china mining slurry pump suppliers

Latest articles

600WN to 1000WN dredge pumps are of double casings, single stage cantilevered centrifugal pumps. These pumps are equipped with frame and lubrication is force thin oil. The design of double casing the pump working till the volute liner almost worn down and guarantee no leakage when volute liner is worn down.

china mining slurry pump suppliers...

china mining slurry pump suppliers 【china mining slurry pump suppliers】

Read MoreSlurry Pump

china mining slurry pump suppliers...

china mining slurry pump suppliers 【china mining slurry pump suppliers】

Read MoreHow does a dredge pump work?

china mining slurry pump suppliers...

china mining slurry pump suppliers 【china mining slurry pump suppliers】

Read More- Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

china mining slurry pump suppliers...

china mining slurry pump suppliers 【china mining slurry pump suppliers】

Read MoreCapacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel, Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

china mining slurry pump suppliers...

china mining slurry pump suppliers 【china mining slurry pump suppliers】

Read More- Hydraulic efficiency is as important as the material, as efficiency is related to wear. The swept-back design of the impeller blades minimises the separation of solids from the carrying fluid, resulting in a more uniform flow. This results in a slower wear rate.

china mining slurry pump suppliers...

china mining slurry pump suppliers 【china mining slurry pump suppliers】

Read More600WN to 1000WN dredge pumps are of double casings, single stage cantilevered centrifugal pumps. These pumps are equipped with frame and lubrication is force thin oil. The design of double casing the pump working till the volute liner almost worn down and guarantee no leakage when volute liner is worn down.

china mining slurry pump suppliers...

china mining slurry pump suppliers 【china mining slurry pump suppliers】

Read MoreThe dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

china mining slurry pump suppliers...

china mining slurry pump suppliers 【china mining slurry pump suppliers】

Read MoreThe construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

china mining slurry pump suppliers...

china mining slurry pump suppliers 【china mining slurry pump suppliers】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

china mining slurry pump suppliers...

china mining slurry pump suppliers 【china mining slurry pump suppliers】

Read More

Popular articles

- Under ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

- Slurry pump design

- - Easy installation - Submersible pumps are relatively easy to install since the motor and worm gear are a single unit.

- Consideration should be given to installing mixers on guide rods in the catch basin/tank to keep solids in suspension and avoid settling in the catch basin/tank. When investing in a slurry pump, you want to pump slurry that includes solids, not just dirty water. Therefore, it is important to make sure that the pump is doing this; by using an agitator, the pump is fed with solids and pumping the slurry.

- Carbon transfer

- Typical Applications of slurry pump

Latest articles

-

Choosing the Right Pump for Flue Gas Desulphurisation

-

The impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

-

- Keeping clean catch basins clean from solids

-

All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

-

Are the pump discharge components suitable for the slurry being pumped?

-

One of the most frequently asked questions from our team of pump experts is: How do I pump slurry? With this in mind, our team of experts have provided a useful guide to pumping slurry.

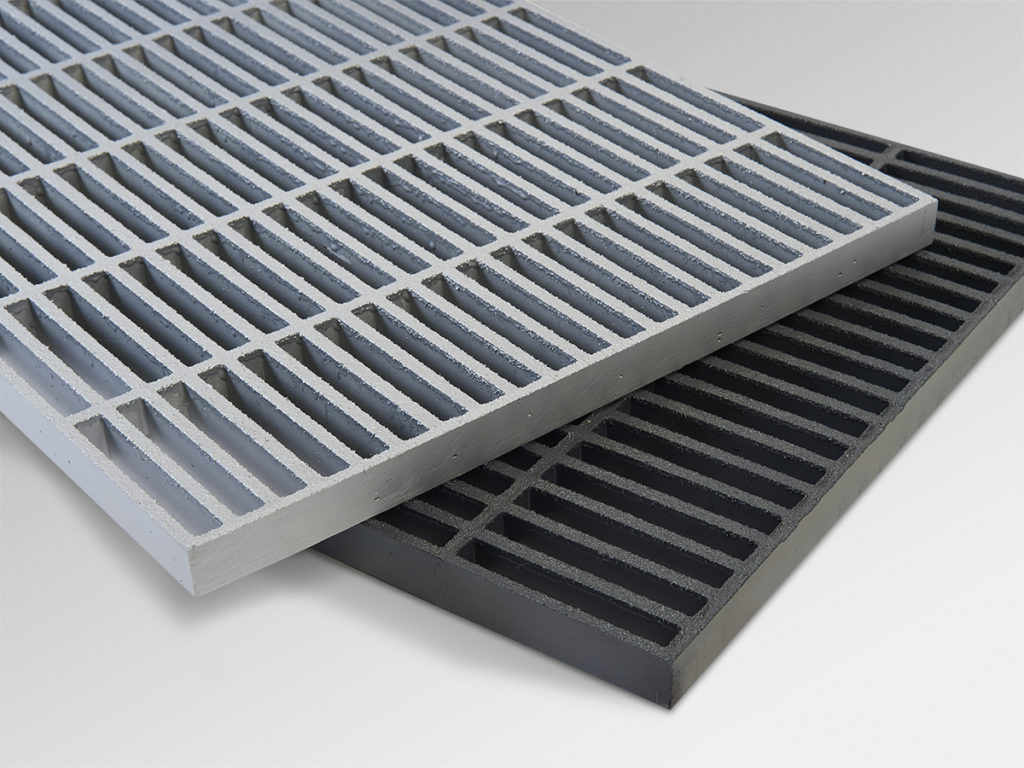

Heavy Duty Fiberglass Grating:

In Packaged Metering Manholes, when used with our molded diamond plate surface, recessed grating creates a safe, stable working environment for the operator to work from.

The selection of the resin option also depends upon the purpose of use. For the general purposes Orthophthalic Polyester is more suitable. Some other resin options are Vinyl Ester, Isophthalic Polyester (or ISO), Fire Retardant and USDA certified. All resin options are UV Resistant and are designed for different purposes and conditions.

Available in various colors and styles, such as green, yellow, grey, orange and various other custom colors, fiberglass grating is more appealing in look as well. To ensure the longevity of the product, color is permanently added to the resin formula. The color and style of the grating are decided, while keeping the safety hazards in account. Some of the most prominent industries that use fiberglass gratings are waste water treatment plants, food processing plants, aquariums, power plants, chemical plants, lift stations, plating shops and also plants with canning and beverage facilities.