china building dredge pump factory

Latest articles

Step 4

china building dredge pump factory...

china building dredge pump factory 【china building dredge pump factory】

Read MoreSlurry Pump

china building dredge pump factory...

china building dredge pump factory 【china building dredge pump factory】

Read MoreThe concentration of solids in the slurry - measured as a percentage of the total volume.

china building dredge pump factory...

china building dredge pump factory 【china building dredge pump factory】

Read MoreCorrosiveness of the slurry

china building dredge pump factory...

china building dredge pump factory 【china building dredge pump factory】

Read MoreSome quench seals are planned to replace the tight fitting outlet restriction with a secondary seal and a top outlet that can be piped to capture the used quench fluid and drain it from the rotating assembly. However the principle is the same, we try to cool the seal rather than flush it in any way.

china building dredge pump factory...

china building dredge pump factory 【china building dredge pump factory】

Read MoreSubmersible Slurry Pump

china building dredge pump factory...

china building dredge pump factory 【china building dredge pump factory】

Read MoreThe slurry pump is mainly used in the mining industry, its wear resistance is strong. So It conveys slurry that containing slag, but it can conveys mud. The mud pump is usually made of cast iron, the wear resistance of the pump is low. So the mud pumps often used for conveying mud or slurry containing suspended particles.

china building dredge pump factory...

china building dredge pump factory 【china building dredge pump factory】

Read MoreSlurry Pump

china building dredge pump factory...

china building dredge pump factory 【china building dredge pump factory】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

china building dredge pump factory...

china building dredge pump factory 【china building dredge pump factory】

Read MoreSites often rely on centrifugal pumps to provide slurry service. These pumps (and their associated piping systems) require special provisions that demand detailed knowledge of the properties of solids and slurries to prevent wear, corrosion, erosion and other adverse effects such as solids settling. Specifying the optimum combination of speed, geometry and material requires a proper balance of often conflicting pump priorities; this requires consideration of stable operation, maximum wear life, operational flexibility and minimum energy consumption.

china building dredge pump factory...

china building dredge pump factory 【china building dredge pump factory】

Read More

Popular articles

- Mechanical Seals

- - Pumping the final product in a process

- Submersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

- Series of TL >FGD pump is a single stage single suction horizontal centrifugal pump. It is mainly used as the circulation pump for absorbent tower in FGD applications. It has such features: wide range flowing capacity, high efficiency, high saving power. This series of pump is matched by tight structure X bracket which can save much space. Meanwhile our company develops many kinds of material targeted on the pumps for FGD.

- There are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

- There are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

Latest articles

-

With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

-

>Slurry pumps are typically larger than standard pumps, with more horsepower and stronger bearings and shafts. The most common type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids move through a standard centrifugal pump.

-

One of the most frequently asked questions from our team of pump experts is: How do I pump slurry?xa0With this in mind, our team of experts have provided a useful guide to pumping slurry.

-

Consider the pump components

-

Safety

-

Why would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

Links

In addition to these popular models, there are many other sewing machine specials currently available that cater to a wide range of preferences and budgets. From basic mechanical machines to advanced computerized models, there is a sewing machine special for every need and skill level. And with discounts and deals that make these machines more affordable than ever, now is the perfect time to invest in a new sewing machine and take your sewing projects to the next level.

One of the biggest attractions of heavy-duty machines is that they are made from thicker, stronger materials. This means that they will be able more durable than a regular machine. This is because it was designed to be used more frequently. For example, heavy-duty machines tend to contain a larger engine. This means that it will be able to provide more power, and will be better suited to longer sewing sessions.

- Project Scope Assess the types of upholstery projects you will be undertaking. If you work primarily with heavy materials, ensure that the machine you choose is specifically designed for such applications.

2. Adjust Tension Depending on your fabric, you might need to adjust the tension settings. A typical tension range is between 4 and 6. Perform a test stitch on a scrap piece of fabric before starting on your actual project. Adjust the tension as needed until the stitches lay flat and evenly spaced.

