best submersible slurry pump factories

Latest articles

Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

best submersible slurry pump factories...

best submersible slurry pump factories 【best submersible slurry pump factories】

Read More- Smaller, more efficient tank - Because the motor is cooled by the surrounding liquid, the submersible slurry pump can be started up to 30 times per hour, resulting in a smaller, more efficient tank.

best submersible slurry pump factories...

best submersible slurry pump factories 【best submersible slurry pump factories】

Read MoreSlurry Pump Impeller

best submersible slurry pump factories...

best submersible slurry pump factories 【best submersible slurry pump factories】

Read MoreWhy would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

best submersible slurry pump factories...

best submersible slurry pump factories 【best submersible slurry pump factories】

Read MoreStep 1

best submersible slurry pump factories...

best submersible slurry pump factories 【best submersible slurry pump factories】

Read More3. Both pumps and motors are designed separately.

best submersible slurry pump factories...

best submersible slurry pump factories 【best submersible slurry pump factories】

Read More2. All have vertical pumps and horizontal pumps and can convey slurry.

best submersible slurry pump factories...

best submersible slurry pump factories 【best submersible slurry pump factories】

Read MoreSlurry Pump

best submersible slurry pump factories...

best submersible slurry pump factories 【best submersible slurry pump factories】

Read MoreMagnetite mixing

best submersible slurry pump factories...

best submersible slurry pump factories 【best submersible slurry pump factories】

Read MoreIf you want to get more information about the slurry pumps for sale, welcome to target=_blank title=Contact Us>contact us.

best submersible slurry pump factories...

best submersible slurry pump factories 【best submersible slurry pump factories】

Read More

Popular articles

- Low slurry flow rates

- TL FGD Pump

- Corrosiveness of the slurry

- Repairable - target=_blank title=Rubber Lined Slurry Pumps>Rubber lined slurry pumps can be repaired by simply replacing the bushing.

- The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

- Slurry Pump

Latest articles

-

Determine the operating parameters of the pump.

-

AIER will always strive to be your common sense slurry pump and parts supplier in a complex world!

-

Slurry pumps can be used for.

-

Depending on the abrasive nature of the slurry, it is important to select the ideal seal. Slurry pump seals should have a hardened surface made of silicon carbide or tungsten carbide. Vortex pumps use patented seal technology that utilizes a double mechanical seal setup and a separate seal flushing system. This allows the sealing surface to be kept cool at all times without causing the slurry to overheat the seal and crack the surface.

-

Slurry Pump

-

Step 1

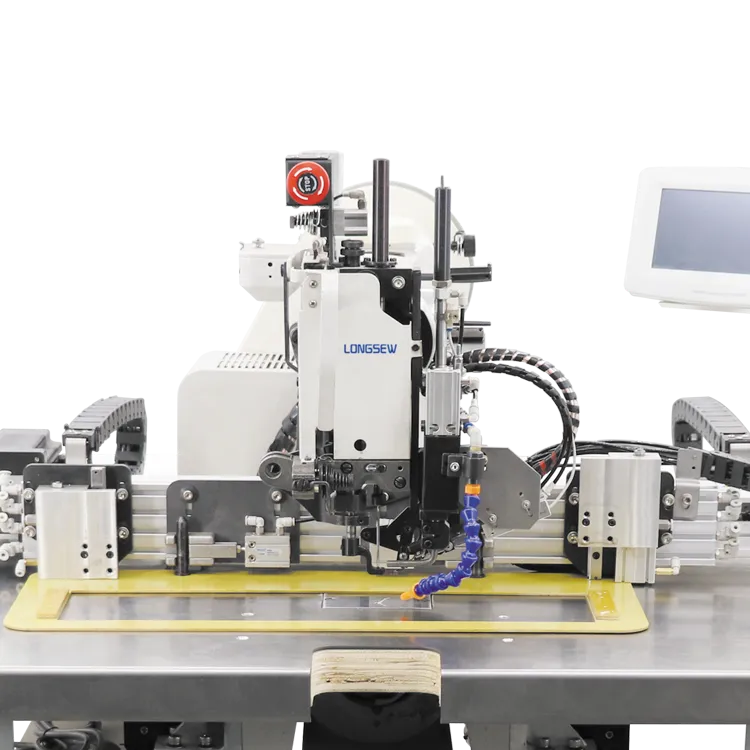

3. Juki TL-2010Q This professional-grade machine is perfect for quilting and leatherwork. It has a powerful motor, a large throat space, and is designed for high-performance sewing.

Conclusion

To ensure the overlock machine rate remains competitive, manufacturers can take several steps

1. Choose the Right Needle Size Long upholstery needles come in various sizes, and selecting the appropriate size for your project is crucial. Thicker fabrics and multiple layers may require a larger needle size to facilitate a smooth sewing experience.

Understanding Fully Automatic Sewing Machines

In conclusion, a long arm walking foot sewing machine is a valuable addition to any sewing enthusiast’s toolkit. With its versatility, ease of use, and capacity to handle larger projects, this machine can elevate your crafting capabilities. If you are considering investing in one, do your research to find the model that best fits your needs and budget. By doing so, you'll ensure that your sewing experience becomes more enjoyable and fulfilling, allowing your creativity to flourish. Whether you are quilting, sewing garments, or tackling home decor projects, a long arm walking foot sewing machine is sure to become your new best friend in the world of fabric and thread.

Key Features of Heavy-Duty Quilting Sewing Machines

- Needle Compatibility Ensure that the machine can accommodate various needle sizes that are suitable for leather work. Larger needles are typically required for thicker leather.

One of the key features of heavy duty sewing machines is their ability to sew through multiple layers of thick fabric without compromising the quality of the stitches. They also come with a variety of specialized presser feet and needles to accommodate different types of heavy fabrics. Additionally, heavy duty sewing machines often have a larger workspace to accommodate bigger projects and more room for maneuvering bulky materials.

One of the key advantages of the modern bobbin shuttle hook is its ability to handle a wide range of fabrics, from delicate silks to heavy-duty denim. This versatility is crucial for textile manufacturers who need to adapt to different projects quickly. The precision engineering of the hook ensures that stitches remain consistent, even under varying tensions and fabric types. Additionally, advancements in materials have led to stronger and more durable hooks, thereby extending the lifespan of sewing machines and reducing maintenance costs.

Moreover, the lockstitch method produces a neat, flat seam that is visually appealing, making it a preferred choice for many styles of clothing. Unlike other stitch types, such as chain stitch or overlock, the lockstitch leaves little to no bulk on the seam, allowing for smooth finishes that are essential for both aesthetics and comfort.

With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged

With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged With a sewing machine, the speed and precision are increased, but the essence of the chain remains unchanged