high quality slurry pump body casing

Latest articles

Carbon transfer

high quality slurry pump body casing...

high quality slurry pump body casing 【high quality slurry pump body casing】

Read MoreThere is a science behind the design of a >slurry pump, based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

high quality slurry pump body casing...

high quality slurry pump body casing 【high quality slurry pump body casing】

Read MoreChoosing the right pump for your slurry is critical to getting the most out of it. Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear caused by abrasive slurries. Compared to low-viscosity liquid pumps, target=_blank title=Slurry Pump>slurry pumps are typically larger and often require more horsepower to operate because they are less efficient. Bearings and shafts must also be more robust and durable.

high quality slurry pump body casing...

high quality slurry pump body casing 【high quality slurry pump body casing】

Read Moremethod and level of design reach international advanced level. The company has the first-class pump performance

high quality slurry pump body casing...

high quality slurry pump body casing 【high quality slurry pump body casing】

Read MoreWL Series Light-duty pumps are cantilevered, horizontal centrifugal slurry pumps. They are suitable for delivering low density slurries for metallurgical, mining, coal and building material departments. The shaft seal adopts both gland seal and centrifugal seal.

high quality slurry pump body casing...

high quality slurry pump body casing 【high quality slurry pump body casing】

Read MoreWhat is a dredging pump?

high quality slurry pump body casing...

high quality slurry pump body casing 【high quality slurry pump body casing】

Read MoreTo reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

high quality slurry pump body casing...

high quality slurry pump body casing 【high quality slurry pump body casing】

Read MoreMake sure you follow the basic rules of pump piping.

high quality slurry pump body casing...

high quality slurry pump body casing 【high quality slurry pump body casing】

Read MoreConsideration should be given to installing mixers on guide rods in the catch basin/tank to keep solids in suspension and avoid settling in the catch basin/tank. When investing in a slurry pump, you want to pump slurry that includes solids, not just dirty water. Therefore, it is important to make sure that the pump is doing this; by using an agitator, the pump is fed with solids and pumping the slurry.

high quality slurry pump body casing...

high quality slurry pump body casing 【high quality slurry pump body casing】

Read MoreSlurry Pump Impeller Type

high quality slurry pump body casing...

high quality slurry pump body casing 【high quality slurry pump body casing】

Read More

Popular articles

- I hope this short blog has helped to clear up some of the confusion about the seal flush programme. Please always refer to the pump manual for specific details. If there are still questions, welcome to >contact us today.

- Rubber is lighter and softer than other wear lining materials. This aids installation because it is easier to lift and install quickly and efficiently. Positive results for the health and safety of workers in the field.

- Slurry Pump

- In a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

- As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

- A slurry pump is a mechanical device used for the pressure-driven transfer of a fluid mixture (aka slurry). The fluid mixture consists largely of water as a liquid and solids as minerals, sand, gravel, human excrement, drilling mud or mostly crushed material.

Latest articles

-

What are the materials used to construct the pump?

-

2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

-

>Slurry Pump

-

Advantages of rubber

-

Slurry Pump Impeller

-

Step 4

Links

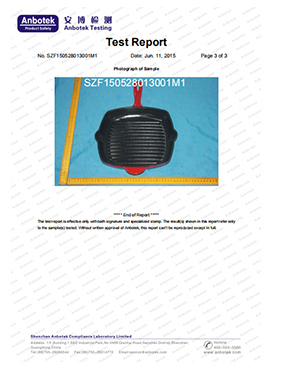

Kitchen Cookware Multifunction Rectangular Frying Pan Cast lron Wok

- Another benefit of pre-seasoned cast iron skillets is their ability to go from stovetop to oven. This makes them perfect for one-pan meals, where you can sear meat on the stovetop and then finish it off in the oven. The high heat retention of cast iron also means that dishes cooked in these skillets come out with a delicious, crispy exterior and a tender, juicy interior.

- Caring for a flat griddle pan cast iron is another aspect that sets it apart from other types of cookware. Proper seasoning—applying a thin layer of oil and heating the pan—creates a natural, non-stick surface that improves with age. The more you use your cast iron, the better the seasoning becomes, leading to an almost ritualistic care process that many find rewarding.

- 1. Le Creuset Signature Round Dutch Oven Renowned for its quality and versatility, this French classic comes in a variety of colors and is perfect for slow-cooking stews and braises.

- Non-stick skillets, usually featuring a Teflon coating, provide effortless food release and easy cleaning. On sale, they offer an affordable way to introduce convenience into daily cooking routines, particularly for those who prefer healthier cooking methods with less oil.

- One of the things that sets the Big Bacon Press apart from other kitchen gadgets is its versatility

Q: What is the best type of frying pan for cooking delicate dishes?

A: The best type of frying pan for cooking delicate dishes is one that is made from materials that provide non-stick properties and fast heating capabilities, such as ceramic and titanium frying pans.

Advantages Of Cast Iron Griddle Skillet

enameled cast iron cookware safe

Seasoning creates a layer of polymerized oil on the surface of the cast iron, which helps to prevent food from sticking and protects the metal from rusting Seasoning creates a layer of polymerized oil on the surface of the cast iron, which helps to prevent food from sticking and protects the metal from rusting

Seasoning creates a layer of polymerized oil on the surface of the cast iron, which helps to prevent food from sticking and protects the metal from rusting Seasoning creates a layer of polymerized oil on the surface of the cast iron, which helps to prevent food from sticking and protects the metal from rusting griddle plate cast iron. To season your griddle plate, simply rub a thin layer of oil all over the surface and heat it in the oven or on the stovetop until it starts to smoke. Repeat this process a few times to build up a durable seasoning layer.

griddle plate cast iron. To season your griddle plate, simply rub a thin layer of oil all over the surface and heat it in the oven or on the stovetop until it starts to smoke. Repeat this process a few times to build up a durable seasoning layer.Outdoor Cooking: The potjie pot is well-suited for outdoor cooking, making it a popular choice for camping, barbecues, and outdoor gatherings. Its robust construction and ability to withstand open flames and coals make it an ideal companion for outdoor culinary adventures.

*When in doubt, just remember this: you can often perform the same cooking tasks in either a skillet or a sauté pan, but keep in mind that the angle of the sidewalls of each pan differ, which means that one might be better suited than the other for certain cooking tasks.*

They're obviously more expensive than other non-stick pans, but they last longer. So if you're looking for a frying pan that will last you a long time, get a hard-anodized one.

cast iron soup pot. They can be passed down through generations, accumulating stories and memories along the way. A well-seasoned cast iron pot acquires a natural non-stick surface that improves with age, becoming increasingly versatile with use.

cast iron soup pot. They can be passed down through generations, accumulating stories and memories along the way. A well-seasoned cast iron pot acquires a natural non-stick surface that improves with age, becoming increasingly versatile with use.