open impeller slurry pump manufacturer

Latest articles

Choosing the right pump for your slurry is critical to getting the most out of it. Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear caused by abrasive slurries. Compared to low-viscosity liquid pumps, target=_blank title=Slurry Pump>slurry pumps are typically larger and often require more horsepower to operate because they are less efficient. Bearings and shafts must also be more robust and durable.

open impeller slurry pump manufacturer...

open impeller slurry pump manufacturer 【open impeller slurry pump manufacturer】

Read MoreSafety

open impeller slurry pump manufacturer...

open impeller slurry pump manufacturer 【open impeller slurry pump manufacturer】

Read More- Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

open impeller slurry pump manufacturer...

open impeller slurry pump manufacturer 【open impeller slurry pump manufacturer】

Read MoreAll manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

open impeller slurry pump manufacturer...

open impeller slurry pump manufacturer 【open impeller slurry pump manufacturer】

Read MoreIt is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

open impeller slurry pump manufacturer...

open impeller slurry pump manufacturer 【open impeller slurry pump manufacturer】

Read MoreTypes of slurry pump installation.

open impeller slurry pump manufacturer...

open impeller slurry pump manufacturer 【open impeller slurry pump manufacturer】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of , dredging pumps, is also increasing.

open impeller slurry pump manufacturer...

open impeller slurry pump manufacturer 【open impeller slurry pump manufacturer】

Read MoreMaterials of Construction

open impeller slurry pump manufacturer...

open impeller slurry pump manufacturer 【open impeller slurry pump manufacturer】

Read More- Portable and low maintenance - There are no long or exposed mechanical shafts between the motor and worm gear, which makes the submersible pump more portable. In addition, because there are no long or exposed mechanical connections between the motor and worm gear, less maintenance is required and operating costs are significantly lower.

open impeller slurry pump manufacturer...

open impeller slurry pump manufacturer 【open impeller slurry pump manufacturer】

Read MoreTL FGD Pump

open impeller slurry pump manufacturer...

open impeller slurry pump manufacturer 【open impeller slurry pump manufacturer】

Read More

Popular articles

- Slurry pipe diameter.

- Aier is pumping experts and offer some useful tips to maintain your >slurry pump.

- What is the pump constructed of?

- Determine the nature of the material to be pumped

- Settling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

- Choosing the right pump for your slurry is critical to getting the most out of it. Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear caused by abrasive slurries. Compared to low-viscosity liquid pumps, target=_blank title=Slurry Pump>slurry pumps are typically larger and often require more horsepower to operate because they are less efficient. Bearings and shafts must also be more robust and durable.

Latest articles

-

Pumping slurry can be a challenging problem, but with the right instruction, pumping and maintenance plan, you will achieve operational success.

-

Dredge Pump

-

There is a better way to pump sewage, overflows and other collected dirty water around the plant.

-

The design of the slurry pump is critical to ensure that the abrasive and often corrosive aspects of the slurry do not damage the impeller. In addition, slurries and sludges may contain large amounts of unforeseen solids, which will inevitably clog many types of pumps. Since most centrifugal pump impellers have very tight tolerances on the worm gear, the abrasive (and sometimes corrosive) nature of the slurry will quickly wear down the worm gear and destroy the tolerances. In turn, this causes the pump to lose suction. This can lead to extensive downtime of the slurry pump, as well as expensive maintenance and spare parts.

-

Compared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

-

The frame plate for WAJ series pumps has interchangeable hard metal or pressure moulded elastomer liners. The impellers are made of pressure moulded elastomer liners.The shaft seals for WAJ series can be packing seal, centrifugal seal or mechanical seal.

