centrifugal slurry pump spares factory

Latest articles

With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

centrifugal slurry pump spares factory...

centrifugal slurry pump spares factory 【centrifugal slurry pump spares factory】

Read MoreSubmersible slurry pump pumps offer many advantages over dry and semi-dry (cantilever) mounted pumps.

centrifugal slurry pump spares factory...

centrifugal slurry pump spares factory 【centrifugal slurry pump spares factory】

Read MoreThe construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

centrifugal slurry pump spares factory...

centrifugal slurry pump spares factory 【centrifugal slurry pump spares factory】

Read MoreThe first major requirement for >slurry pumps is to provide adequate service life. The erosive and corrosive effects of slurries, such as the impact of high velocity flow of liquid/solid mixtures, can be really challenging. In many applications, some of the solids in the mixture are larger than the particles normally specified; therefore, the pump should be able to pass through them without causing any damage or operational problems.

centrifugal slurry pump spares factory...

centrifugal slurry pump spares factory 【centrifugal slurry pump spares factory】

Read MoreLow slurry flow rates

centrifugal slurry pump spares factory...

centrifugal slurry pump spares factory 【centrifugal slurry pump spares factory】

Read MoreHorizontal centrifugal pumps are commonly used for slurry service, but vertical and other types of pumps are better suited to certain specific applications. Centrifugal pumps for handling slurries have features tailored to specific services that reflect the corrosive or abrasive nature of the slurry and the concentration of solids. These may include the choice of materials, the use of liners or even different drive sizes.

centrifugal slurry pump spares factory...

centrifugal slurry pump spares factory 【centrifugal slurry pump spares factory】

Read MoreThe type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

centrifugal slurry pump spares factory...

centrifugal slurry pump spares factory 【centrifugal slurry pump spares factory】

Read MoreDesire for higher efficiency than centrifugal pumps

centrifugal slurry pump spares factory...

centrifugal slurry pump spares factory 【centrifugal slurry pump spares factory】

Read MoreThe concentration of solids in the slurry - measured as a percentage of the total volume.

centrifugal slurry pump spares factory...

centrifugal slurry pump spares factory 【centrifugal slurry pump spares factory】

Read MoreSlurry Pump

centrifugal slurry pump spares factory...

centrifugal slurry pump spares factory 【centrifugal slurry pump spares factory】

Read More

Popular articles

- Slurry Pump VS Mud Pump

- Slurry Pump

- Repairable - target=_blank title=Rubber Lined Slurry Pumps>Rubber lined slurry pumps can be repaired by simply replacing the bushing.

- WZ series slurry pumps are developed on the wide adaption of both home and abroad advance technology and many years of slurry pump design and field operation experiences.

- We know that the right rubber and ceramic liners work very well. They also last longer and can withstand more demanding use. They can also be replaced, thereby extending the life of the pump while reducing operating costs. You can also customise your pump with a variety of ceramic parts, including bushings, pump housings, impellers, wet ends and even seals.

- The mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete.

Latest articles

-

Find the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

-

- Low noise level - Operating underwater results in low noise or even silent operation.

-

Dredge Pump

-

- Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

-

Slurry pipe diameter.

-

Horizontal pumps are the most commonly used type of slurry pump and therefore have the advantage of being easy to install or maintain, a wide range of flow parameters to choose from and a wide range of design materials to choose from. One of the advantages of vertical pumps, however, is the relatively small amount of floor space required for installation.

5. Automotive Applications In the automotive industry, red insulation tape is often utilized for wiring repairs or modifications in vehicles. Its ability to withstand heat and moisture makes it suitable for use in engine compartments and other demanding environments.

For more electrical articles, bookmark AC Electric!

Another noteworthy feature is its resistance to extreme temperatures. Self-fusing rubber tape can typically withstand temperatures ranging from -20°C to 150°C (-4°F to 302°F), making it suitable for both high- and low-temperature environments. This attribute makes it especially useful in electrical applications, automotive repairs, and around the home, where temperature fluctuations are common.

