high quality slurry pump for wet blasting suppliers

Latest articles

If you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

high quality slurry pump for wet blasting suppliers...

high quality slurry pump for wet blasting suppliers 【high quality slurry pump for wet blasting suppliers】

Read MoreIf pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

high quality slurry pump for wet blasting suppliers...

high quality slurry pump for wet blasting suppliers 【high quality slurry pump for wet blasting suppliers】

Read More>Dredge Pump

high quality slurry pump for wet blasting suppliers...

high quality slurry pump for wet blasting suppliers 【high quality slurry pump for wet blasting suppliers】

Read MoreWhat we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. , Slurry pumps, are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

high quality slurry pump for wet blasting suppliers...

high quality slurry pump for wet blasting suppliers 【high quality slurry pump for wet blasting suppliers】

Read MoreIn harsh conditions with sand, sludge, rocks and mud, ordinary slurry pumps tend to clog, wear and fail frequently. But WA heavy duty slurry pumps are highly resistant to wear and corrosion, which means that the service life of our slurry pumps is better than other manufacturers' pumps.

high quality slurry pump for wet blasting suppliers...

high quality slurry pump for wet blasting suppliers 【high quality slurry pump for wet blasting suppliers】

Read MoreDry Installation

high quality slurry pump for wet blasting suppliers...

high quality slurry pump for wet blasting suppliers 【high quality slurry pump for wet blasting suppliers】

Read MoreA , slurry pump, is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

high quality slurry pump for wet blasting suppliers...

high quality slurry pump for wet blasting suppliers 【high quality slurry pump for wet blasting suppliers】

Read More>Dredge Pump

high quality slurry pump for wet blasting suppliers...

high quality slurry pump for wet blasting suppliers 【high quality slurry pump for wet blasting suppliers】

Read MoreWhen flushing is required, the >slurry pump supplier recommends the API Option 32 sealed pipe arrangement as it is more suitable for services containing solids or contaminants that could damage the seal faces if recirculated in the flushing medium.

high quality slurry pump for wet blasting suppliers...

high quality slurry pump for wet blasting suppliers 【high quality slurry pump for wet blasting suppliers】

Read MoreA >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

high quality slurry pump for wet blasting suppliers...

high quality slurry pump for wet blasting suppliers 【high quality slurry pump for wet blasting suppliers】

Read More

Popular articles

- WA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

- The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. There are many drive modes for option, such as V-belt, flexible coupling, gearbox, hydraulic coupler variable frequency, silicon controlled speed, etc. Among them, the flexible shaft coupling drive and V-belt feature of low cost and easy installation.

- With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of , dredging pumps, is also increasing.

- A target=_blank title=Slurry Pump>slurry pump is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

- For more information about this new and improved pump, please contact us.

- The concept of the >slurry pump and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

Latest articles

-

Rubber is lighter and softer than other wear lining materials. This aids installation because it is easier to lift and install quickly and efficiently. Positive results for the health and safety of workers in the field.

-

Aier is pumping experts and offer some useful tips to maintain your >slurry pump.

-

The slurry pump is mainly used in the mining industry, its wear resistance is strong. So It conveys slurry that containing slag, but it can conveys mud. The mud pump is usually made of cast iron, the wear resistance of the pump is low. So the mud pumps often used for conveying mud or slurry containing suspended particles.

-

The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

-

Dry Installation

-

WA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

Links

Step-by-Step Guide to Adjusting Sliding Door Rollers

- The construction of a steel fireproof safe typically involves multiple layers. The outer layer is made of thick steel plates for strength and burglary resistance. Inside, there are layers of fire-resistant materials such as ceramic wool or vermiculite that can withstand high temperatures for an extended period. This insulation not only keeps the heat out but also maintains a cool internal environment, ensuring the survival of temperature-sensitive items like documents, electronics, and precious metals.

