high quality submersible pump factory

Latest articles

As new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumpsxa0help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

high quality submersible pump factory...

high quality submersible pump factory 【high quality submersible pump factory】

Read More- By increasing the size of the worm housing, the speed at which the media moves is reduced. This lower velocity translates into lower wear.

high quality submersible pump factory...

high quality submersible pump factory 【high quality submersible pump factory】

Read MorePumping slurry can cause excessive wear and tear on the pump and its components as the mud can clog the suction and discharge lines.

high quality submersible pump factory...

high quality submersible pump factory 【high quality submersible pump factory】

Read MoreIf the exact in-pump viscosity of the product is unknown, CSI can help

high quality submersible pump factory...

high quality submersible pump factory 【high quality submersible pump factory】

Read MoreAs described below, there are several >types of pumps that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

high quality submersible pump factory...

high quality submersible pump factory 【high quality submersible pump factory】

Read Moresets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

high quality submersible pump factory...

high quality submersible pump factory 【high quality submersible pump factory】

Read MoreA typical pump solution for this application is to install a hard metal >slurry pump to withstand these types of conditions. Hard metal pumps need to be able to withstand the most severe abrasive slurry service and they also need to be designed to be extremely easy to maintain and safe.

high quality submersible pump factory...

high quality submersible pump factory 【high quality submersible pump factory】

Read MoreA >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

high quality submersible pump factory...

high quality submersible pump factory 【high quality submersible pump factory】

Read MoreSlurry Pump

high quality submersible pump factory...

high quality submersible pump factory 【high quality submersible pump factory】

Read MoreExpertise and experience

high quality submersible pump factory...

high quality submersible pump factory 【high quality submersible pump factory】

Read More

Popular articles

- Step 4

- Step 3

- How Slurry Pumps Differ From Standard Pumps?

- Slurries are divided into two main categories: non-settling or settling. Non-settling slurries consist of very fine particles, giving the illusion of increased apparent viscosity. These slurries usually have low wear characteristics, but require very careful consideration when selecting the right pump, as they behave differently from ordinary liquids.

- >Dredge Pump

- Longer maintenance intervals

Latest articles

-

Particle size, shape and hardness (impact on wear and corrosion potential of pump components)

-

Slurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

-

Slurry pump seals

-

In this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

-

Follow proper piping principles to ensure consistent and uniform delivery of mud to the pump.

-

>Dredge Pump

Links

- On the technological frontier, titanium dioxide’s ability to interact with light has seen it being explored for use in solar cells and sensors. Nanotechnology is pushing the boundaries of what was once considered just a pigment, suggesting that TiO2 could hold the key to more efficient energy conversion processes in the future.

- 5. Drying and calcination The wet titanium dioxide is dried to remove any remaining moisture and then calcined at high temperatures to remove any organic or inorganic impurities and to sinter the particles together.

- One of the key factors to consider when looking for a titanium oxide manufacturer is the quality of their product. It is important to work with a manufacturer that produces high-quality titanium oxide that meets industry standards. This ensures that the product will perform effectively in its intended application and provide the desired results.

- Manufacturers and suppliers specializing in titanium dioxide coatings play a crucial role in delivering these benefits to end-users. They ensure that the titanium dioxide is of high purity, uniformly dispersed, and properly formulated to meet specific application needs. The expertise of these suppliers is paramount in developing coatings that not only protect substrates but also enhance their aesthetic appeal.

The produced barium sulfide enters the leacher, and the temperature is controlled above 65°C to obtain a barium sulfide content of 70%, and then enters the clarification barrel, add zinc sulfate for reaction after clarification, control the zinc sulfate content to be greater than 28%, pH=8~9, and obtain a mixture of barium sulfate and zinc sulfide with a density of 1.296~1.357 g/cm3.

Packing:

North America

The FDA categorized titanium dioxide as “Generally Recognized as Safe,” but there are warnings about its potential dangers from other organizations.

Description:

The ingredient in question? Titanium dioxide.

Breathing problems in offspring

If you have a different topic or need assistance with another subject, please let me know and I would be happy to help If you have a different topic or need assistance with another subject, please let me know and I would be happy to help

If you have a different topic or need assistance with another subject, please let me know and I would be happy to help If you have a different topic or need assistance with another subject, please let me know and I would be happy to help china c1 77891.

china c1 77891.

Free Samples Titanium Dioxide/TiO2/Titanium Oxide Price

How do I know if a Unilever product contains titanium dioxide?

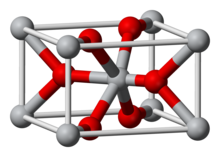

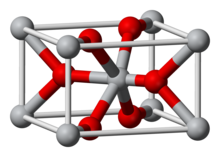

Composition

Cosmetics

Moreover, energy consumption is optimized through innovative procedures and equipment, aligning with sustainability goals Moreover, energy consumption is optimized through innovative procedures and equipment, aligning with sustainability goals

Moreover, energy consumption is optimized through innovative procedures and equipment, aligning with sustainability goals Moreover, energy consumption is optimized through innovative procedures and equipment, aligning with sustainability goals rutile titanium dioxide factories.

rutile titanium dioxide factories.Barium sulfide is produced by carbothermic reduction of barium sulfate. Zinc sulfate is obtained from a variety of zinc products, often waste, by treatment with sulfuric acid.

It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality

It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality