china slurry pump for vapor blasting factories

Latest articles

Rubber lined pumps offer many advantages

china slurry pump for vapor blasting factories...

china slurry pump for vapor blasting factories 【china slurry pump for vapor blasting factories】

Read MoreFine-grained sand can be extremely abrasive and typically wears slurry pumps quickly. Characteristics of coarse aggregates that can affect pump performance are size, shape and surface texture, as well as gradual changes in particle size, while fine materials can create excessive friction in the pipe.

china slurry pump for vapor blasting factories...

china slurry pump for vapor blasting factories 【china slurry pump for vapor blasting factories】

Read MoreThe mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete.

china slurry pump for vapor blasting factories...

china slurry pump for vapor blasting factories 【china slurry pump for vapor blasting factories】

Read MoreIf centrifugal, are the impellers of the right design and material?

china slurry pump for vapor blasting factories...

china slurry pump for vapor blasting factories 【china slurry pump for vapor blasting factories】

Read MoreVertical Slurry Pump

china slurry pump for vapor blasting factories...

china slurry pump for vapor blasting factories 【china slurry pump for vapor blasting factories】

Read MoreAier is pumping experts and offer some useful tips to maintain your >slurry pump.

china slurry pump for vapor blasting factories...

china slurry pump for vapor blasting factories 【china slurry pump for vapor blasting factories】

Read MoreAier Machinery has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

china slurry pump for vapor blasting factories...

china slurry pump for vapor blasting factories 【china slurry pump for vapor blasting factories】

Read MoreFine-grained sand can be extremely abrasive and typically wears slurry pumps quickly. Characteristics of coarse aggregates that can affect pump performance are size, shape and surface texture, as well as gradual changes in particle size, while fine materials can create excessive friction in the pipe.

china slurry pump for vapor blasting factories...

china slurry pump for vapor blasting factories 【china slurry pump for vapor blasting factories】

Read More>Dredge pumps are a special category of pumps used in the dredging process. Dredging is the process of transporting submerged sediments (usually sand, gravel or rock) from one area to another. Dredging takes place in the shallow waters of lakes, rivers or seas for land reclamation, dredging, flood control, new harbours or expansion of existing harbours. The various industries that use dredge pumps are therefore the construction industry, mining, the coal industry and the oil and gas industry.

china slurry pump for vapor blasting factories...

china slurry pump for vapor blasting factories 【china slurry pump for vapor blasting factories】

Read MoreLess downtime

china slurry pump for vapor blasting factories...

china slurry pump for vapor blasting factories 【china slurry pump for vapor blasting factories】

Read More

Popular articles

- Typically, slurries are.

- The Mud pumps need to be equipped with auxiliary equipment, but slurry pumps not. They often need to use with high-pressure water pump when mud pump working. The high-pressure pump sent the water that larger than the mud pump pressure to the leakproof packing. Then protect the packing. Otherwise, it is easy to make the seal part wear. But the wear-resistant slurry pumps can complete the transportation work independently, which not need to equip other auxiliary equipment.

- Any type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

- Light-duty Slurry Pump

- - Pumping media where abrasive particles are present

- Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel, Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

Latest articles

-

Packing the box seal

-

We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

-

If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

-

Make sure you follow the basic rules of pump piping.

-

Selecting a dredge pump

-

What is a dredging pump?