Beyond garments, the double needle stretch stitch can also be employed in crafting projects and upholstery, such as making stretchable pillow covers or creating décor items requiring flexible seams. Its versatility makes it an essential technique for anyone looking to expand their sewing skills.

5. Maintenance Capabilities Given the intensive use of these machines, easy maintenance and access to replacement parts are vital for minimizing downtime and ensuring smooth production workflows.

Lock stitches are used in numerous sewing applications, from garment construction to quilting, due to their structural integrity

. Here are some common useslock stitch on sewing machine

Advantages of the Double Needle Feature

Budget is another important factor. While high-end models can be quite an investment, there are also more affordable options that provide great value without compromising on essential features.

- Purpose Assess what types of projects you plan to create. For heavy-duty items like saddles or upholstery, look for machines that can handle thicker materials.

Key Features

Why Choose Heavy-Duty for Vinyl?

Key Features

Moreover, the single needle lockstitch machine is not only instrumental in the production of ready-to-wear clothing but also plays a significant role in the world of fashion design. Designers frequently use these machines to create prototypes and samples, as the precision of the lockstitch allows for intricate designs and patterns. The ability to make quick alterations and adjustments during the sewing process is invaluable in a field where creativity and adaptability are paramount.

Beyond quilting, raised bed sewing machines are versatile enough to accommodate various sewing projects. They can be used for making curtains, upholstery, and other home décor items that often require large fabric pieces. The extra height and space facilitate sewing multiple layers, which is commonly encountered in projects involving thicker materials. As a result, sewists can tackle a broader range of textiles without worrying about machine limitations.

4. Automatic Functions Advanced models often include automatic features such as thread cutting, needle positioning, and tension adjustments. These functions not only enhance the sewing experience but also improve the quality of the finished project, making it less likely for users to encounter issues like uneven stitching or thread bunching.

One of the defining characteristics of high-speed single needle lockstitch sewing machines is their ability to operate at impressive speeds, often exceeding 5,000 stitches per minute. This capability significantly reduces sewing time, enabling manufacturers to meet tight deadlines and increase output. The precision of these machines ensures that even at high speeds, the quality of the stitching remains consistent, which is crucial in the production of garments where quality control is paramount.

high speed single needle lockstitch sewing machine

Just like any other piece of equipment, a sailmaker sewing machine requires regular maintenance to ensure optimal performance. Sailmakers are advised to clean their machines after each use, lubricating moving parts and checking for any wear on the needles or other components. Regular maintenance prolongs the life of the sewing machine and maintains its ability to produce high-quality stitches.

