high quality single stage vertical slurry pump suppliers

Latest articles

If a centrifugal pump, is the design and material used to construct the impeller suitable for pumping slurries?

high quality single stage vertical slurry pump suppliers...

high quality single stage vertical slurry pump suppliers 【high quality single stage vertical slurry pump suppliers】

Read MorePumping slurry can cause excessive wear and tear on the pump and its components as the mud can clog the suction and discharge lines.

high quality single stage vertical slurry pump suppliers...

high quality single stage vertical slurry pump suppliers 【high quality single stage vertical slurry pump suppliers】

Read MoreThe Mud pumps need to be equipped with auxiliary equipment, but slurry pumps not. They often need to use with high-pressure water pump when mud pump working. The high-pressure pump sent the water that larger than the mud pump pressure to the leakproof packing. Then protect the packing. Otherwise, it is easy to make the seal part wear. But the wear-resistant slurry pumps can complete the transportation work independently, which not need to equip other auxiliary equipment.

high quality single stage vertical slurry pump suppliers...

high quality single stage vertical slurry pump suppliers 【high quality single stage vertical slurry pump suppliers】

Read MoreSome models can generate discharge pressures up to 260 ft. (80 m).

high quality single stage vertical slurry pump suppliers...

high quality single stage vertical slurry pump suppliers 【high quality single stage vertical slurry pump suppliers】

Read MoreThe construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

high quality single stage vertical slurry pump suppliers...

high quality single stage vertical slurry pump suppliers 【high quality single stage vertical slurry pump suppliers】

Read More3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

high quality single stage vertical slurry pump suppliers...

high quality single stage vertical slurry pump suppliers 【high quality single stage vertical slurry pump suppliers】

Read MoreIt is important that the pump you choose has components that will not wear out from abrasive slurries.

high quality single stage vertical slurry pump suppliers...

high quality single stage vertical slurry pump suppliers 【high quality single stage vertical slurry pump suppliers】

Read MoreOn the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

high quality single stage vertical slurry pump suppliers...

high quality single stage vertical slurry pump suppliers 【high quality single stage vertical slurry pump suppliers】

Read MoreWhat style of pump is suitable?

high quality single stage vertical slurry pump suppliers...

high quality single stage vertical slurry pump suppliers 【high quality single stage vertical slurry pump suppliers】

Read MoreOne of the most frequently asked questions from our team of pump experts is: How do I pump slurry?xa0With this in mind, our team of experts have provided a useful guide to pumping slurry.

high quality single stage vertical slurry pump suppliers...

high quality single stage vertical slurry pump suppliers 【high quality single stage vertical slurry pump suppliers】

Read More

Popular articles

- The Company Adopts Advanced Computer Aided Engineering Software

- Rubber is lighter and softer than other wear lining materials. This aids installation because it is easier to lift and install quickly and efficiently. Positive results for the health and safety of workers in the field.

- To reduce wear, reduce the pump discharge pressure to the lowest possible point.

- Choosing The Right Slurry Pump For Your Application

- A >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

- The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

Latest articles

-

- Hydraulic efficiency is as important as the material, as efficiency is related to wear. The swept-back design of the impeller blades minimises the separation of solids from the carrying fluid, resulting in a more uniform flow. This results in a slower wear rate.

-

WZ series slurry pumps are developed on the wide adaption of both home and abroad advance technology and many years of slurry pump design and field operation experiences.

-

Especially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

-

Examples of these dubious enhancements to impeller adjustment abound in the industry. One of these is the adjustable wear ring or suction liner to maintain the recommended clearance between the impeller front shroud and the throat bushing face. Almost all >slurry pumps, including AIER® slurry pumps, have features to ensure that this equipment specification can be maintained over time.

-

Some models can generate discharge pressures up to 260 ft. (80 m).

-

Find the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

Links

Not merely the component for joining panels together, metal fence posts are also the primary anchors for any installation. By acting as a fence’s “feet,” posts provide stability and security necessary to keep the panels firmly in place. Their height can vary to accommodate whichever panel height you’ve chosen. Matching the post to the panel is essential. These components rely on 2″ square tubing and are visually distinct from the panels. To anchor iron safety fence panels to their corresponding posts, special hardware called a “sleeve,” or a “bracket” attaches the top and bottom rails to the post. Then they’re permanently attached using either screws or a weld.

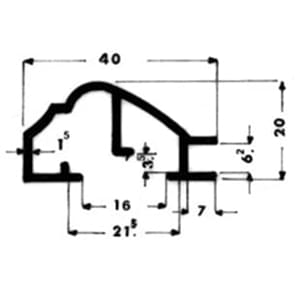

Essentially, aluminum profiles with relatively thick materials tend to be costlier than vice versa.

Elegant Embellishments: Cast Iron Panels

small metal box with latch. Its sturdy latch provides security, ensuring that its contents remain safe and protected. Perhaps you use it to store your most precious belongings, knowing that they are always close at hand and secure from prying eyes.

The production of aluminum fences is scalable to huge numbers. An aluminum fence is typically made using a manufacturing process known as extrusion. This procedure entails nothing more than moving blocks of aluminum through a dying system.

If you’ve determined that the rollers need to be replaced, locate the screws that hold them in place. Use the appropriate screwdriver to remove these screws and take out the damaged rollers. Insert the new rollers in the same position, securing them with screws. Ensure they are appropriately aligned and able to move freely without obstruction.

If you email the company, how quickly do they get back to you? Same goes with a phone call. If you emailed or called and have not heard anything back the same or next day when they are trying to earn your business, how receptive do you think they will be after they have your money? A place where you can get a direct extension and name is going to be much more helpful and receptive than a place with a generic email and no direct people to work with.

Therefore, purchasing more aluminum profiles for windows and doors is seemingly more cost-effective and vice versa.

Aluminum ornamental iron fencing is becoming the most popular type of fencing especially for residential fencing. Cost is definitely the driving force because aluminum fencing can be manufactured in large quantities at a faster production rate and at a lower cost of production. Aluminum fencing is produced through an extrusion process that basically pushes aluminum blocks of materials through a die system that adheres to the contour of that particular die. Once the piece is formed, the components of the different style of ornamental fencing goes through several steps of priming and powder coating, boxed and ready for shipment from the manufactures to different distributors located throughout the U.S.

With a designated storage place, like a metal security box, you can ensure your keys are always in a known location, reducing the chances of misplacement With a designated storage place, like a metal security box, you can ensure your keys are always in a known location, reducing the chances of misplacement

With a designated storage place, like a metal security box, you can ensure your keys are always in a known location, reducing the chances of misplacement With a designated storage place, like a metal security box, you can ensure your keys are always in a known location, reducing the chances of misplacement metal security box for car keys.

metal security box for car keys.