china submersible pump for slurry factories

Latest articles

Dry Installation

china submersible pump for slurry factories...

china submersible pump for slurry factories 【china submersible pump for slurry factories】

Read MoreA dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

china submersible pump for slurry factories...

china submersible pump for slurry factories 【china submersible pump for slurry factories】

Read MoreTypical Applications of slurry pump

china submersible pump for slurry factories...

china submersible pump for slurry factories 【china submersible pump for slurry factories】

Read More- Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

china submersible pump for slurry factories...

china submersible pump for slurry factories 【china submersible pump for slurry factories】

Read MoreAnother important target=_blank title=Part of the Slurry Pump>part of the slurry pump is its casing, which bears all the pressure. The slurry pump casing should have a large clearance between the impeller and the diversion angle to reduce wear and prevent large solid particles from getting stuck. Due to the extra space, there is more recirculation in the slurry pump casing under various operating conditions. Again, this accelerates wear compared to typical pumps.

china submersible pump for slurry factories...

china submersible pump for slurry factories 【china submersible pump for slurry factories】

Read MoreWhen the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

china submersible pump for slurry factories...

china submersible pump for slurry factories 【china submersible pump for slurry factories】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

china submersible pump for slurry factories...

china submersible pump for slurry factories 【china submersible pump for slurry factories】

Read MoreSlurry pumps can be used to transport mixtures of liquids and solids in many industries in a wide range of applications, such as mine drainage, dredging of sunken lagoons and pumping of drilling mud.

china submersible pump for slurry factories...

china submersible pump for slurry factories 【china submersible pump for slurry factories】

Read MorePumps with replaceable parts and components can have an unlimited service life. A high quality customised slurry pump with replaceable parts can last you a lifetime and should therefore be considered as a very reliable long-term investment.

china submersible pump for slurry factories...

china submersible pump for slurry factories 【china submersible pump for slurry factories】

Read MoreUnder ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

china submersible pump for slurry factories...

china submersible pump for slurry factories 【china submersible pump for slurry factories】

Read More

Popular articles

- Slurry Pump

- >Slurry Pump

- Lifetime use

- WZ series slurry pumps are developed on the wide adaption of both home and abroad advance technology and many years of slurry pump design and field operation experiences.

- Fine-grained sand can be extremely abrasive and typically wears slurry pumps quickly. Characteristics of coarse aggregates that can affect pump performance are size, shape and surface texture, as well as gradual changes in particle size, while fine materials can create excessive friction in the pipe.

- >TL FGD Pump

Latest articles

Links

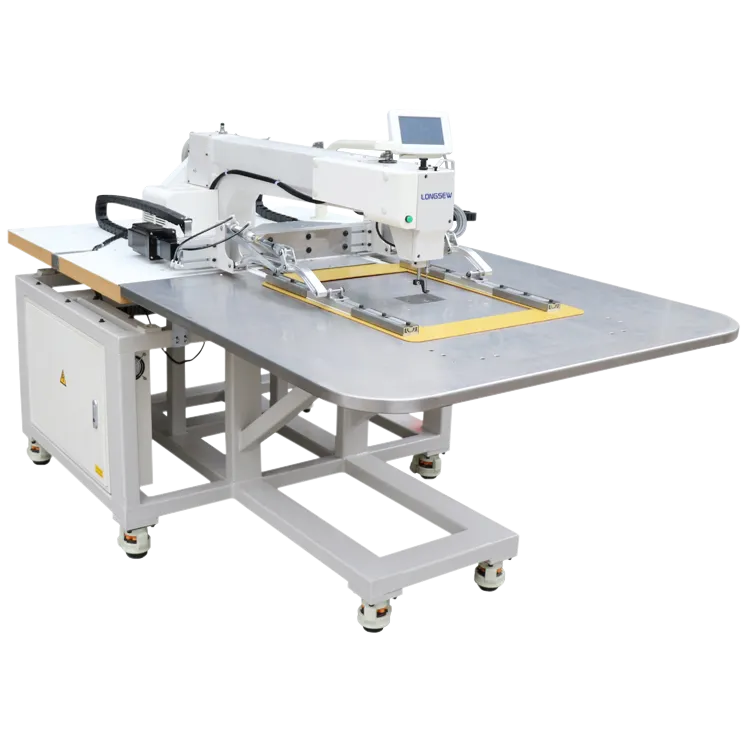

Sewing is a rewarding skill that allows you to create beautiful garments, home décor, and other handmade items. Whether you're looking to mend an old piece of clothing or create something new, understanding the basic sewing instructions is essential. This guide will introduce you to the fundamental techniques that every beginner should know.

In machine sewing, understanding the tension settings is crucial for achieving the perfect stitch. Improper tension can lead to puckering or loose stitches, detracting from the intended design. By experimenting with different settings and practicing on fabric scraps, sewists can enhance their skills and ensure their work remains immaculate.

In conclusion, cylindrical bed sewing machines play an integral role in the textile manufacturing process, offering unmatched versatility and efficiency for tubular sewing applications. Their ability to handle complex shapes and provide high-quality finishes makes them indispensable in the production of modern garments. With continuous advancements in technology and design, these machines are likely to evolve further, enhancing productivity and quality in the sewing industry. As manufacturers seek to streamline operations and respond to market demands, investing in cylindrical bed sewing machines will undoubtedly remain a wise choice for achieving excellence in garment production.

Finishing Touches

When it comes to personalizing and maintaining the interior of your vehicle, one of the most prominent aspects is the car seat covers. Not only do they enhance the aesthetic appeal of your car’s interior, but they also provide protection against wear and tear, spills, and stains. If you're considering a DIY project, a sewing machine dedicated to car seat covers can be an incredibly useful investment. Here, we will explore the importance of choosing the right sewing machine, the materials you’ll need, and some tips to create a perfect car seat cover.

- In addition, these machines often come with specialized presser feet and attachments that help to guide the leather through the machine smoothly and accurately. This is important for maintaining even stitching and preventing mistakes that can ruin the overall look of the bag.