wet pit mounted vertical sump pump factory

Latest articles

Selecting And Operating A Slurry Pump

wet pit mounted vertical sump pump factory...

wet pit mounted vertical sump pump factory 【wet pit mounted vertical sump pump factory】

Read MoreFewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - usually 2-5 vanes.

wet pit mounted vertical sump pump factory...

wet pit mounted vertical sump pump factory 【wet pit mounted vertical sump pump factory】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

wet pit mounted vertical sump pump factory...

wet pit mounted vertical sump pump factory 【wet pit mounted vertical sump pump factory】

Read MoreFor more information about this new and improved pump, please contact us.

wet pit mounted vertical sump pump factory...

wet pit mounted vertical sump pump factory 【wet pit mounted vertical sump pump factory】

Read MorePumping slurry can present some challenges and problems, but with proper engineering and equipment selection, you can experience years of trouble-free operation. It's important to work with a qualified engineer when selecting a slurry pump, because slurry can wreak havoc on a pump if not selected properly.

wet pit mounted vertical sump pump factory...

wet pit mounted vertical sump pump factory 【wet pit mounted vertical sump pump factory】

Read MoreIn a subsea installation, the slurry pump runs directly in the slurry and does not require a support structure, which means it is flexible and easy to install. If possible, the catch basin should be equipped with sloping walls to allow sediment to slide down into the area directly below the pump inlet. Agitators should be used when the liquid contains large amounts of solids and has a high particle density. Freestanding or side-mounted (submersible) mixers are an excellent choice for resuspended solids, especially if the catch basin is large or does not have sloping walls.

wet pit mounted vertical sump pump factory...

wet pit mounted vertical sump pump factory 【wet pit mounted vertical sump pump factory】

Read MoreChoosing the right pump for your slurry is critical to getting the most out of it. Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear caused by abrasive slurries. Compared to low-viscosity liquid pumps, target=_blank title=Slurry Pump>slurry pumps are typically larger and often require more horsepower to operate because they are less efficient. Bearings and shafts must also be more robust and durable.

wet pit mounted vertical sump pump factory...

wet pit mounted vertical sump pump factory 【wet pit mounted vertical sump pump factory】

Read MoreSlurry Pump

wet pit mounted vertical sump pump factory...

wet pit mounted vertical sump pump factory 【wet pit mounted vertical sump pump factory】

Read MoreIdeal for slurry pumps - Only rubber lined pumps combine strength and corrosion resistance to create a quality slurry pump.

wet pit mounted vertical sump pump factory...

wet pit mounted vertical sump pump factory 【wet pit mounted vertical sump pump factory】

Read MoreDetermine the size of the pump

wet pit mounted vertical sump pump factory...

wet pit mounted vertical sump pump factory 【wet pit mounted vertical sump pump factory】

Read More

Popular articles

- A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right , pump, .xa0, In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

- WA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

- It is important that the pump you choose has components that will not wear out from abrasive slurries.

- Slurry Pump

- Pump selection for FGD

- WA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

Latest articles

-

There are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

-

Aier is pumping experts and offer some useful tips to maintain your >slurry pump.

-

Is the discharge configuration suitable for abrasive slurries?

-

method and level of design reach international advanced level. The company has the first-class pump performance

-

- Low noise level - Operating underwater results in low noise or even silent operation.

-

- Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

Links

- In conclusion, enamel ware cookware is more than just a functional tool; it's a piece of culinary heritage. It combines practicality, beauty, and durability, making it a worthwhile investment for those who appreciate both the art and science of cooking. So, whether you're a seasoned chef or a beginner, consider adding a touch of enamel ware to your kitchen arsenal. It's a testament to the fact that sometimes, the old ways truly are the best.

Cast iron cookware has been a staple in the kitchen for centuries, and its enduring popularity is a testament to its durability and versatility. Whether you are an experienced cook or a novice cook, investing in cast iron cookware is a decision that can enhance your cooking experience. When considering purchasing cast iron cookware, it's important to understand the different types available and their prices to make an informed decision.