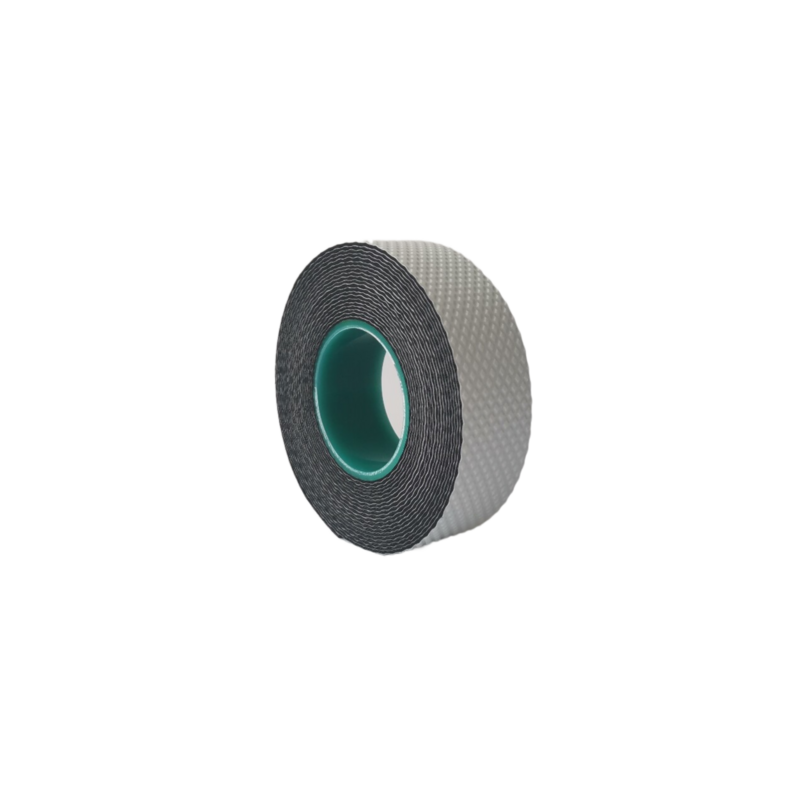

self fusing rubber tape

vulcanizing tape. The tape will adhere to itself and create a tight, secure bond that is resistant to moisture and corrosion.

Plastic wiring loom wraps are generally more rigid and durable, making them ideal for protecting wires in areas where they are likely to be exposed to moisture or physical damage. Fabric wraps, on the other hand, are more flexible and breathable, allowing for better airflow and heat dissipation around the wires.

Despite its many benefits, Flex Tape is not without its limitations. While it can be used to fix a wide range of issues, it is not a permanent solution and may need to be replaced periodically. It is also not recommended for use on flexible materials or surfaces that constantly move or bend, as it may not adhere properly.

J50 High-voltage EPR Rubber Tape

Essential Components and Their Roles

It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments

It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments insulation tape yellow. It can also be easily trimmed to size using scissors or a utility knife, allowing workers to customize the tape to fit their specific needs.

insulation tape yellow. It can also be easily trimmed to size using scissors or a utility knife, allowing workers to customize the tape to fit their specific needs.The Difference Between Silicone Rubber Tape and Rubber Repair Tape

If you’re like most people, you probably have a roll of electrical tape sitting in your toolbox. And while you may use it for a variety of tasks, one question always comes to mind: is electrical tape heat resistant?

Moreover, fire-resistant drywall tape is typically made from materials including fiberglass and special polymers that enhance its performance during a fire. These materials can withstand higher temperatures and resist melting, which contributes to maintaining the integrity of the drywall installation. Builders and contractors are increasingly recognizing that investing in fire-resistant materials, including tape, is not just about compliance with codes but truly about prioritizing the safety of occupants.

fire resistant drywall tape

3M also makes an electrical tape made of silicone rubber for applications where Class “H” (180°C/356°F) temperatures are encountered i.e., silicone rubber cables.

Fire seal tape is widely used in numerous applications throughout the construction process. For instance, it is often applied in fire-rated walls and ceilings to seal penetrations created by electrical, plumbing, and HVAC installations. These penetrations can act as channels for smoke and heat, compromising the fire-resistance of a structure. By using fire seal tape, contractors can effectively minimize these vulnerabilities, thus enhancing the overall safety of the building.

Benefits of Using Control Boxes

5. Sustainability Practices

Here at Swift, we stock a number of different electrical tapes. Some are adhesive, some are not and somewhere in the middle are our self-fusing tapes. These don't stick to surfaces but they do stick to themselves.

PVC (Polyvinyl Chloride) electrical insulation tape is a type of adhesive tape made from durable plastic material that is known for its excellent insulating properties. It is designed to withstand high temperatures and is resistant to moisture, chemicals, and abrasion. The tape typically comes in various colors, although black remains the most popular choice for electrical applications.

Colour: Black