high quality horizontal froth pump factories

Latest articles

Under ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

high quality horizontal froth pump factories...

high quality horizontal froth pump factories 【high quality horizontal froth pump factories】

Read MoreFor example.

high quality horizontal froth pump factories...

high quality horizontal froth pump factories 【high quality horizontal froth pump factories】

Read MoreIncludes a large number of solids or particles.

high quality horizontal froth pump factories...

high quality horizontal froth pump factories 【high quality horizontal froth pump factories】

Read MoreAny type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

high quality horizontal froth pump factories...

high quality horizontal froth pump factories 【high quality horizontal froth pump factories】

Read MoreWhat style of pump is suitable?

high quality horizontal froth pump factories...

high quality horizontal froth pump factories 【high quality horizontal froth pump factories】

Read MoreRepairable - target=_blank title=Rubber Lined Slurry Pumps>Rubber lined slurry pumps can be repaired by simply replacing the bushing.

high quality horizontal froth pump factories...

high quality horizontal froth pump factories 【high quality horizontal froth pump factories】

Read MoreWhat is a slurry?

high quality horizontal froth pump factories...

high quality horizontal froth pump factories 【high quality horizontal froth pump factories】

Read MoreWhat is a dredging pump?

high quality horizontal froth pump factories...

high quality horizontal froth pump factories 【high quality horizontal froth pump factories】

Read MoreAbrasive.

high quality horizontal froth pump factories...

high quality horizontal froth pump factories 【high quality horizontal froth pump factories】

Read MoreAs this limestone slurry needs to be moved efficiently through a complex industrial process, the selection of the right pumps and valves (taking into account their whole life cycle costs and maintenance) is crucial.

high quality horizontal froth pump factories...

high quality horizontal froth pump factories 【high quality horizontal froth pump factories】

Read More

Popular articles

- What is a slurry?

- A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right >pump. In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

- There is a science behind the design of a , slurry pump, , based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

- How to Succeed in Slurry Pumping?

- >Slurry Pump vs Mud Pump

- Dredge pumps are designed to transfer large quantities of fluids and solids.

Latest articles

-

First, what is a slurry? A slurry is a semi-liquid mixture, usually consisting of fine particles. Examples of slurries can include manure, cement, starch, or coal suspended in water. There are countless other combinations that can be considered slurries. Because of the added particles and thicker consistency, special pump requirements should be considered. A standard pump may be able to handle the fluid, but not as effectively as a properly sized slurry pump.

-

As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

-

Another way of classifying the type of slurry pump installation is dry installation or wet installation. Dry installation pumps have the hydraulic end and drive located outside the liquid, whereas wet installation pumps (such as submersible pumps) operate within a catch basin or slurry. Submersible pumps do not require much support structure and therefore do not take up much space. Depending on the type of operation and installation required, the preferred method of pump installation is determined.

-

Heavy-Duty Slurry Pump

-

What is slurry?

-

I hope this short blog has helped to clear up some of the confusion about the seal flush programme. Please always refer to the pump manual for specific details. If there are still questions, welcome to >contact us today.

How are Cast Iron vs. Wrought Iron Fences Different?

It allows you to understand numerous elements to facilitate your decision-making process when shopping for the most suitable pieces.

If you prefer a more minimalist look, opt for simple cast iron wall art or decorative hooks to add a subtle touch of style to your home. These understated pieces can complement a range of interior design styles, from modern to rustic, and can be easily integrated into existing decor.

Installation Considerations

Cost-Effectiveness

One of the main benefits of a lockable storage box is the security it provides. Outdoor spaces can sometimes be vulnerable to theft, especially when valuable items such as gardening equipment, outdoor games, or tools are left unsecured. A metal storage box with a robust locking mechanism acts as a deterrent to potential thieves, ensuring that your possessions remain safe. Knowing that your items are secured can also give you peace of mind while you're away from home or enjoying time with family and friends.

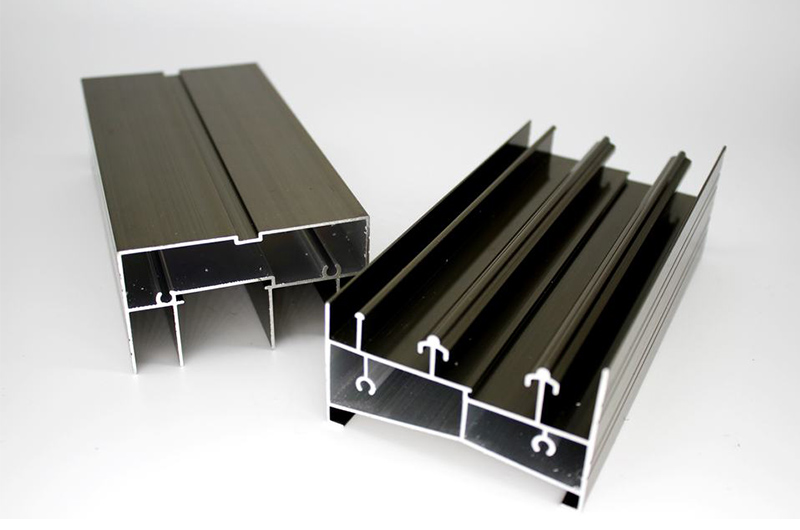

Extrusion: The billet is heated and placed onto an extrusion press, which passes it through a die and goes through several processes to ensure it is straight, strong, and of the required quality. The extrusion process includes an automatic production line composed of ingot heating, extrusion, cooling, straightening, cutting, and other processes .

Plastic Taps Lightweight and Corrosion-Resistant

An aluminium window profile is composed of several components that work together to create a functional and secure window assembly. Here are the main components of an aluminium window profile:

Ornamental iron: It is formed by machinery and then welded into a final shape. You will notice the extreme attention to detail and can see a welded seam down the center of pickets, rails, or posts.

- Inspect for Damage Regularly check the wheels for any signs of wear and tear. If the wheels are cracked or significantly worn down, consider replacing them to prevent further issues.

Functionality and Convenience

In other words, the actual cost of your ideal aluminum profiles for windows and doors is dependent on numerous factors, including the aforementioned ones.

Knowledge of installation:

Typical aluminum material for windows and doors profiles is often taken through aging process during extrusion. The process strengthens the material, and as temperature reduces, its strength increases.