high quality slurry pump casing suppliers

Latest articles

Selecting the right pump for slurries is critical to get the most bang for your buck. Basic pump components, such as the impeller size and design, material of construction, and discharge configurations must be considered to ensure the pump will hold up against the wear caused by an abrasive slurry. Slurry pumps are generally larger in size when compared to low-viscosity liquid pumps and usually require more horsepower to operate because they're less efficient. Bearings and shafts must be more rugged and rigid as well.

high quality slurry pump casing suppliers...

high quality slurry pump casing suppliers 【high quality slurry pump casing suppliers】

Read More>Slurry Pump

high quality slurry pump casing suppliers...

high quality slurry pump casing suppliers 【high quality slurry pump casing suppliers】

Read MoreSlurry pump seals

high quality slurry pump casing suppliers...

high quality slurry pump casing suppliers 【high quality slurry pump casing suppliers】

Read MorePositive displacement slurry pumps with limited capacity to deliver high head are used to pump slurry through pipes with very high solids concentrations.

high quality slurry pump casing suppliers...

high quality slurry pump casing suppliers 【high quality slurry pump casing suppliers】

Read MoreThe rule of thumb for setting the water pressure is the same when using the pack box, whether flushing. Mud pump shut-off pressure plus 10% or plus 20 psi, whichever is greater. However, the flow rate is set differently.

high quality slurry pump casing suppliers...

high quality slurry pump casing suppliers 【high quality slurry pump casing suppliers】

Read MoreIf centrifugal, are the impellers of the right design and material?

high quality slurry pump casing suppliers...

high quality slurry pump casing suppliers 【high quality slurry pump casing suppliers】

Read MoreChoosing the right , slurry pump, for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the , slurry pump supplier, will share them with you.+

high quality slurry pump casing suppliers...

high quality slurry pump casing suppliers 【high quality slurry pump casing suppliers】

Read MoreThe FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

high quality slurry pump casing suppliers...

high quality slurry pump casing suppliers 【high quality slurry pump casing suppliers】

Read MoreTypes of slurry pumps

high quality slurry pump casing suppliers...

high quality slurry pump casing suppliers 【high quality slurry pump casing suppliers】

Read MoreBetter safety

high quality slurry pump casing suppliers...

high quality slurry pump casing suppliers 【high quality slurry pump casing suppliers】

Read More

Popular articles

- Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel, Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

- If you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

- Definition of dredge and slurry pumps

- As a pump supplier, Aier is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc. If you want to get more information about >best slurry pump wholesale, welcome to >contact us today or request a quote.

- of a thick consistency, and.

- Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel, Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

Latest articles

-

Damage to slurry pumps can range from burst seals to bearings and component housings wearing out where they join, to impellers corroding due to cavitation or severe wear and so on. However, there are solutions to these problems.

-

Damage to slurry pumps can range from burst seals to bearings and component housings wearing out where they join, to impellers corroding due to cavitation or severe wear and so on. However, there are solutions to these problems.

-

If a centrifugal pump, is the design and material used to construct the impeller suitable for pumping slurries?

-

Fewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - usually 2-5 vanes.

-

A slurry pump is a mechanical device used for the pressure-driven transfer of a fluid mixture (aka slurry). The fluid mixture consists largely of water as a liquid and solids as minerals, sand, gravel, human excrement, drilling mud or mostly crushed material.

