china wastewater treatment centrifugal pump manufacturer

Latest articles

Corrosiveness of the liquid or slurry mixture: More corrosive slurries will wear pump components faster and may dictate the choice of pump manufacturing materials.

china wastewater treatment centrifugal pump manufacturer...

china wastewater treatment centrifugal pump manufacturer 【china wastewater treatment centrifugal pump manufacturer】

Read MoreAuxiliary equipment

china wastewater treatment centrifugal pump manufacturer...

china wastewater treatment centrifugal pump manufacturer 【china wastewater treatment centrifugal pump manufacturer】

Read MoreIncludes a large number of solids or particles.

china wastewater treatment centrifugal pump manufacturer...

china wastewater treatment centrifugal pump manufacturer 【china wastewater treatment centrifugal pump manufacturer】

Read MoreIf pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

china wastewater treatment centrifugal pump manufacturer...

china wastewater treatment centrifugal pump manufacturer 【china wastewater treatment centrifugal pump manufacturer】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

china wastewater treatment centrifugal pump manufacturer...

china wastewater treatment centrifugal pump manufacturer 【china wastewater treatment centrifugal pump manufacturer】

Read MoreTraditionally, centrifugal pumps are used to pump highly abrasive slurries. Centrifugal pumps use the force generated by the rotating impeller to impinge kinetic energy into the slurry.

china wastewater treatment centrifugal pump manufacturer...

china wastewater treatment centrifugal pump manufacturer 【china wastewater treatment centrifugal pump manufacturer】

Read MoreAll products are mainly supplied to environmental protection, wastewater treatment, urban water supply and drainage, mine, metallurgy, coal, petrochemical, building material, thermal power FGD, river dredging, tailing disposal and other fields.

china wastewater treatment centrifugal pump manufacturer...

china wastewater treatment centrifugal pump manufacturer 【china wastewater treatment centrifugal pump manufacturer】

Read MoreNatural rubber is an excellent wear material when handling wet sand slurries. Its strength, resilience and cut resistance have a positive impact on the wear performance of slurry pumps.

china wastewater treatment centrifugal pump manufacturer...

china wastewater treatment centrifugal pump manufacturer 【china wastewater treatment centrifugal pump manufacturer】

Read MoreIt is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

china wastewater treatment centrifugal pump manufacturer...

china wastewater treatment centrifugal pump manufacturer 【china wastewater treatment centrifugal pump manufacturer】

Read MoreA typical pump solution for this application is to install a hard metal >slurry pump to withstand these types of conditions. Hard metal pumps need to be able to withstand the most severe abrasive slurry service and they also need to be designed to be extremely easy to maintain and safe.

china wastewater treatment centrifugal pump manufacturer...

china wastewater treatment centrifugal pump manufacturer 【china wastewater treatment centrifugal pump manufacturer】

Read More

Popular articles

- Slurry Pump

- One problem with centrifugal pumps is that the velocity and shear forces within the pump may damage the slurry/solids. Typically, twin-screw pumps cause the least damage to solids in the slurry.

- Slurry pipe diameter.

- Fine-grained sand can be extremely abrasive and typically wears slurry pumps quickly. Characteristics of coarse aggregates that can affect pump performance are size, shape and surface texture, as well as gradual changes in particle size, while fine materials can create excessive friction in the pipe.

- All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

- Slurry Pump

Latest articles

-

Our firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

-

A clear clean fluid supplied from an external source is normally used which is delivered to the main sealing surface on the fluid side of the sealing process. By using a closed gap throat bushing, the stuffing box can be back-pressurised to a higher pressure, ensuring that the flushing fluid does not flash across the seal face.

-

Consider the pump components

-

As new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumpsxa0help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

-

Choosing the Right Pump for Flue Gas Desulphurisation

-

In dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

Links

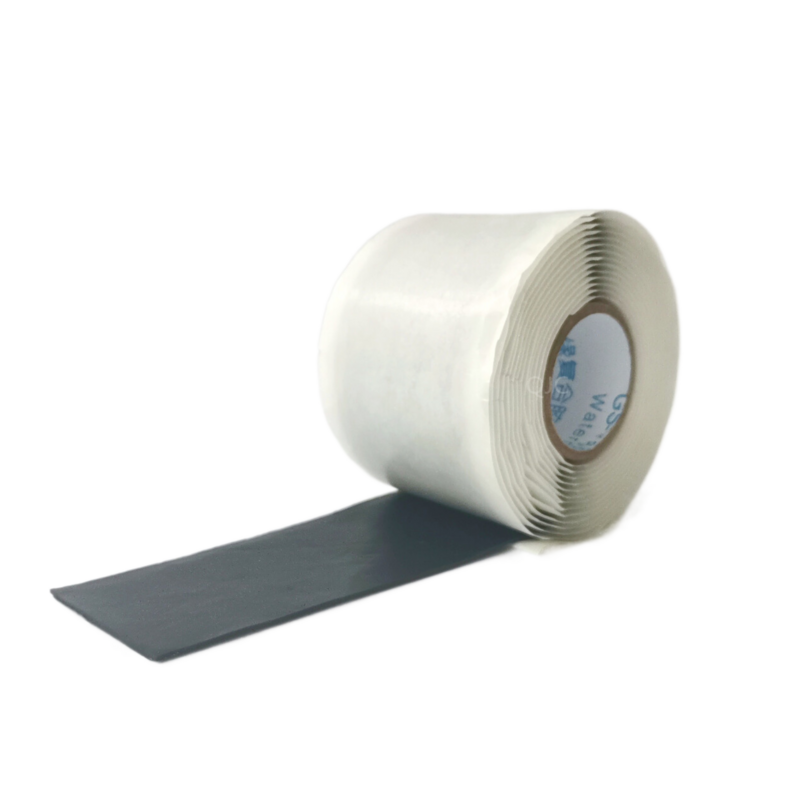

If you’re unfamiliar with reasons why people use electrical tape over other more basic tapes, there are a few factors that make it stand out among the rest:

Electrical tape is made from a variety of materials, including PVC, rubber, and cloth. Each type of material has different heat-resistant properties.

- Moreover, the 4 x 5 size is perfectly designed for a range of tasks

- 1. Electrical insulation Black insulation tape is commonly used to insulate wires, cables, and joints to prevent electrical shorts and improve electrical safety.

- In conclusion, automotive fabric tapes are a versatile and cost-effective solution for a wide range of automotive applications. Their durability, resistance to harsh environmental conditions, and ability to provide excellent adhesion make them an indispensable tool for manufacturers and suppliers looking to enhance the quality and performance of their vehicles. As the demand for high-quality, reliable automotive components continues to grow, the use of automotive fabric tapes is likely to increase in the years ahead.

- 3. Anti-Slip Tape This tape is designed to provide extra traction on slippery surfaces, reducing the risk of slips and falls. It is commonly used in areas with high foot traffic, such as stairways, ramps, and walkways.

- Automotive cloth tape, also known as automotive grade cloth tape or fabric tape, is an essential component in the world of vehicle manufacturing and maintenance. This specialized adhesive tape, with its robust design and versatile applications, has become a staple in the automotive industry due to its ability to withstand extreme conditions and provide reliable performance.

- In conclusion, the humble rubber strip for door seals is far more than a mere accessory; it is a critical component that ensures our doors perform at their best. By providing insulation, soundproofing, and protection from the elements, these strips play a pivotal role in enhancing the comfort, efficiency, and beauty of our homes. Investing in quality rubber strips and installing them correctly is a small step that yields significant rewards, transforming the entrance to our abodes into a secure and welcoming barrier against the outside world.

Its ability to adhere to various materials, including metal, glass, and plastic, makes it a preferred choice for car manufacturers Its ability to adhere to various materials, including metal, glass, and plastic, makes it a preferred choice for car manufacturers

Its ability to adhere to various materials, including metal, glass, and plastic, makes it a preferred choice for car manufacturers Its ability to adhere to various materials, including metal, glass, and plastic, makes it a preferred choice for car manufacturers