china rubber impeller of slurry pump

Latest articles

- transport solids hydraulically

china rubber impeller of slurry pump...

china rubber impeller of slurry pump 【china rubber impeller of slurry pump】

Read More- By increasing the size of the worm housing, the speed at which the media moves is reduced. This lower velocity translates into lower wear.

china rubber impeller of slurry pump...

china rubber impeller of slurry pump 【china rubber impeller of slurry pump】

Read MorePumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.

china rubber impeller of slurry pump...

china rubber impeller of slurry pump 【china rubber impeller of slurry pump】

Read MoreSlurry pump considerations

china rubber impeller of slurry pump...

china rubber impeller of slurry pump 【china rubber impeller of slurry pump】

Read MoreLonger maintenance intervals

china rubber impeller of slurry pump...

china rubber impeller of slurry pump 【china rubber impeller of slurry pump】

Read More>Dredge Pump

china rubber impeller of slurry pump...

china rubber impeller of slurry pump 【china rubber impeller of slurry pump】

Read MoreA dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

china rubber impeller of slurry pump...

china rubber impeller of slurry pump 【china rubber impeller of slurry pump】

Read MoreAll products are mainly supplied to environmental protection, wastewater treatment, urban water supply and drainage, mine, metallurgy, coal, petrochemical, building material, thermal power FGD, river dredging, tailing disposal and other fields.

china rubber impeller of slurry pump...

china rubber impeller of slurry pump 【china rubber impeller of slurry pump】

Read MoreIf youve ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. Theres no doubt that the slurry on the pump is hard. But the more you know about whats being pumped, the better your pump selection will be, resulting in longer mean time between failures.xa0Next, the , slurry pump supplier, will share the following content with you.

china rubber impeller of slurry pump...

china rubber impeller of slurry pump 【china rubber impeller of slurry pump】

Read More600WN to 1000WN dredge pumps are of double casings, single stage cantilevered centrifugal pumps. These pumps are equipped with frame and lubrication is force thin oil. The design of double casing the pump working till the volute liner almost worn down and guarantee no leakage when volute liner is worn down.

china rubber impeller of slurry pump...

china rubber impeller of slurry pump 【china rubber impeller of slurry pump】

Read More

Popular articles

- >Slurry pumps are typically larger than standard pumps, with more horsepower and stronger bearings and shafts. The most common type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids move through a standard centrifugal pump.

- To reduce wear, reduce the pump discharge pressure to the lowest possible point.

- Working principle

- Horizontal pumps are the most commonly used type of slurry pump and therefore have the advantage of being easy to install or maintain, a wide range of flow parameters to choose from and a wide range of design materials to choose from. One of the advantages of vertical pumps, however, is the relatively small amount of floor space required for installation.

- Packing the box seal

- Slurry Pump

Latest articles

-

When slurry pump working, which is the motor drives the impeller rotation. That is the impeller on the slurry work which increases the kinetic energy of the slurry. At the same time, the slurry flows to the edge of the impeller due to inertia and is discharged from the discharge pipe at a high speed.

-

Vertical Slurry Pumps Pump Sewage More Efficiently

-

Another way of classifying the type of slurry pump installation is dry installation or wet installation. Dry installation pumps have the hydraulic end and drive located outside the liquid, whereas wet installation pumps (such as submersible pumps) operate within a catch basin or slurry. Submersible pumps do not require much support structure and therefore do not take up much space. Depending on the type of operation and installation required, the preferred method of pump installation is determined.

-

Selecting And Operating A Slurry Pump

-

Advantages of rubber

-

Choosing the right target=_blank title=Slurry Pump>slurry pump for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share them with you.

