vertical float sump pump supplier

Latest articles

If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

vertical float sump pump supplier...

vertical float sump pump supplier 【vertical float sump pump supplier】

Read MoreDredge pumps are designed to transfer large quantities of fluids and solids.

vertical float sump pump supplier...

vertical float sump pump supplier 【vertical float sump pump supplier】

Read MoreChoosing Dry Slurry Pumps Versus Submersible Slurry Pumps

vertical float sump pump supplier...

vertical float sump pump supplier 【vertical float sump pump supplier】

Read MoreIn dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

vertical float sump pump supplier...

vertical float sump pump supplier 【vertical float sump pump supplier】

Read MoreWZ series slurry pumps are developed on the wide adaption of both home and abroad advance technology and many years of slurry pump design and field operation experiences.

vertical float sump pump supplier...

vertical float sump pump supplier 【vertical float sump pump supplier】

Read MoreWhat is the best seal arrangement for the application?

vertical float sump pump supplier...

vertical float sump pump supplier 【vertical float sump pump supplier】

Read MoreHow does a dredge pump work?

vertical float sump pump supplier...

vertical float sump pump supplier 【vertical float sump pump supplier】

Read MoreLonger maintenance intervals

vertical float sump pump supplier...

vertical float sump pump supplier 【vertical float sump pump supplier】

Read MoreCustomised pumps

vertical float sump pump supplier...

vertical float sump pump supplier 【vertical float sump pump supplier】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

vertical float sump pump supplier...

vertical float sump pump supplier 【vertical float sump pump supplier】

Read More

Popular articles

- 2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

- Slurry Pump Considerations

- Slurry pump construction materials

- The frame plate for WAJ series pumps has interchangeable hard metal or pressure moulded elastomer liners. The impellers are made of pressure moulded elastomer liners.The shaft seals for WAJ series can be packing seal, centrifugal seal or mechanical seal.

- Choosing the right material for a slurry pump is another key process in determining the right pump for handling slurry. If the slurry is highly abrasive with neutral pH, then the best material of construction is Hi-Chrome. this metallurgy has the highest Brinell hardness and can withstand the abrasiveness of the slurry.

- A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right >pump. In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

Latest articles

-

The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of , submersible slurry pump, versus dry mount pumping and shares some general rules that apply to both applications.xa0Next, the , slurry pump manufacturer, xa0 will share the following content with you.

-

Step 3

-

1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

-

>Slurry Pump

-

If you've ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. There's no doubt that the slurry on the pump is hard. But the more you know about what's being pumped, the better your pump selection will be, resulting in longer mean time between failures. Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share the following content with you.

-

It is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

A lower price tag does not always equate to a lower standard of quality A lower price tag does not always equate to a lower standard of quality

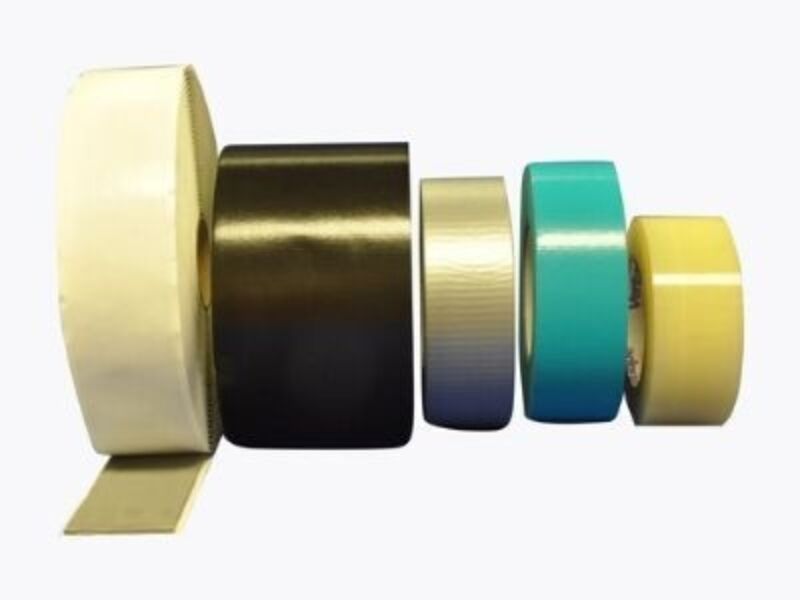

A lower price tag does not always equate to a lower standard of quality A lower price tag does not always equate to a lower standard of quality wholesale price pvc tape electrical insulation. Reputable suppliers will provide consistent performance across their products, ensuring that each roll meets industry standards for electrical insulation.

wholesale price pvc tape electrical insulation. Reputable suppliers will provide consistent performance across their products, ensuring that each roll meets industry standards for electrical insulation. Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets

Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets diall self amalgamating tape. Celebrating minor victories along the way is essential, similar to acknowledging the successful mends made by the tape.

diall self amalgamating tape. Celebrating minor victories along the way is essential, similar to acknowledging the successful mends made by the tape.Overlap Layers: For added strength, consider overlapping multiple layers of tape. This is particularly important in high-pressure or high-temperature applications.

