high quality sewage drainage pump factory

Latest articles

>Slurry Pump

high quality sewage drainage pump factory...

high quality sewage drainage pump factory 【high quality sewage drainage pump factory】

Read MoreSlurry pumps are usually larger than standard pumps, have more horsepower and use stronger bearings and shafts. The most common >type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids pass through a standard centrifugal pump.

high quality sewage drainage pump factory...

high quality sewage drainage pump factory 【high quality sewage drainage pump factory】

Read MoreSlurry pump design

high quality sewage drainage pump factory...

high quality sewage drainage pump factory 【high quality sewage drainage pump factory】

Read MoreSlurry Pump

high quality sewage drainage pump factory...

high quality sewage drainage pump factory 【high quality sewage drainage pump factory】

Read MoreA dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

high quality sewage drainage pump factory...

high quality sewage drainage pump factory 【high quality sewage drainage pump factory】

Read MoreFind the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

high quality sewage drainage pump factory...

high quality sewage drainage pump factory 【high quality sewage drainage pump factory】

Read MoreLifetime use

high quality sewage drainage pump factory...

high quality sewage drainage pump factory 【high quality sewage drainage pump factory】

Read MoreWhat is the optimum seal arrangement for the application?

high quality sewage drainage pump factory...

high quality sewage drainage pump factory 【high quality sewage drainage pump factory】

Read MoreSelecting And Operating A Slurry Pump

high quality sewage drainage pump factory...

high quality sewage drainage pump factory 【high quality sewage drainage pump factory】

Read MoreThe winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

high quality sewage drainage pump factory...

high quality sewage drainage pump factory 【high quality sewage drainage pump factory】

Read More

Popular articles

- Slurry Pump

- What is the best seal arrangement for the application?

- Slurry Pump

- With the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

- Caution: A common mistake is to over-pressurise the box and damage the expensive mechanical seal.

- testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

Latest articles

-

Vertical Slurry Pump

-

Hydrostatic head - i.e. the height to which the slurry must be lifted in the piping system.

-

1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

-

How to choose a slurry pump?

-

To find out more about Aier slurry Pumps, please >contact us.

-

Choosing the right pump for your slurry is critical to getting the most out of it. Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear caused by abrasive slurries. Compared to low-viscosity liquid pumps, target=_blank title=Slurry Pump>slurry pumps are typically larger and often require more horsepower to operate because they are less efficient. Bearings and shafts must also be more robust and durable.

Links

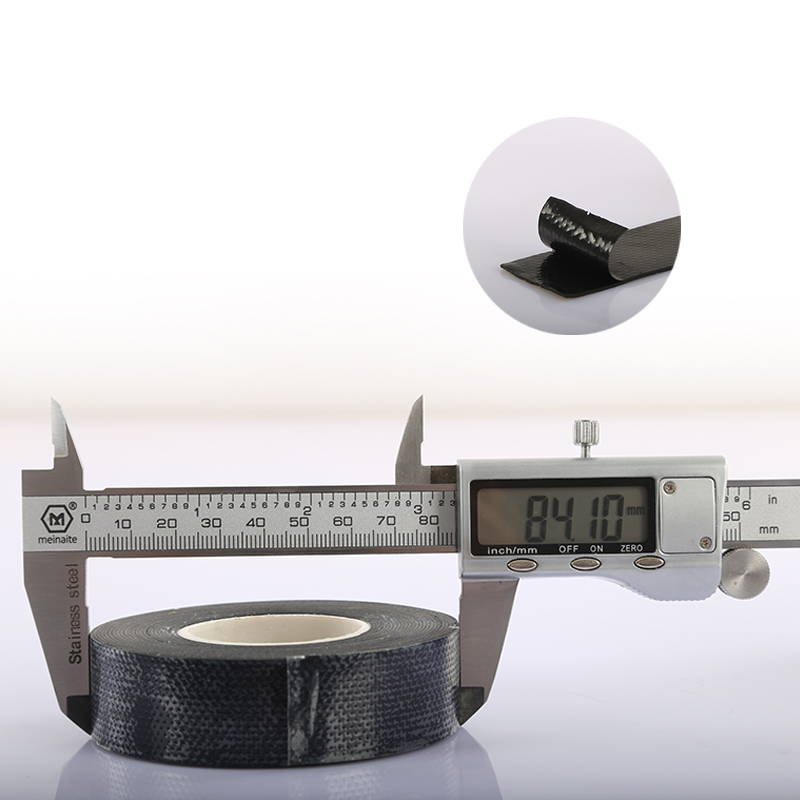

(1) The thermal stability is 180 ℃. At this temperature, the product can be used safely for more than 10 years, saving many after-sales troubles;