Links

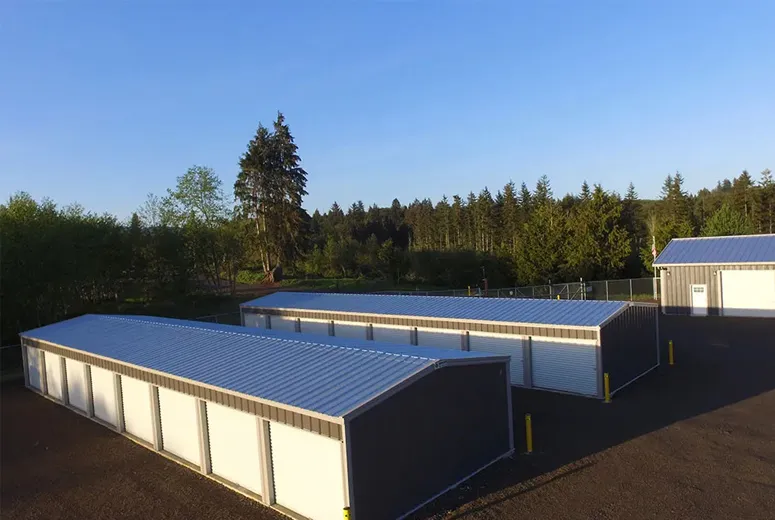

Versatile Design Options

In the design stage, we will need you to provide the parameters like rainfall, wind load, snow load, seismic grade, loading capcity of deck floor etc. At the same time, we design and build material strength, material thickness, and cross-sectional characteristics of metal warehouses that also meet international standards.

Versatility in Design

The Advantages of Metal Garage Delivered and Installed

Variety of Options

Optimal Use of Space

Conclusion

Innovation and Technology Integration

For example, many metal barn manufacturers provide options for adding lean-tos for additional storage or sheltered areas for livestock

. These extensions can be tailored to fit the existing landscape and contribute to the overall efficiency of the farm. Moreover, the versatility of metal barns allows for future expansions, accommodating growing operations without the need for complete overhauls.metal barn manufacturers

In conclusion, building workshops are invaluable spaces that transcend mere construction. They provide an avenue for skill development, creativity, collaboration, and sustainability, all while fostering connections within communities. As individuals engage in building and crafting, they not only create tangible products but also build confidence, interpersonal relationships, and a deeper appreciation for the art of making. Whether one is a novice or an experienced artisan, the journey through a building workshop can be transformative, leaving lasting impacts that extend well beyond the workshop environment. In a world increasingly driven by technology, these workshops serve as a reminder of the beauty and significance of tangible skills and creativity.

Steel-Integrated Renewable Energy Systems: Design steel buildings that seamlessly incorporate wind turbines, solar panels, and other renewable energy technologies into the structure itself.

3. Durability and Longevity Constructed with treated wood and metal roofing, pole barn loafing sheds are designed to withstand various weather conditions, from heavy rain to intense sunlight. Properly maintained, these structures can last decades, providing long-term shelter for livestock.

In the realm of modern agriculture, efficiency and innovation are key to thriving in an increasingly competitive market. Large agricultural sheds have emerged as vital structures that play a significant role in enhancing farming operations. These expansive buildings provide farmers with the necessary space and versatility to manage their resources effectively, ultimately contributing to higher productivity and sustainable practices.

The Versatility and Benefits of a 6x10 Metal Shed

Protection from Environmental Elements

Understanding Agricultural Sheds Functions and Importance

As agriculture continues to evolve, farmers are increasingly seeking durable, cost-effective, and versatile solutions to their building needs. One of the most innovative and practical advancements in this area is the use of metal buildings on farms. Farm metal buildings have gained popularity due to their numerous advantages, which cater to a wide range of agricultural activities, from livestock housing to equipment storage and even processing facilities.

In conclusion, custom steel barns offer a multitude of benefits that make them an attractive option for various applications. Their durability, customization options, and versatility make them suitable for both agricultural needs and diverse recreational or business purposes. Furthermore, the speed of construction and environmentally-friendly nature of steel add to their appeal. Whether you’re a farmer looking for efficient storage solutions or a homeowner seeking an engaging space, a custom steel barn may be the perfect fit for your needs. Embrace the future of construction and explore the possibilities that a custom steel barn can bring to your property.

When it comes to shed designs, the focus often lies on functionality and practicality. However, the aesthetic appeal of a shed can be dramatically enhanced by simple modifications, one of which is the addition of window frames. Shed window frames not only serve a crucial structural purpose but also elevate the overall look of the outdoor structure, making it more inviting and visually pleasing.

One of the primary benefits of a metal shed is its durability. Made from high-quality galvanized steel or aluminum, these sheds are resistant to warping, cracking, and rotting—common issues faced by wooden sheds. Additionally, metal sheds can withstand extreme weather conditions, ensuring that your stored items remain safe and sound throughout the seasons. Unlike wooden structures that may require regular upkeep and maintenance, a 12x10 metal shed can serve you well for years with minimal care.