Benefits of Using Black PVC Electrical Tape

This tape comes in eight colors:

Electrical tape is designed to provide a secure bond but is easily removable and residue free. Duct tape is exceptionally sticky due to its adhesive composition. The rubber-based adhesive allows duct tape to bond with various surfaces for long periods of time. Because of its extreme stickiness, residue sometimes is left behind.

In fact, PVC has a very high ignition temperature, meaning it takes a lot of heat to actually set it on fire.

Selecting the right tape for motor connections

7. Easy to use: a layer of Self Fusing tape can play a good insulation role and reduce labor and cost.

Durability High temperature insulation tape is resistant to wear and tear, fading, and discoloration, ensuring long-lasting performance Durability High temperature insulation tape is resistant to wear and tear, fading, and discoloration, ensuring long-lasting performance

Durability High temperature insulation tape is resistant to wear and tear, fading, and discoloration, ensuring long-lasting performance Durability High temperature insulation tape is resistant to wear and tear, fading, and discoloration, ensuring long-lasting performance high temperature insulation tape.

high temperature insulation tape. Its self-adhesive nature ensures a strong bond instantly, eliminating the need for additional adhesives or curing processes Its self-adhesive nature ensures a strong bond instantly, eliminating the need for additional adhesives or curing processes

Its self-adhesive nature ensures a strong bond instantly, eliminating the need for additional adhesives or curing processes Its self-adhesive nature ensures a strong bond instantly, eliminating the need for additional adhesives or curing processes 130c linerless rubber splicing tape. This not only streamlines production but also enhances productivity.

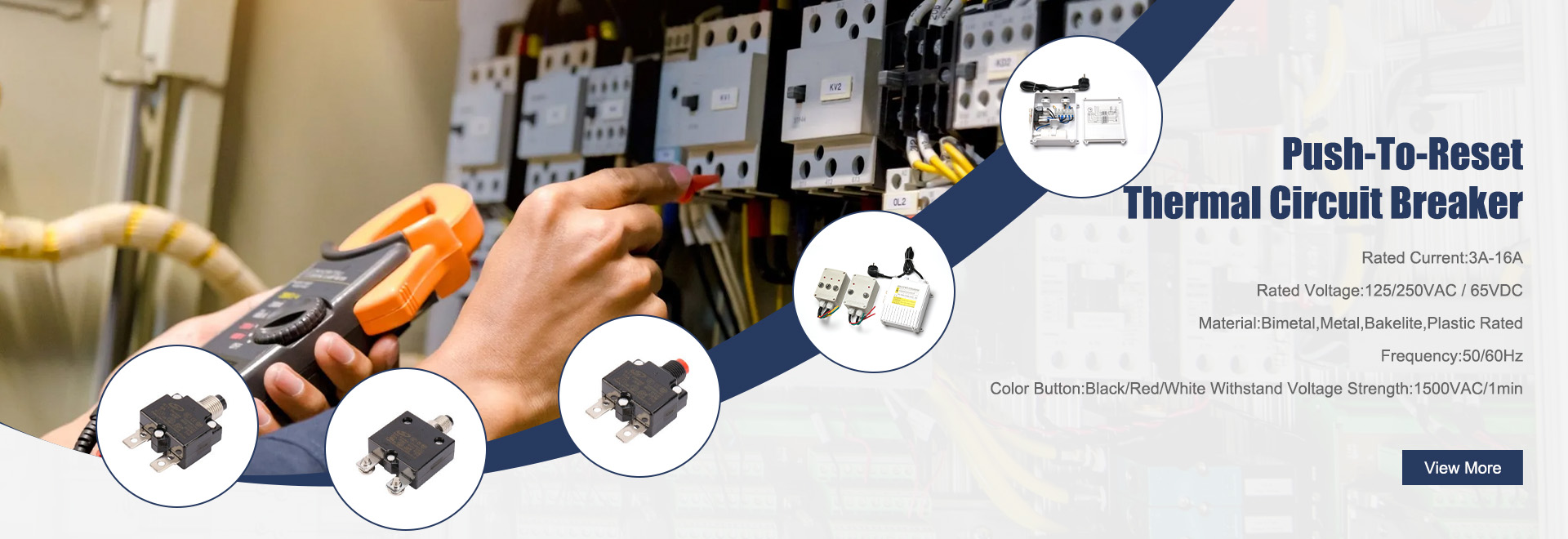

130c linerless rubber splicing tape. This not only streamlines production but also enhances productivity.The well pumps that provide water to private well systems are another area in which you’ll frequently find control boxes. Typically, these designs are relatively simple—but, like all control boxes, they serve a critically important purpose.

You can also find many more in-depth studies of what makes a good control box online. They’ll help you get a good idea of how to design component spacing, wireways and more. Next up, we’ll take a look at what some of the different types of control boxes look like and how they function.

The processing unit is the component that allows you to feed commands into your control box and monitor its performance or status. Most control boxes utilize microcontrollers or PLCs, which are capable of fulfilling complex functions. For instance, they can interpret your predefined algorithms and command your system to execute them.

Heat tape, commonly referred to as heat trace or heat trace tape, is an essential heating solution in various electric applications. This flexible electrical tape is designed to provide consistent heat to pipes, roofs, and other structures to prevent freezing, moisture buildup, or maintain required temperatures. As the demand for efficient temperature management grows, heat tape has emerged as a popular choice across numerous industries and households.

non flammable tape.