-

Selecting And Operating A Slurry Pump

Links

- Enhanced malleability

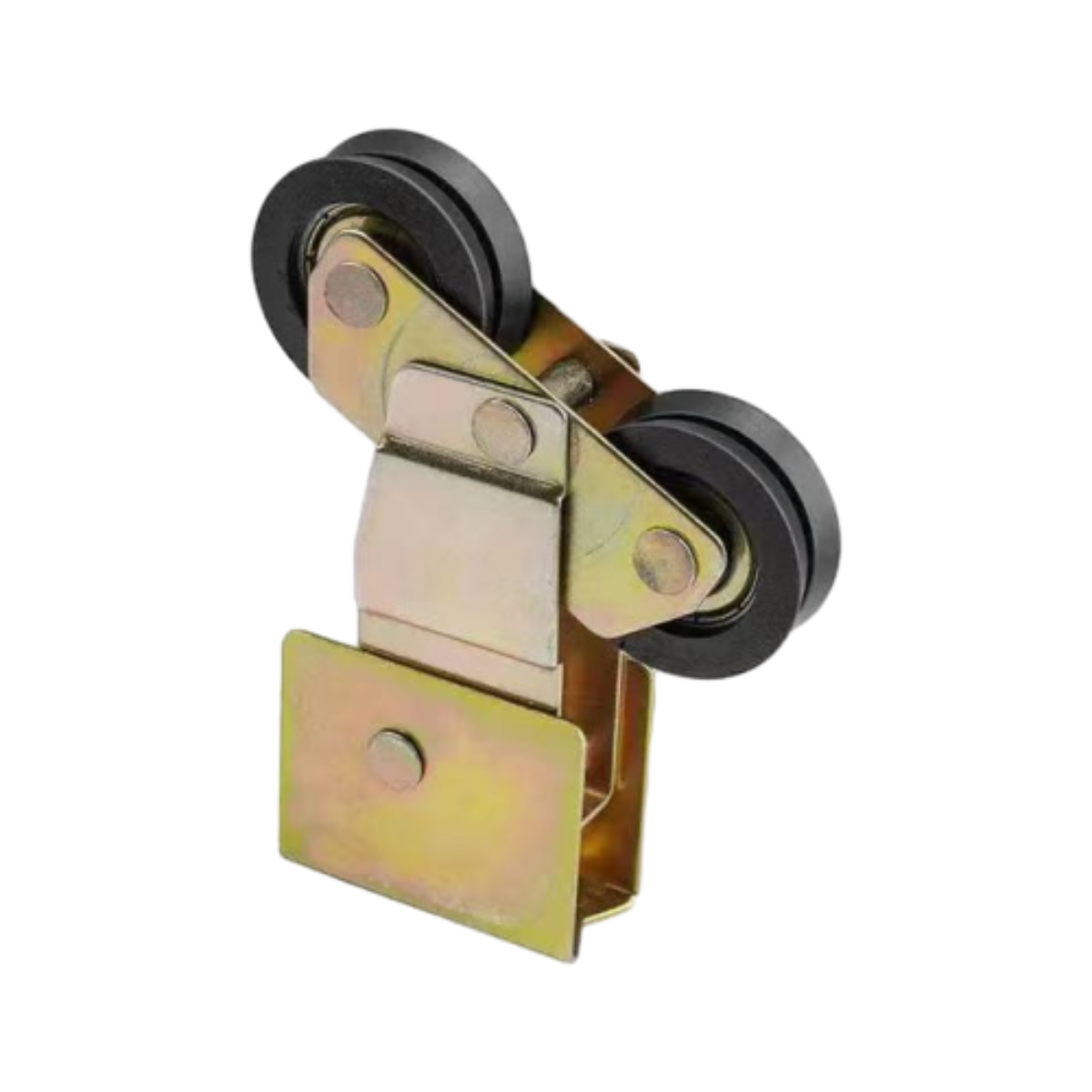

- One of the key benefits of using sliding cabinet rollers is their versatility. They can be installed in a variety of settings, including kitchens, bathrooms, offices, and garages. Whether you need to organize your pantry, create additional storage space in your bedroom closet, or keep your tools and equipment easily accessible in your workshop, sliding cabinet rollers are an ideal solution.

However, these efforts serve to preserve not just the material but also the artistry and history it represents. Over time, the character it acquires transforms your property into something akin to a local treasure.

- Ask questions to salespeople and manufactures to confirm the material type. If given the opportunity, your sales representative will happily show you the differences between the two types and specify the one being quoted.

- Moreover, a professional service guarantees safety and longevity. Incorrectly installed rollers can lead to further damage or accidents. Professionals ensure the job is done right the first time, minimizing the risk of future issues. They also offer warranties on their work, providing peace of mind for homeowners.

Additionally, cast iron fence panels are easy to install. With the proper tools and know-how, homeowners can easily set up their panels without the need for professional installation. This makes cast iron fence panels a cost-effective choice for those looking to add a touch of elegance and security to their property without breaking the bank.

Excellent for welded parts and assemblies

Custom manufacturing

Repurposing Within the Home or Garden

Wrought iron fence ornaments are more than just decorative elements; they are timeless pieces that add character and elegance to any property. With their rich history, durability, and aesthetic versatility, these ornaments can elevate the allure of traditional and modern homes alike. By incorporating wrought iron into your fencing or landscaping, you not only enhance the visual appeal but also invest in a piece of art that will last for generations. Whether you're drawn to intricate designs or minimalist styles, there’s a wrought iron ornament to suit every taste, ensuring your fence is a true reflection of your unique personality.

It is quite popular and can be used with self-tapping screws or merely threaded to take a machine screw.

How Do You Manufacture Aluminum Profiles For Windows and Doors?

In a nutshell, the main difference between these two types of surface finish is the oxide layer. Anodized finish has a layer of oxide, whereas mill finish does not have the oxide layer.

Specification Of Aluminum Profiles For Window and Door System

aluminum window channel extrusion. The ability to create customized profiles enables the realization of unique architectural visions, where windows can seamlessly integrate with the overall design scheme. This flexibility allows for the creation of visually stunning buildings that push the boundaries of traditional architecture.

aluminum window channel extrusion. The ability to create customized profiles enables the realization of unique architectural visions, where windows can seamlessly integrate with the overall design scheme. This flexibility allows for the creation of visually stunning buildings that push the boundaries of traditional architecture.From vinyl and metal to classic wood and even chain-link, there are so many different fencing styles to choose from these days. On top of that, each style comes with its own advantages and disadvantages too.

Decorative wrought iron fence panels are a stylish and elegant way to enhance the look of any property. These ornate panels are not only functional for providing security and privacy, but they also add a touch of sophistication to any outdoor space.

Start by removing the screen door from its frame. This is usually done by lifting it straight up from the track and pulling it away from the opening. Be sure to have someone assist you if the door is heavy or cumbersome.

Custom Fabrications. Ornamental iron (steel) fences are easy to customize. Manufacturers and fence installers can create custom decorative fence solutions on most any budget.

Some of the commonly used ways include the following;

Begin by removing the screen door from its frame. This is usually done by lifting the door slightly and sliding out the bottom retention clips or unscrewing them if they're fixed. If your door has a handle, remove any screws holding it in place as well. Be cautious not to damage the door or surrounding frame during this process.

Architectural Masterpieces

okrasná liatina