Links

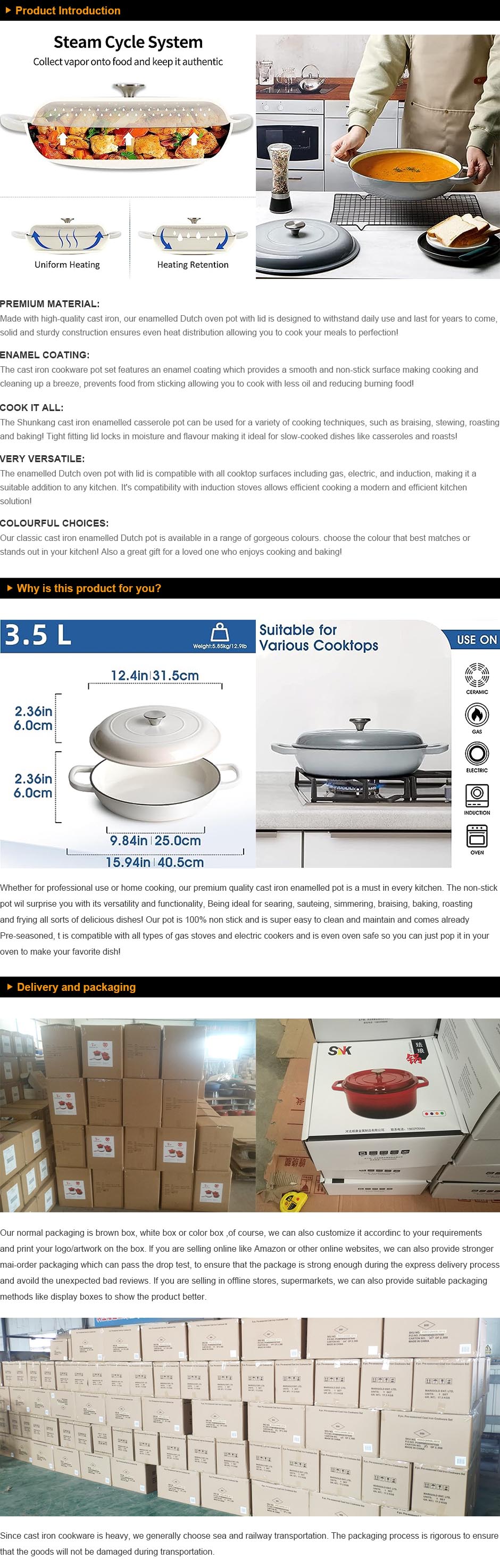

- The unique properties of a cast iron skillet set it apart from other cookware. With its ability to retain heat evenly, it ensures that your dishes cook consistently, from searing a perfect steak to simmering a rich, flavorful stew. It's equally adept at low-and-slow cooking or high-temperature searing, making it suitable for a wide range of recipes. Moreover, it's compatible with various heat sources, including stovetops, ovens, and even campfires, allowing you to bring the joy of cast iron cooking wherever you go.

- **Introduction

- Another advantage of the black iron frying pan is its even heat distribution. The thick bottom and heavy construction ensure that heat is distributed evenly across the entire surface of the pan, preventing hot spots from forming and ensuring that your food cooks evenly from edge to edge. This is especially important when cooking delicate items like eggs or fish, where even cooking is crucial for achieving the desired texture and flavor.

