high quality vertical sump pump rubber lined factories

Latest articles

Determine the size of the pump

high quality vertical sump pump rubber lined factories...

high quality vertical sump pump rubber lined factories 【high quality vertical sump pump rubber lined factories】

Read MoreWL Series Light-duty pumps are cantilevered, horizontal centrifugal slurry pumps. They are suitable for delivering low density slurries for metallurgical, mining, coal and building material departments. The shaft seal adopts both gland seal and centrifugal seal.

high quality vertical sump pump rubber lined factories...

high quality vertical sump pump rubber lined factories 【high quality vertical sump pump rubber lined factories】

Read MoreAll products are mainly supplied to environmental protection, wastewater treatment, urban water supply and drainage, mine, metallurgy, coal, petrochemical, building material, thermal power FGD, river dredging, tailing disposal and other fields.

high quality vertical sump pump rubber lined factories...

high quality vertical sump pump rubber lined factories 【high quality vertical sump pump rubber lined factories】

Read MoreDredge Pump

high quality vertical sump pump rubber lined factories...

high quality vertical sump pump rubber lined factories 【high quality vertical sump pump rubber lined factories】

Read MoreAgain, to meet life cycle cost considerations, pumps should be equipped with large diameter impellers for lower operating speeds and longer wear life, as well as field replaceable rubber liners that can be bolted on for quick maintenance. In a typical coal-fired power plant, two to five pumps will be used in each spray tower.

high quality vertical sump pump rubber lined factories...

high quality vertical sump pump rubber lined factories 【high quality vertical sump pump rubber lined factories】

Read MoreThere are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

high quality vertical sump pump rubber lined factories...

high quality vertical sump pump rubber lined factories 【high quality vertical sump pump rubber lined factories】

Read MoreCorrosiveness of the slurry

high quality vertical sump pump rubber lined factories...

high quality vertical sump pump rubber lined factories 【high quality vertical sump pump rubber lined factories】

Read MoreSlurry Pump

high quality vertical sump pump rubber lined factories...

high quality vertical sump pump rubber lined factories 【high quality vertical sump pump rubber lined factories】

Read MoreAdapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

high quality vertical sump pump rubber lined factories...

high quality vertical sump pump rubber lined factories 【high quality vertical sump pump rubber lined factories】

Read MoreWe know that the right rubber and ceramic liners work very well. They also last longer and can withstand more demanding use. They can also be replaced, thereby extending the life of the pump while reducing operating costs. You can also customise your pump with a variety of ceramic parts, including bushings, pump housings, impellers, wet ends and even seals.

high quality vertical sump pump rubber lined factories...

high quality vertical sump pump rubber lined factories 【high quality vertical sump pump rubber lined factories】

Read More

Popular articles

- Lifetime use

- Especially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

- - Installation flexibility - The submersible slurry pump is available in a variety of mounting models, including portable and semi-permanent (also easy to move as it can be freely suspended from a chain or similar device without having to be bolted to the ground/floor, etc.).

- Sites often rely on centrifugal pumps to provide slurry service. These pumps (and their associated piping systems) require special provisions that demand detailed knowledge of the properties of solids and slurries to prevent wear, corrosion, erosion and other adverse effects such as solids settling. Specifying the optimum combination of speed, geometry and material requires a proper balance of often conflicting pump priorities; this requires consideration of stable operation, maximum wear life, operational flexibility and minimum energy consumption.

- Slurry Pump Impeller Type

- Our firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

Latest articles

-

These conditions include

-

Why would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

-

Another way of classifying the type of slurry pump installation is dry installation or wet installation. Dry installation pumps have the hydraulic end and drive located outside the liquid, whereas wet installation pumps (such as submersible pumps) operate within a catch basin or slurry. Submersible pumps do not require much support structure and therefore do not take up much space. Depending on the type of operation and installation required, the preferred method of pump installation is determined.

-

Determine the operating parameters of the pump.

-

Slurry Pump

-

The concept of the , slurry pump, and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

Links

- One of the main advantages of bed sheet corner straps is that they help to ensure a smooth and wrinkle-free sleeping surface. When your fitted sheet stays in place, it means that the fabric remains taut and flat, with no bunching or creases to disrupt your sleep. This can make for a more comfortable and restful night's sleep, as you won't have to constantly readjust your bedding to get it just right.

- In conclusion, the plain duvet insert is a testament to the power of simplicity in home decor. Its adaptable nature, coupled with its ability to provide warmth and comfort, makes it a must-have for any bedroom. When choosing the perfect insert, remember to consider factors like material, fill power, and ease of care. With the right choice, you'll enjoy a restful slumber, enveloped in the timeless charm of your plain duvet insert.

Furthermore, their quick-drying property reduces the energy needed for drying, decreasing the carbon footprint associated with laundry Furthermore, their quick-drying property reduces the energy needed for drying, decreasing the carbon footprint associated with laundry

Furthermore, their quick-drying property reduces the energy needed for drying, decreasing the carbon footprint associated with laundry Furthermore, their quick-drying property reduces the energy needed for drying, decreasing the carbon footprint associated with laundry thin towels.

thin towels.

pure essentials sheets. The natural fibers used in these sheets are biodegradable and renewable, making them a greener alternative to synthetic bedding materials. By choosing pure essentials sheets, you can reduce your carbon footprint and support more sustainable practices in the textile industry.

Medium Size Towels

Sleeping Pillow

When choosing bedsheets, it is important to consider factors such as material, weave, thread count, and care instructions. If softness and warmth are your priority, flannel sheets may be your best choice. For a silky, luxurious feel, satin or satin sheets may be the perfect choice. If breathability and durability are your top priorities, cotton sheets may best suit your needs.

When it comes to comfort, the type of bed sheets and pillowcases you choose can make a big difference. Choose high-quality bed sheets made from materials like Egyptian cotton or bamboo for a soft, breathable feel. Adding a bed pad can also increase the comfort of your mattress and provide an extra layer of cushioning.

A coverlet is a decorative fabric covering that does not touch the floor and normally does not cover the pillows. Woven coverlets and quilts fall into this category. These are normally bed accents and they can sit on top of bedspreads. If you think of hotel room bedding, these can also be found at the foot of the bed used like foot runners.

Solid designs are a fantastic choice if you already have a detailed bedroom décor and only want to add a burst of color to the area. If you want a duvet cover that will be used to decorate the entire bedroom, intricate designs such as branches, flowers, and stripes may be desirable. The use of embellishments like pleats add visual interest. Some duvet covers are reversible, featuring a distinct pattern on either side of the cover. Reversible duvet covers allow you to change the look of your bedroom quickly and easily without having to buy additional bedding pieces.

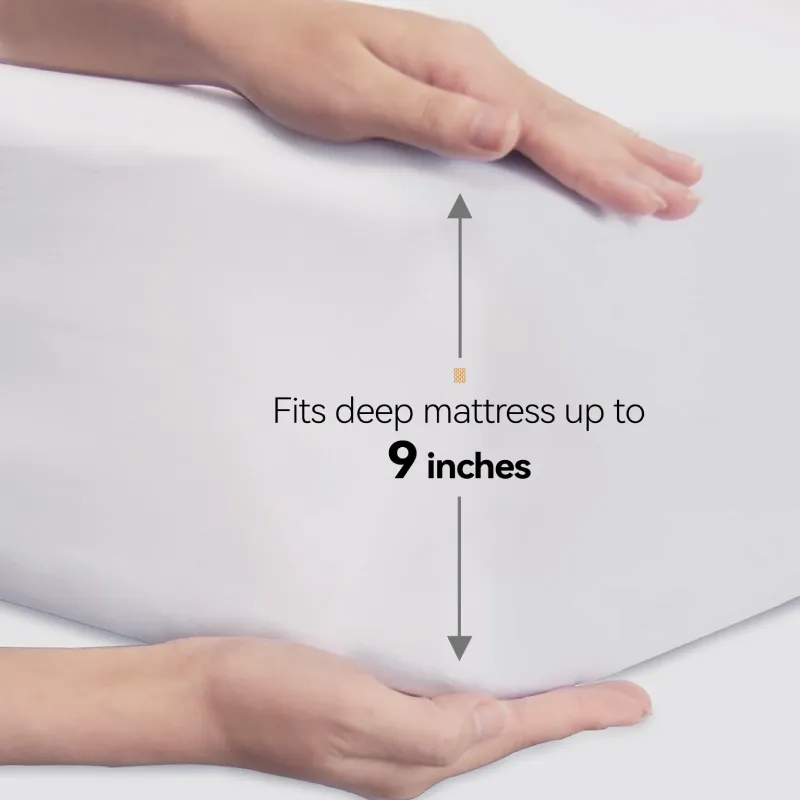

These sheets are normally flat and need to be tucked around the corners of the mattress to keep them in place during sleeping.