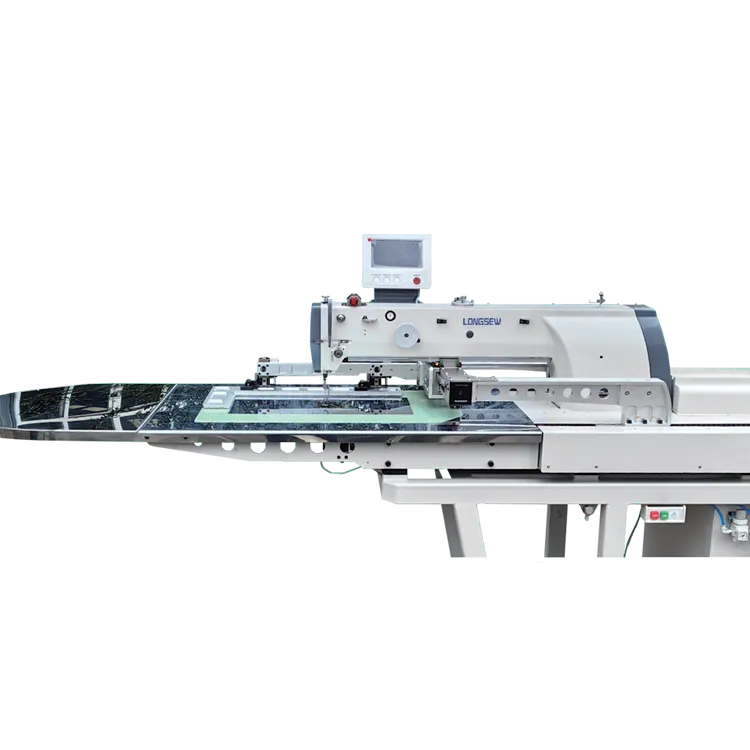

Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020

The commercial zig zag sewing machine is utilized across a multitude of industries. In fashion manufacturing, designers use these machines to create intricate patterns and finish seams, ensuring durability in the garments they produce. In upholstery, the zig zag stitch is vital for reinforcing seams, making furniture covers more resilient. Additionally, for hobbyists and crafters, this machine opens up a world of creative possibilities, allowing for customization and personalization of various projects.

Precision is another hallmark of automatic button sewing machines. The consistent tension and alignment achieved through automation eliminate common issues found in manual sewing, such as crooked buttons or misaligned stitching. This precision is particularly crucial in the fashion industry, where the quality of a garment can significantly affect its marketability.

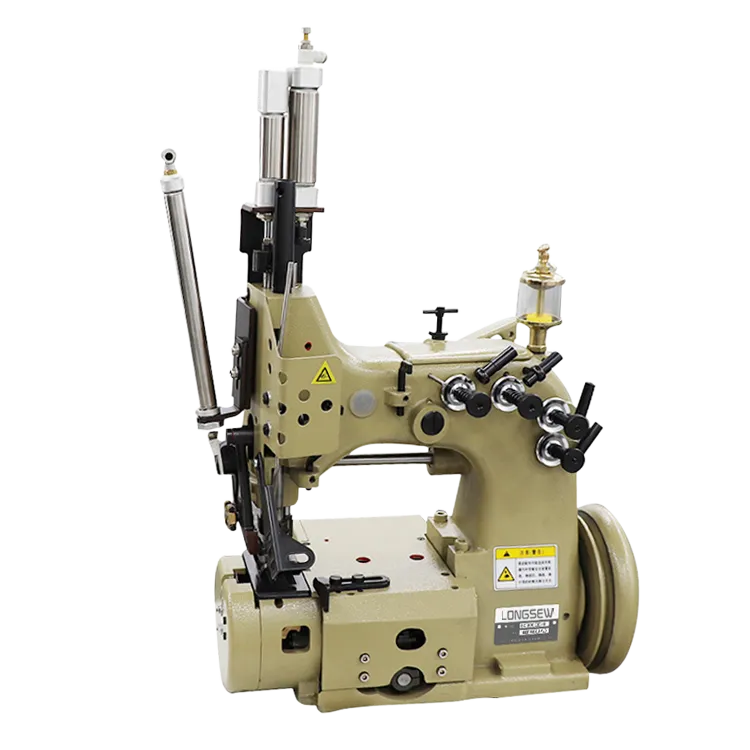

A well-designed woven sack bag sewing machine should possess certain essential characteristics to ensure optimal performance

While there are many benefits to using a hand crank sewing machine, there are some challenges to consider. The learning curve can be steep for those who are accustomed to electric machines that do much of the work automatically. Additionally, sewing large pieces of leather may require physical effort, which can be tiring over extended periods.

The versatility of the modern chain stitch machine is evident in its applications across various sectors. In the garment industry, it is widely used for sewing stretch fabrics and intricate designs, allowing for more intricate patterns without sacrificing quality. Moreover, the machine can be customized with different needle sizes and thread types, further expanding its range of capabilities. This adaptability not only meets the demands of contemporary fashion but also supports innovative design techniques, pushing the boundaries of creative expression in textile production.

Overall, the CB4500 leather sewing machine is a top-of-the-line tool that is perfect for anyone looking to work with leather materials. Its durable construction, advanced features, and range of accessories make it a versatile and reliable choice for professionals and hobbyists alike. With the CB4500 by your side, you can tackle even the most challenging leather projects with confidence and ease.

Tools Required