submersible pump suppliers

Latest articles

To reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

submersible pump suppliers...

submersible pump suppliers 【submersible pump suppliers】

Read MoreThe discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. There are many drive modes for option, such as V-belt, flexible coupling, gearbox, hydraulic coupler variable frequency, silicon controlled speed, etc. Among them, the flexible shaft coupling drive and V-belt feature of low cost and easy installation.

submersible pump suppliers...

submersible pump suppliers 【submersible pump suppliers】

Read MoreWhat style of pump is suitable?

submersible pump suppliers...

submersible pump suppliers 【submersible pump suppliers】

Read MoreSlurry pumps can be used for.

submersible pump suppliers...

submersible pump suppliers 【submersible pump suppliers】

Read MoreThe winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

submersible pump suppliers...

submersible pump suppliers 【submersible pump suppliers】

Read MoreDetermine the size of the pump

submersible pump suppliers...

submersible pump suppliers 【submersible pump suppliers】

Read MoreSlurry pumps can also simply axially adjust the clearance between the impeller and the adjacent throat casing sealing surface. This helps to maintain pump performance when internal components begin to wear.

submersible pump suppliers...

submersible pump suppliers 【submersible pump suppliers】

Read MoreIdeal for slurry pumps - Only rubber lined pumps combine strength and corrosion resistance to create a quality slurry pump.

submersible pump suppliers...

submersible pump suppliers 【submersible pump suppliers】

Read MoreFor certain types of slurry pumping conditions, positive displacement pumps may be a more suitable option than centrifugal pumps.

submersible pump suppliers...

submersible pump suppliers 【submersible pump suppliers】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

submersible pump suppliers...

submersible pump suppliers 【submersible pump suppliers】

Read More

Popular articles

Latest articles

-

The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

-

The most important thing here is to determine the pump power required to deliver a specific fluid flow at the desired or required differential pressure. Consider the following.

-

Compared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

-

Corrosiveness of the liquid or slurry mixture: More corrosive slurries will wear pump components faster and may dictate the choice of pump manufacturing materials.

-

The terms slurry pump and dredge pump can be used interchangeably.

-

In a subsea installation, the slurry pump runs directly in the slurry and does not require a support structure, which means it is flexible and easy to install. If possible, the catch basin should be equipped with sloping walls to allow sediment to slide down into the area directly below the pump inlet. Agitators should be used when the liquid contains large amounts of solids and has a high particle density. Freestanding or side-mounted (submersible) mixers are an excellent choice for resuspended solids, especially if the catch basin is large or does not have sloping walls.

Links

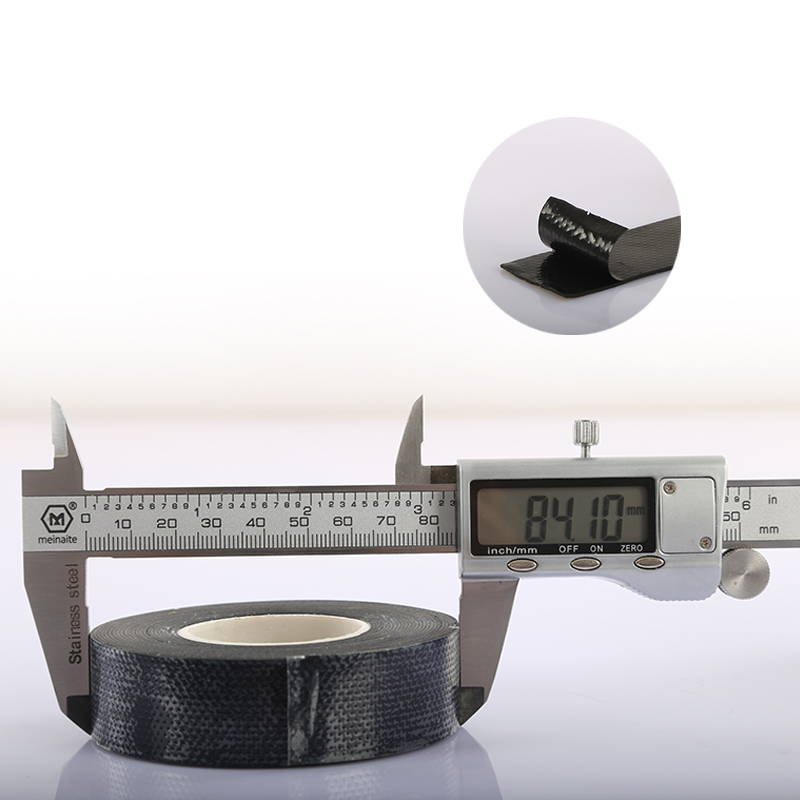

What is electrical tape?

The bright colors and bold patterns used in most floor tapes also add a touch of personality and style to any space, making them an attractive addition to any décor The bright colors and bold patterns used in most floor tapes also add a touch of personality and style to any space, making them an attractive addition to any décor

The bright colors and bold patterns used in most floor tapes also add a touch of personality and style to any space, making them an attractive addition to any décor The bright colors and bold patterns used in most floor tapes also add a touch of personality and style to any space, making them an attractive addition to any décor