Conclusion

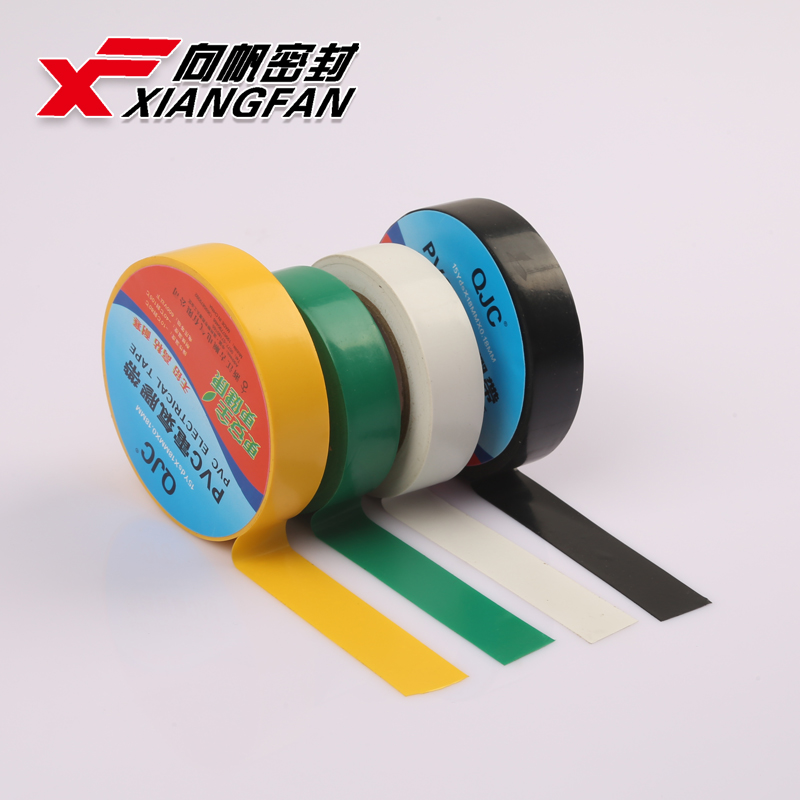

It is also known as insulating tape or insulation tape. Electrical tape is made from a variety of materials, including vinyl, rubber, cloth, and paper.

Market Trends and Availability

yellow warehouse floor tape. Unlike paint, which can be messy and time-consuming to apply, tape can be easily installed and removed as needed. This makes it a flexible option for businesses that may need to modify their floor markings frequently.

The Importance of Fireproof Gasket Tape in Safety and Efficiency

self amalgamating electrical tape. It can withstand temperatures ranging from -65°F to 220°F, making it ideal for use in harsh environments. Its waterproof properties also make it a great choice for outdoor electrical repairs, as it can protect against rain and other weather conditions.

self amalgamating electrical tape. It can withstand temperatures ranging from -65°F to 220°F, making it ideal for use in harsh environments. Its waterproof properties also make it a great choice for outdoor electrical repairs, as it can protect against rain and other weather conditions.Polyethylene film tape (63535) is a 7-mil thick tape coated on one side with a synthetic rubber adhesive. This particular tape is UV-resistant and can form a water-tight seal, making it a good tape for outdoor use. It is designed to be able to mask windows and doors in stucco fabrication and other construction applications. This tape is available in white or red. Available widths range from 2 inches (48 millimeters) to 44 inches (1,118 millimeters).

The well pumps that provide water to private well systems are another area in which you’ll frequently find control boxes. Typically, these designs are relatively simple—but, like all control boxes, they serve a critically important purpose.

3M also makes an electrical tape made of silicone rubber for applications where Class “H” (180°C/356°F) temperatures are encountered i.e., silicone rubber cables.

According to Steve Anderson, a National Joint Apprenticeship and Training Committee (NJATC) director, the NJATC believes strongly in the importance of splice and termination taping skills for electricians and linemen. “Taping is the first thing covered in our cable splice training course, and we spend a lot of time in this area,” Anderson says.

In general, though, most types of electrical tape will start to show signs of degradation at around 70°C.

fire seal tape. It can be applied around electrical outlets, piping, and HVAC ducts to prevent the spread of fire through these vulnerable areas. It can also be used to seal gaps around doors and windows, helping to create a barrier against fire and smoke intrusion.

fire seal tape. It can be applied around electrical outlets, piping, and HVAC ducts to prevent the spread of fire through these vulnerable areas. It can also be used to seal gaps around doors and windows, helping to create a barrier against fire and smoke intrusion. It offers a cost-effective solution that can last for considerable periods under harsh conditions such as extreme cold or heat from the engine bay It offers a cost-effective solution that can last for considerable periods under harsh conditions such as extreme cold or heat from the engine bay

It offers a cost-effective solution that can last for considerable periods under harsh conditions such as extreme cold or heat from the engine bay It offers a cost-effective solution that can last for considerable periods under harsh conditions such as extreme cold or heat from the engine bay pvc black tape.

pvc black tape. 50mm insulation tape. This color-coding system aids in identification, organization, and adherence to safety protocols, making it easier for electricians and technicians to work efficiently.

50mm insulation tape. This color-coding system aids in identification, organization, and adherence to safety protocols, making it easier for electricians and technicians to work efficiently.Electrical tapes are versatile, suited to a multitude of tasks, and when installed properly provide a long-term, effective insulation. According to Anderson, both the NJATC headquarters and local training efforts are strongly supported by industry suppliers, which provide sample products and assist with course development and hands-on instruction. In addition, manufacturers of electrical-grade tapes are generally willing to provide technical support and instruction on proper taping techniques.