metso slurry pump manufacturers

Latest articles

Keep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

metso slurry pump manufacturers...

metso slurry pump manufacturers 【metso slurry pump manufacturers】

Read MoreEspecially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

metso slurry pump manufacturers...

metso slurry pump manufacturers 【metso slurry pump manufacturers】

Read MoreHow does a dredge pump work?

metso slurry pump manufacturers...

metso slurry pump manufacturers 【metso slurry pump manufacturers】

Read MoreBCT Ceramic Slurry Pumps

metso slurry pump manufacturers...

metso slurry pump manufacturers 【metso slurry pump manufacturers】

Read MoreWill solids size pass through the pump?

metso slurry pump manufacturers...

metso slurry pump manufacturers 【metso slurry pump manufacturers】

Read MoreCustomised solutions

metso slurry pump manufacturers...

metso slurry pump manufacturers 【metso slurry pump manufacturers】

Read MorePumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.

metso slurry pump manufacturers...

metso slurry pump manufacturers 【metso slurry pump manufacturers】

Read MorePump selection for FGD

metso slurry pump manufacturers...

metso slurry pump manufacturers 【metso slurry pump manufacturers】

Read MoreExpertise and experience

metso slurry pump manufacturers...

metso slurry pump manufacturers 【metso slurry pump manufacturers】

Read MoreThe impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

metso slurry pump manufacturers...

metso slurry pump manufacturers 【metso slurry pump manufacturers】

Read More

Popular articles

- Dredge pumps are designed to transfer large quantities of fluids and solids.

- Dredge Pump Features

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- Slurry Pump Selection

- Improved flow control

- Includes a large number of solids or particles.

Latest articles

-

>Slurry Pump

-

Submersible slurry pump pumps offer many advantages over dry and semi-dry (cantilever) mounted pumps.

-

A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right , pump, .xa0, In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

-

As new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumpsxa0help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

-

Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

-

If you've ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. There's no doubt that the slurry on the pump is hard. But the more you know about what's being pumped, the better your pump selection will be, resulting in longer mean time between failures. Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share the following content with you.

Links

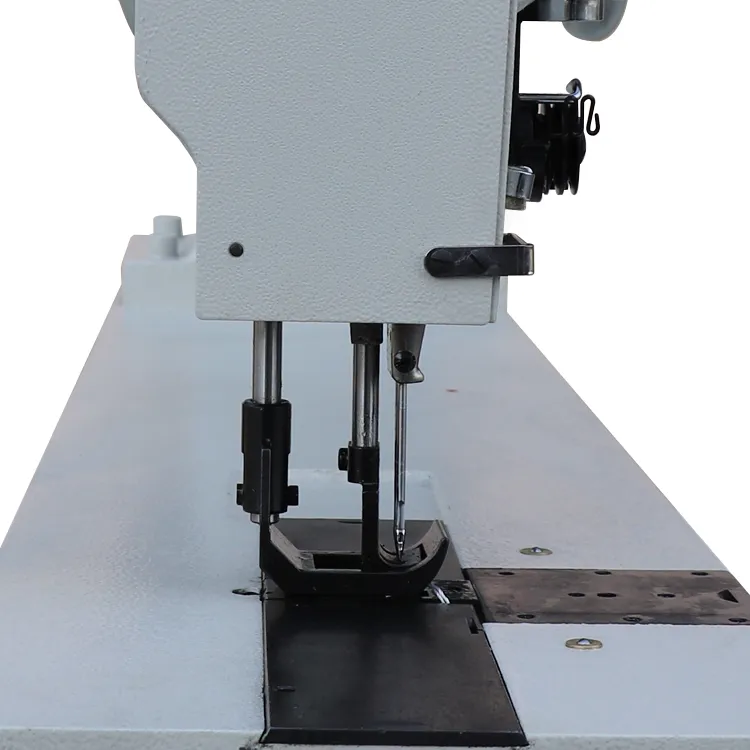

1. Heavy-Duty Construction When selecting a sewing machine for fur and leather, it’s critical to choose one with a robust and durable build. These materials require a machine that can withstand the pressures of thick layers without skipping stitches or breaking needles. A heavy-duty machine will also provide better stability, reducing the chance of puckering.

2. Powerful Motor A heavy duty sewing machine is typically equipped with a strong motor that provides the necessary torque for tackling tough fabrics. This prevents the machine from slowing down or stalling, allowing for a seamless sewing experience.

Furthermore, an automatic needle threader can enhance the versatility of sewing machines

. Many modern machines equipped with this technology also come with advanced features such as multiple stitch options, embroidery capabilities, and adjustable speed controls. This combination allows for a more comprehensive sewing experience, where users can explore various projects, from simple repairs to intricate designs, all while benefiting from the ease of automatic threading.The needle and feeding mechanism are also tailored for leather. Strong needles capable of piercing through multiple layers of tough material and specialized feed dogs that grip the leather firmly while avoiding damage make these machines incredibly effective. Additionally, many models come equipped with adjustable presser feet to accommodate different thicknesses of leather, allowing for versatility in sewing various projects.