- The Timeless Charm of Cast Iron Outdoor Grill Pans

Large Enamel Pots With Lids

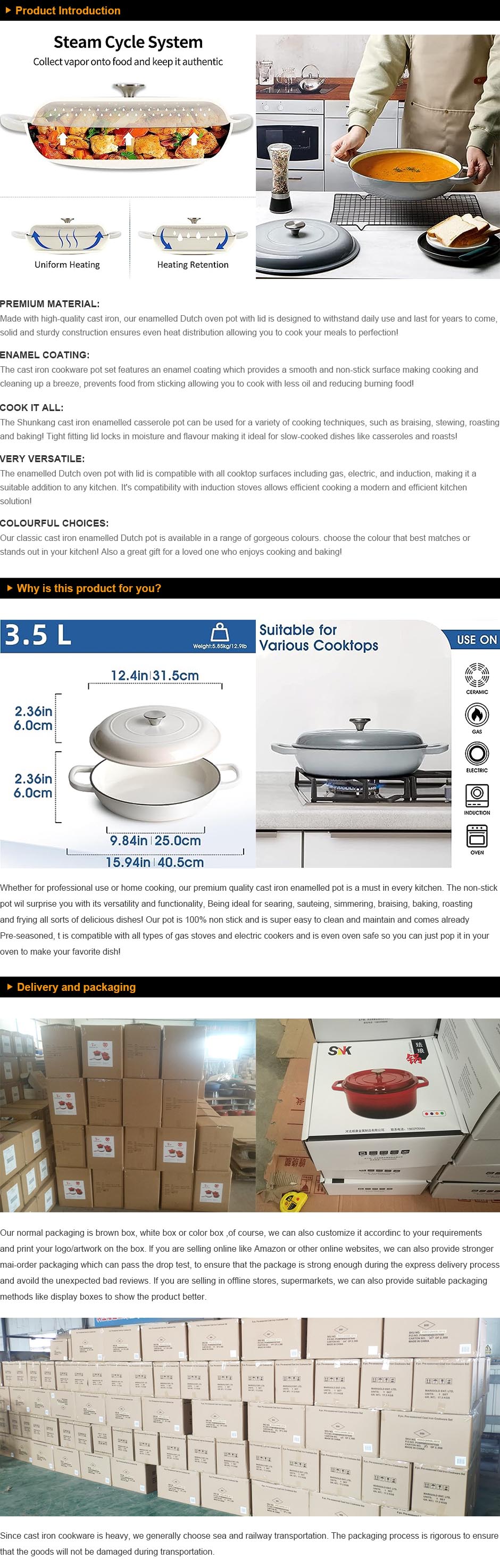

red enamel cookware. Red enamel cookware can complement any kitchen decor, whether it be modern, farmhouse, or eclectic. It can also be a great gift for cooking enthusiasts who appreciate both fashion and function in their cookware.

Another thing to keep in mind when shopping for a pan is the amount of space you have available. If you have a farmhouse kitchen with ample drawer space and a pot rack, for example, you can justify picking up one (or more) of each. For more compact kitchens, however, a smaller multi-material set will allow you to do a lot with a little.

It's also perfect for making international favorites like crepes, dosas, or even Korean BBQ-style meals It's also perfect for making international favorites like crepes, dosas, or even Korean BBQ-style meals

It's also perfect for making international favorites like crepes, dosas, or even Korean BBQ-style meals It's also perfect for making international favorites like crepes, dosas, or even Korean BBQ-style meals two sided griddle.

two sided griddle.Cast Iron: Traditional cast iron Dutch ovens are renowned for their excellent heat retention and durability. They are ideal for slow cooking, braising, and baking, and can be used on stovetops and in ovens.

Whether you're looking for classic white enamel cookware or colorful enamel pots to add a pop of personality to your kitchen, enamel cookware cooking pots are a versatile and practical choice. With their durability, ease of maintenance, and variety of colors, the enamelware cooking pot is sure to be a much-loved addition to your kitchen for years to come.

ARE SKILLETS AND FRYING PANS THE SAME?

However, there’s no need to worry because we’re here to help you. French skillets have recently gained popularity in American kitchens, but many people are unfamiliar with them. After all, a pan is a pan, right?

Cast Iron Griddle For Grill

Its heavy construction helps maintain a consistent temperature, which is particularly beneficial for dishes that require low-and-slow cooking methods Its heavy construction helps maintain a consistent temperature, which is particularly beneficial for dishes that require low-and-slow cooking methods

Its heavy construction helps maintain a consistent temperature, which is particularly beneficial for dishes that require low-and-slow cooking methods Its heavy construction helps maintain a consistent temperature, which is particularly beneficial for dishes that require low-and-slow cooking methods cookpot enamelled cast iron cookware.

cookpot enamelled cast iron cookware.A non-stick pan is what you use if you're cooking foods that tend to stick.