Links

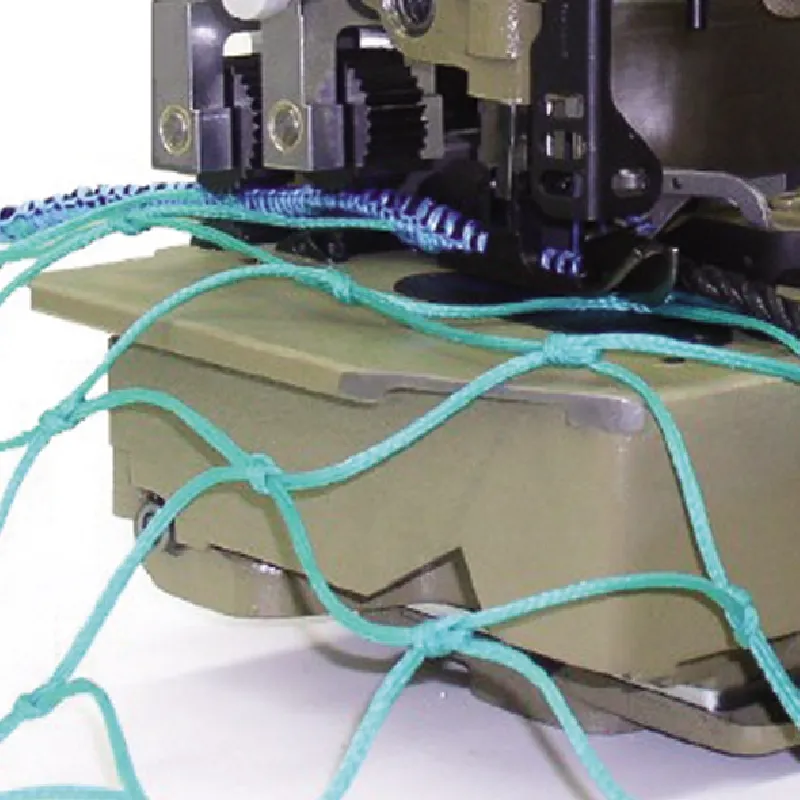

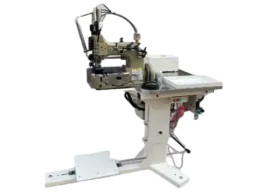

The journey of the walking needle sewing machine began in the early 20th century as the demand for more efficient sewing techniques grew in response to the booming textile industry. Before its invention, conventional sewing machines relied on fixed needles and feed mechanisms, which often resulted in uneven stitches and difficulty handling multiple layers of fabric. The introduction of the walking foot mechanism revolutionized the sewing process, allowing the needle and the fabric to move simultaneously. This not only improved the precision of stitching but also enhanced the machine’s ability to sew challenging materials, such as leather and heavy fabrics.

The lockstitch sewing machine is an essential piece of equipment in the textile industry, renowned for its efficiency and versatility. Its operation is fundamental to modern garment manufacturing, providing a durable and reliable stitch that is crucial for constructing clothing and other fabric-based products.

However, the double needle price reflects the complexities inherent in implementing this technique. The machinery required for double needle stitching is more advanced and costly than standard single needle machines. This initial investment can be a deterrent for smaller manufacturers or those operating on tight budgets. Moreover, the operation of double needle machines often requires skilled labor, further increasing production costs. Manufacturers must strike a balance between investing in quality production techniques and maintaining competitive pricing.

double needle price

The Benefits of Hand Stitching

leather hand stitcher

What are Heavy Duty Sewing Needles?

The handheld leather stitcher is more than just a tool; it is an essential companion for anyone serious about leatherworking. By enhancing efficiency, improving control, and offering versatility, this tool allows crafters to bring their creative visions to life while ensuring the durability of their projects. Whether you're crafting for personal use or starting a small business, investing in a high-quality handheld leather stitcher can be one of the best decisions you make on your leatherworking journey. With practice and dedication, you will discover the endless possibilities that this remarkable tool can offer.

What Are Chrome Sewing Machine Needles?

One of the primary advantages of manual machines is their ability to create consistent and strong stitches. The manual feeding process allows for a greater sense of rhythm and timing, which can lead to a more uniform appearance. Moreover, since there is no reliance on electricity, these machines can be used in any setting, making them ideal for workshops, outdoor projects, or anywhere where power sources may be limited.

2. Singer Quantum Stylist 9960 Known for its robust performance, this machine offers 600 built-in stitches, including a variety of fonts and decorative options. It comes with a high-speed sewing capability and an automatic thread cutter, making it ideal for more advanced sewing tasks.

industrial long arm sewing machine for sale.

