polyurethane slurry pump factories

Latest articles

Choosing Dry Slurry Pumps Versus Submersible Slurry Pumps

polyurethane slurry pump factories...

polyurethane slurry pump factories 【polyurethane slurry pump factories】

Read MoreRubber is lighter and softer than other wear lining materials. This aids installation because it is easier to lift and install quickly and efficiently. Positive results for the health and safety of workers in the field.

polyurethane slurry pump factories...

polyurethane slurry pump factories 【polyurethane slurry pump factories】

Read MoreVertical Slurry Pumps Pump Sewage More Efficiently

polyurethane slurry pump factories...

polyurethane slurry pump factories 【polyurethane slurry pump factories】

Read MoreCustomised solutions

polyurethane slurry pump factories...

polyurethane slurry pump factories 【polyurethane slurry pump factories】

Read Morereduce the discharge pressure of the pump to the lowest possible point, and.

polyurethane slurry pump factories...

polyurethane slurry pump factories 【polyurethane slurry pump factories】

Read MoreSeries of TL >FGD pump is a single stage single suction horizontal centrifugal pump. It is mainly used as the circulation pump for absorbent tower in FGD applications. It has such features: wide range flowing capacity, high efficiency, high saving power. This series of pump is matched by tight structure X bracket which can save much space. Meanwhile our company develops many kinds of material targeted on the pumps for FGD.

polyurethane slurry pump factories...

polyurethane slurry pump factories 【polyurethane slurry pump factories】

Read MoreProcess speed doesn’t have anything to do with choosing slurry pump impeller, but it does have an effect on the life of slurry pump impeller. It is important to find the sweet spot that allows the slurry pump to run as slow as possible, but fast enough to keep solids from settling and clogging. If pumping too fast, the slurry can quickly erode the impeller due to its abrasive nature. This is why it is important to select a larger impeller if possible.

polyurethane slurry pump factories...

polyurethane slurry pump factories 【polyurethane slurry pump factories】

Read MoreIf pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

polyurethane slurry pump factories...

polyurethane slurry pump factories 【polyurethane slurry pump factories】

Read MoreWill solids size pass through the pump?

polyurethane slurry pump factories...

polyurethane slurry pump factories 【polyurethane slurry pump factories】

Read MoreSeries of TL >FGD pump is a single stage single suction horizontal centrifugal pump. It is mainly used as the circulation pump for absorbent tower in FGD applications. It has such features: wide range flowing capacity, high efficiency, high saving power. This series of pump is matched by tight structure X bracket which can save much space. Meanwhile our company develops many kinds of material targeted on the pumps for FGD.

polyurethane slurry pump factories...

polyurethane slurry pump factories 【polyurethane slurry pump factories】

Read More

Popular articles

- Slurry Pump

- If you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

- Keep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

- Process speed doesn’t have anything to do with choosing slurry pump impeller, but it does have an effect on the life of slurry pump impeller. It is important to find the sweet spot that allows the slurry pump to run as slow as possible, but fast enough to keep solids from settling and clogging. If pumping too fast, the slurry can quickly erode the impeller due to its abrasive nature. This is why it is important to select a larger impeller if possible.

- What is a slurry pump?

- There are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

Latest articles

-

The Company Adopts Advanced Computer Aided Engineering Software

-

factors-to-consider-when-choosing-a-slurry-pump

-

Metal and/or rubber pump bushings are used to combat the erosion of solid particles found in the slurry. Metal slurry pump housings are usually made of carbide to resist erosion caused by increased pressure and circulation. Sometimes wear-resistant steel is used on the pump casing so that the pump can be welded if repairs are needed.

-

- transport solids hydraulically

-

>Slurry Pump

-

Slurry Pump

Links

- The antibacterial properties of these towels come from the materials they are made of. Many antibacterial towels are infused with silver, which has natural antimicrobial properties. Silver has been used for centuries as a way to prevent the growth of bacteria, making it an ideal material for towels that are used in places where bacteria are likely to thrive, such as in the kitchen and bathroom.

