adventures take you.

sizzling hot plate for sale. Imagine the convenience of having a reliable cooking source at your fingertips, regardless of where your culinary adventures take you.Made from: iron, which heats slowly but evenly and stays scorching hot

The two can be used interchangeably for grilling, roasting, stewing, and frying. There is no distinction between the two when it comes to cooking. A frying pan, for example, can be used in place of a skillet and vice versa.

Before using your bacon press, ensure that your cooking surface, whether it be a skillet, griddle, or grill, is preheated to the desired temperature. Proper preheating helps to achieve an even cook and crispiness.

Clean Enamel Cookware

The Indus Valley has mixed the goodness of both stainless steel and aluminium and is presenting Tri-ply Stainless Steel Cookware.

This revolutionary series has a layer of aluminium core sandwiched between two layers of stainless steel, which allows for perfectly even heating.

Long-Lasting: When properly cared for, enamel cookware, including potjie pots, can last for generations, making it a timeless and enduring addition to any kitchen.

Interactive Presentation: The sizzle and steam emanating from the hot plate or platter create an interactive and sensory dining experience, engaging diners and adding an element of excitement to the meal presentation.

It's also perfect for making international favorites like crepes, dosas, or even Korean BBQ-style meals It's also perfect for making international favorites like crepes, dosas, or even Korean BBQ-style meals

It's also perfect for making international favorites like crepes, dosas, or even Korean BBQ-style meals It's also perfect for making international favorites like crepes, dosas, or even Korean BBQ-style meals two sided griddle.

two sided griddle.The difference between a sauté pan and a skillet is a subtle but important one, and it all comes down to shape. A sauté pan, from the French verb meaning to jump (sauter), has a wide, flat bottom and relatively tall, vertical sides. A skillet, on the other hand, has sides that flare outward at an angle. But the real question is, when should you use each one, and do you really need both?

When choosing a Dutch oven, it is important to consider the type of cooking you will be doing and the size of the meals you will be preparing. Whether you choose a large cast iron Dutch oven or a small cast iron Dutch oven, each type has its own unique advantages and can be a valuable addition to your kitchen arsenal. With the right Dutch oven, you can take your cooking to the next level and create delicious, delicious meals with ease.

They remind us of the virtues of slowing down, taking the time to prepare meals with love, and savoring the experience of cooking as much as the food itself They remind us of the virtues of slowing down, taking the time to prepare meals with love, and savoring the experience of cooking as much as the food itself

They remind us of the virtues of slowing down, taking the time to prepare meals with love, and savoring the experience of cooking as much as the food itself They remind us of the virtues of slowing down, taking the time to prepare meals with love, and savoring the experience of cooking as much as the food itself cast iron cookware company.

cast iron cookware company.