It's also perfect for making international favorites like crepes, dosas, or even Korean BBQ-style meals It's also perfect for making international favorites like crepes, dosas, or even Korean BBQ-style meals

It's also perfect for making international favorites like crepes, dosas, or even Korean BBQ-style meals It's also perfect for making international favorites like crepes, dosas, or even Korean BBQ-style meals two sided griddle.

two sided griddle.Timeless Elegance of Enamel Cookware:

Look for a pan with a long handle that stays cool even when the pan is hot, making it easier to move the pan around on the grill Look for a pan with a long handle that stays cool even when the pan is hot, making it easier to move the pan around on the grill

Look for a pan with a long handle that stays cool even when the pan is hot, making it easier to move the pan around on the grill Look for a pan with a long handle that stays cool even when the pan is hot, making it easier to move the pan around on the grill buy cast iron grill pan.

buy cast iron grill pan.Types of Non-Stick Coating

It can handle high temperatures, making it perfect for tasks like roasting, baking, or even making a mouth-watering apple crisp It can handle high temperatures, making it perfect for tasks like roasting, baking, or even making a mouth-watering apple crisp

It can handle high temperatures, making it perfect for tasks like roasting, baking, or even making a mouth-watering apple crisp It can handle high temperatures, making it perfect for tasks like roasting, baking, or even making a mouth-watering apple crisp high quality cast iron skillet.

high quality cast iron skillet.