Bed Valance

Oversized sheets, while allowing for extra room, can also create excess fabric that can bunch up and cause displacement Oversized sheets, while allowing for extra room, can also create excess fabric that can bunch up and cause displacement

Oversized sheets, while allowing for extra room, can also create excess fabric that can bunch up and cause displacement Oversized sheets, while allowing for extra room, can also create excess fabric that can bunch up and cause displacement sheets that don t slip off. Therefore, it's essential to measure your mattress accurately and choose the appropriate size.

sheets that don t slip off. Therefore, it's essential to measure your mattress accurately and choose the appropriate size. From casual weekend lounging to hotel stays, spa visits, or even as a wedding attire for the groom and his groomsmen, the white waffle robe has proven its versatility time and again From casual weekend lounging to hotel stays, spa visits, or even as a wedding attire for the groom and his groomsmen, the white waffle robe has proven its versatility time and again

From casual weekend lounging to hotel stays, spa visits, or even as a wedding attire for the groom and his groomsmen, the white waffle robe has proven its versatility time and again From casual weekend lounging to hotel stays, spa visits, or even as a wedding attire for the groom and his groomsmen, the white waffle robe has proven its versatility time and again white waffle robe mens.

white waffle robe mens.

What is a Duvet Cover, and what is it used for?

Commonly used in North America, but uncommon in Europe, a top sheet (also known as a flat sheet), is the sheet that separates you from your comforter, blanket, or quilt. In Europe (and very slowly catching on in the United States), the duvet cover takes the place of the top sheet.

microfiber pillow is good or bad. One potential downside is that they can retain heat more than other pillow materials. This can be uncomfortable for some people, especially those who tend to sleep hot. To combat this, some microfiber pillows come with cooling properties to help regulate temperature and keep the sleeper comfortable throughout the night.

microfiber pillow is good or bad. One potential downside is that they can retain heat more than other pillow materials. This can be uncomfortable for some people, especially those who tend to sleep hot. To combat this, some microfiber pillows come with cooling properties to help regulate temperature and keep the sleeper comfortable throughout the night. large cotton towels. Their thick, fluffy texture allows them to hold more water than smaller towels, meaning you can dry off quickly and efficiently. Whether you're stepping out of the shower or washing your hands, these towels will provide you with the absorbency you need to stay dry and comfortable.

large cotton towels. Their thick, fluffy texture allows them to hold more water than smaller towels, meaning you can dry off quickly and efficiently. Whether you're stepping out of the shower or washing your hands, these towels will provide you with the absorbency you need to stay dry and comfortable.Cotton is a staple fabric spun from the fibers of cotton plants. People around the world have been cultivating it for thousands of years. One of the earliest bits of cotton is at least 7,000 years old and was found in Mexico. In Egypt and Pakistan, people were weaving cotton thread into clothing in 3,000 BC. And in the 18th century, the British first found a way to spin cotton into textile with machinery.

waffle terry bathrobe. The strong stitching and reinforced seams ensure that it can withstand everyday wear and tear, making it a smart investment for anyone looking for a long-lasting loungewear option.

It is also easier to clean and maintain compared to other fabrics It is also easier to clean and maintain compared to other fabrics

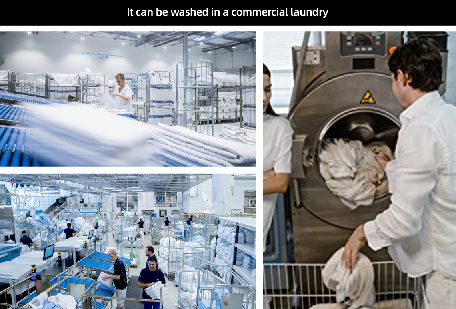

It is also easier to clean and maintain compared to other fabrics It is also easier to clean and maintain compared to other fabrics hospital bed cotton sheets. Hospital-grade cotton sheets can withstand repeated washings at high temperatures, effectively eliminating bacteria and germs, ensuring a hygienic environment for patients.

hospital bed cotton sheets. Hospital-grade cotton sheets can withstand repeated washings at high temperatures, effectively eliminating bacteria and germs, ensuring a hygienic environment for patients.

cotton polyester blend sheets reviews. They resist wrinkles more effectively than cotton and dry faster, saving time and effort. No need to iron, says a happy customer, they come out of the dryer looking fresh and ready to use.

cotton polyester blend sheets reviews. They resist wrinkles more effectively than cotton and dry faster, saving time and effort. No need to iron, says a happy customer, they come out of the dryer looking fresh and ready to use.

Cotton and cotton blends dominate the market, the most common blend being cotton/polyester. Cotton provides absorbency and a soft hand, while polyester adds durability and wrinkle resistance.[2] Other common fibers used in the manufacturing of bed sheets include linen, silk, Modal and bamboo rayon, lyocell, Microtex or Microfiber, and polypropylene. Polypropylene (olefin) is a hypoallergenic spun-bound material produced at a low cost and typically used in emergency shelters or hospitals as disposable sheeting.