Aesthetic Appeal

In today's fast-paced world, efficient logistics and supply chain management are paramount for businesses aiming to thrive in the global market. One of the critical components of effective logistics is the design and construction of warehouses. Warehouse buildings serve not only as storage facilities but also as strategic hubs that facilitate the smooth flow of goods from manufacturers to consumers.

Modular Workshop Buildings A Flexible Solution for Modern Industries

Constructed using a method known as post-frame building, grey and white pole barns are designed for longevity. The post-frame technique involves setting large wooden posts into the ground and then attaching walls and roofs, creating a sturdy and resilient structure. This method allows for increased insulation and energy efficiency, which is a significant advantage for homeowners looking to reduce their utility bills.

Sustainability and Cost-Effectiveness

Understanding the technical aspects of steel fabrication and erection processes is equally significant. Estimators should be well-versed in different steel types, grades, and standard practices within the industry. Knowledge of relevant codes and regulations is also vital, helping to ensure compliance and mitigate potential issues that could arise during construction.

steel buildings and structures estimator

Sustainability is increasingly important in our modern society, and steel barns and garages can play an essential role in this regard. Steel is one of the most recycled materials on the planet, with a significant percentage of new steel being made from recycled sources. By choosing steel for construction, owners are contributing to a reduction in waste and promoting a more sustainable future. Additionally, many manufacturers now offer environmentally friendly options, such as energy-efficient insulation and roofing materials that further reduce the carbon footprint of these buildings.

1. Speed of Construction One of the most significant advantages of prefabricated steel structures is the speed of assembly. With major components prefabricated, the on-site construction time is significantly reduced. While traditional projects can take months or even years to complete, a prefabricated steel structure can be erected in a matter of weeks. This swift timeline is particularly advantageous for businesses and organizations seeking to minimize downtime and maximize efficiency.

Exploring the Benefits of Prefab Steel Building Manufacturers

Cost-Effective Living Solutions

Ideal for Various Uses

One of the most significant advantages of modular workshop buildings is their speed of construction. Traditional building methods can take several months, or even years, to complete a project. In contrast, modular buildings can be assembled in a fraction of the time—often within weeks. This rapid construction process can significantly reduce downtime for businesses, allowing them to start operations sooner and enhancing overall productivity.

In the world of construction and design, metal car garage buildings have carved a significant niche

. Increasingly favored by homeowners, businesses, and automotive enthusiasts alike, these structures offer a combination of durability, functionality, and aesthetic appeal that traditional wooden garages often cannot match.Another benefit that steel has over wood is that steel is not affected by rot, mold or mildew. There’s no need to call out a pest control person every year to spray for them – termites find steel unappetizing.

In recent years, the construction industry has witnessed a significant shift towards metal structures, largely driven by the growing demand for durability, energy efficiency, and cost-effectiveness. As a result, metal building suppliers have emerged as key players in providing innovative solutions that meet these demands. This article explores the benefits of metal buildings, the role of suppliers, and the future of this industry.

Flat pack metal sheds are designed for convenience and accessibility. Delivered in flat boxes, these sheds can be easily transported and maneuvered to your desired location. Unlike traditional wooden sheds, which can be cumbersome and heavy, flat pack options eliminate the heavy lifting often associated with outdoor installations. With just a few tools – and often just a couple of hours – you can have a secure storage space right in your backyard.

Advantages and disadvantages of steel for warehouse construction

2. Quick Construction Pole barn loafing sheds are relatively simple to construct. The pole barn design allows for faster assembly, allowing farmers to have a shelter ready in a short time. This rapid construction is especially important during adverse weather conditions or when new livestock arrives.

pole barn loafing shed

Additionally, companies are increasingly adopting practices like recycling, waste reduction, and sustainable sourcing in their warehouse operations. Not only does this contribute positively to the environment, but it also enhances a company's brand image and meets the changing expectations of consumers.

The advancement of technology has led to innovative design solutions within the realm of farm buildings. Manufacturers are increasingly incorporating smart technologies into their structures. For example, climate control systems can automatically adjust to environmental conditions, ensuring that crops or livestock remain in ideal settings regardless of external weather changes.

farm building manufacturers

Strength and Durability

4. Install the New Frame Position the new frame and secure it with screws. Ensure it is level and plumb. Use shims as necessary to fill any gaps.

3. Location The geographic location of the construction site plays a crucial role in pricing. Transportation costs for the prefabricated components can rise significantly for remote areas, and local regulations might require additional permits or inspections.

Eco-Friendly Options