- Another popular design for cast iron fence decorations is the scrollwork pattern. These intricate designs feature delicate curls and swirls that give the fence a more ornate and decorative look. Scrollwork designs can be simple or elaborate, depending on your personal style preference. They can also be customized to include your initials or other personalized details.

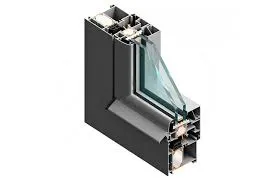

Two are the main types of aluminum window profiles manufactured by Profilati Alluminio, both certified according to the European regulations:

- In addition, many metal security boxes come with additional features like wall mounting capabilities or a portable design, adding to their versatility. Some even integrate with home security systems, providing an extra level of monitoring and alerting you in case of any unauthorized access attempts.

- However, implementing sliding wheel prices is not without its challenges. Retailers must carefully consider factors such as product variability, customer behavior, and market conditions when setting their price limits. They must also be prepared to continuously monitor and adjust their prices in response to changing market conditions and customer feedback.

- Aluminum windows are a popular choice for homeowners due to their durability and low maintenance requirements. However, over time, the rollers that allow the window to slide smoothly can wear out and need to be replaced. In this article, we will discuss the process of aluminum window roller replacement.

- In addition to functionality, sliding mirror doors also offer a touch of elegance and sophistication

- Aesthetics also play a crucial role in the success of pull handles. They come in a wide range of styles, materials, and finishes, allowing designers to match them with any interior design scheme. From classic brass handles to sleek stainless steel pulls, there is a style to suit every taste and preference.

The profile is bent with both hands, and the twisting strength is good, and it can be restored after loosening your hands. If the strength of the aluminium profile is not enough, it is easy to be deformed, which may result in unqualified wind pressure resistance level, the finished switch is not smooth, and the deformation amount is too large.

- Furthermore, industrial hanging door rollers contribute to the overall efficiency and productivity of industrial operations. By providing smooth and effortless movement for heavy sliding doors, these rollers help workers easily access tools, equipment, and materials stored behind the doors. This increased accessibility can save valuable time and improve workflow in industrial settings.

- It can be easier to find detailed, ornate decorations in cast iron than in steel

Application Security is paramount when investing in a fence. In fact, it’s the primary purpose of fencing: to keep your property safe and secure. It keeps pets and children in, and intruders out. As such, this is not something you can overlook in the fencing selection process.

- 9

Adjusting the rollers on sliding doors is a straightforward process that can greatly enhance their functionality. By following the steps outlined above, you can ensure that your sliding door operates smoothly and lasts for many years. Regular maintenance, including cleaning and lubricating, will further ensure optimal performance. With a little time and effort, you can keep your sliding doors in excellent condition and enjoy their benefits throughout your home.

While at it, you should be careful not to overheat it to a melting point, often about 1200° F. An ideal heating point should be approximately 900° F.

Turning the screws clockwise or counterclockwise will either raise or lower the door, helping to correct any imbalance Turning the screws clockwise or counterclockwise will either raise or lower the door, helping to correct any imbalance

Turning the screws clockwise or counterclockwise will either raise or lower the door, helping to correct any imbalance Turning the screws clockwise or counterclockwise will either raise or lower the door, helping to correct any imbalance adjusting sliding doors roller.

adjusting sliding doors roller.Grade

Today, the legacy of head spearing lives on primarily through historical accounts, anthropological studies, and preserved artifacts. Museums showcase these ancient weapons, providing a window into a past where such practices were integral to societal norms. Furthermore, the remnants of head spearing traditions have inspired contemporary art and literature, serving as a reminder of the complex tapestry of human history.

Finally, reinstall the screen door into its frame. Slide the bottom retention clips back into place or screw them back in, and gently lower the door until it clicks into position. Test the door's movement by opening and closing it several times. If it rolls smoothly, congratulations! You've successfully changed your screen door rollers.

Thermal insulation aluminum extruded profiles for doors and windows

3. Design specifications