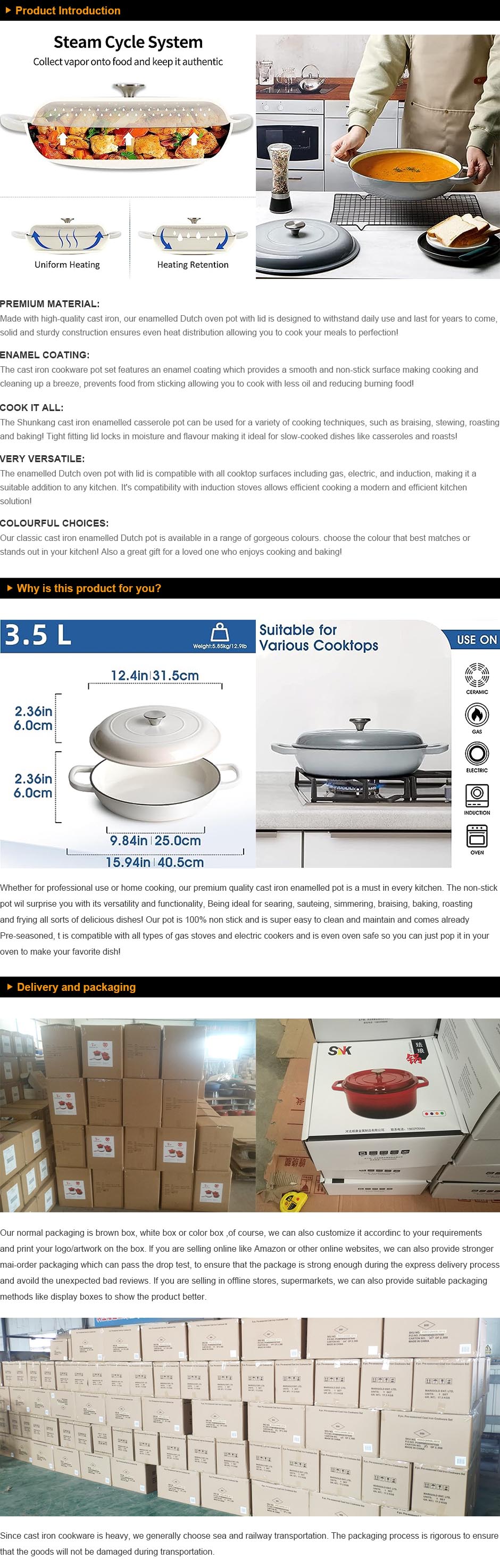

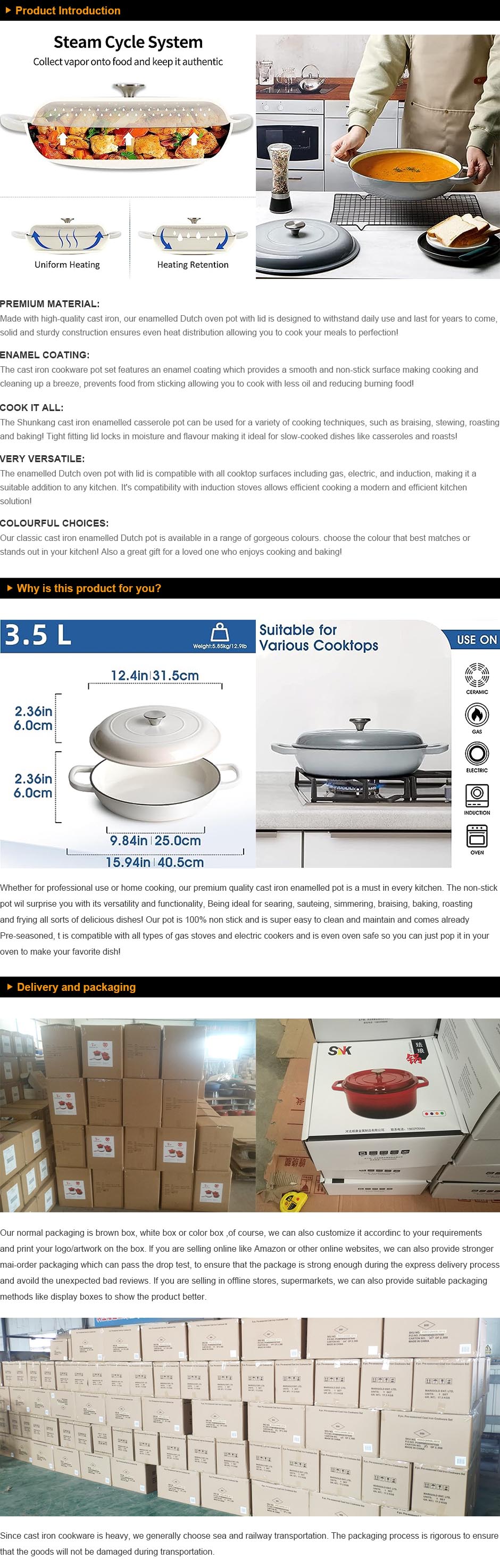

Dutch Oven Use

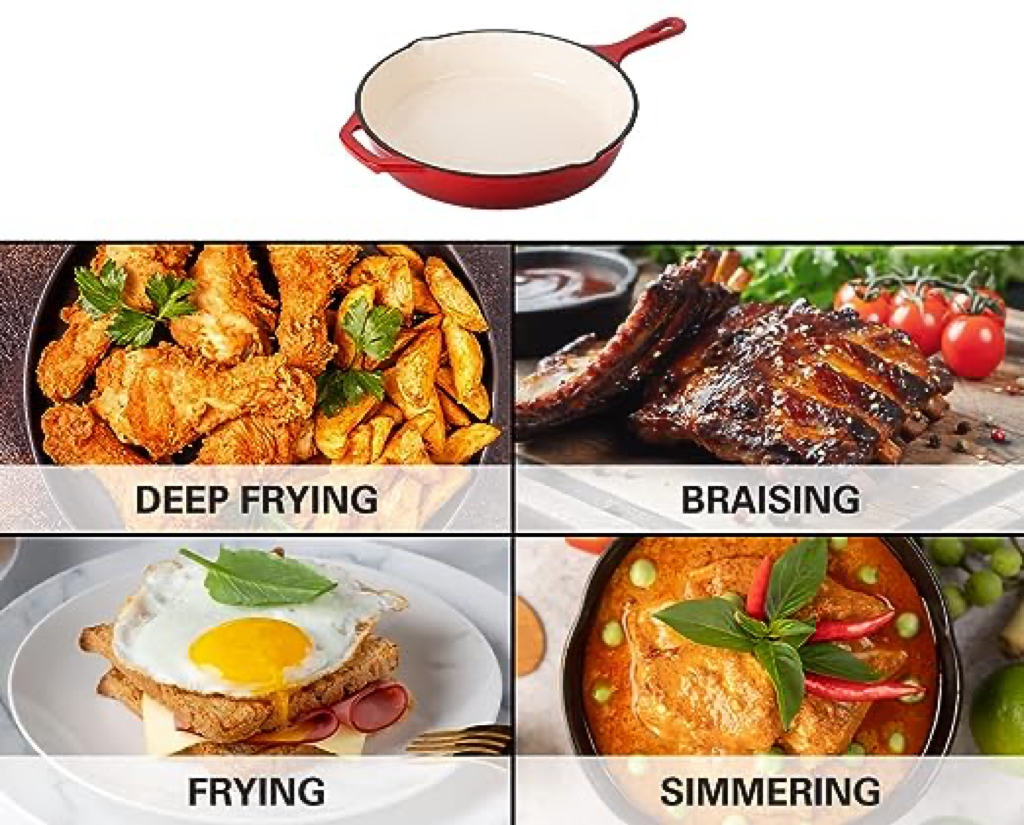

Frying pans are usually made from various materials, including cast iron, stainless steel, aluminium, and copper. Each material has unique properties that make it suitable for specific types of cooking.

Likewise, cast iron shrimp grill pans are great for cooking delicate seafood. Cast iron shrimp grill pan's high heat retention ensures the shrimp cooks evenly and quickly, caramelizing the outside while keeping the inside tender and juicy.

Frying pans have flat sides that distribute heat evenly. The low sides also act as a barrier to prevent liquid from spilling out.