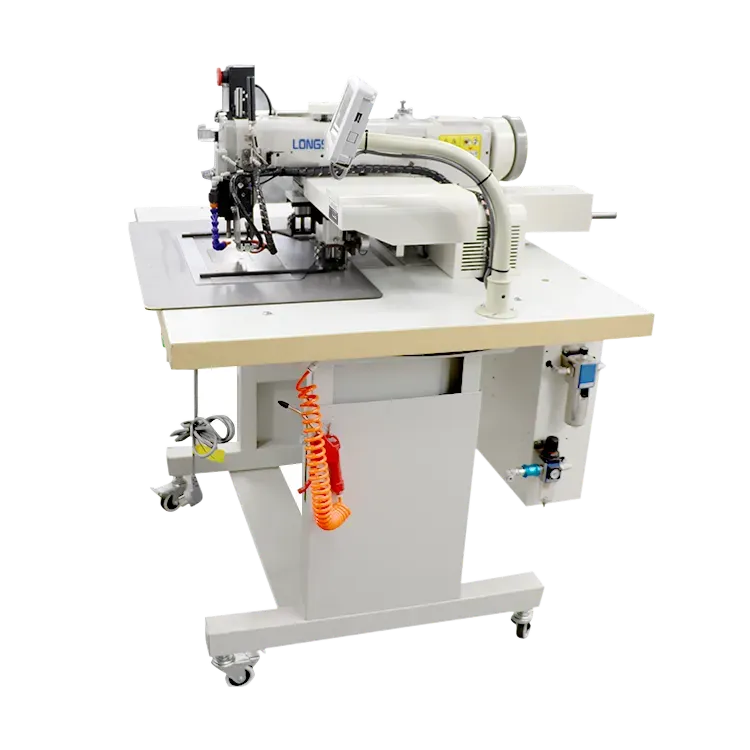

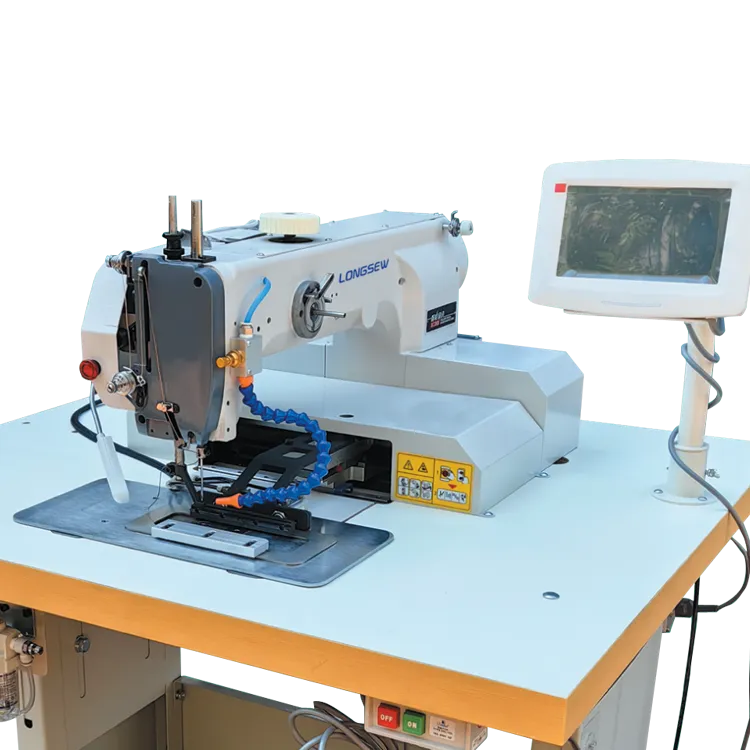

The Rise of Automatic Template Sewing Machines Revolutionizing the Textile Industry

Advantages of Long Arm Sewing

4. Variety of Stitch Options Check for machines that offer multiple stitch types, including straight, zigzag, and decorative stitches. Having these options can enhance your projects, giving you creative flexibility beyond just straight lines.

Another significant benefit is efficiency. With the ability to handle various fabric types and thicknesses, needle feed sewing machines streamline the production process, reducing the need for multiple machines and improving workflow in a manufacturing setting. This efficiency is especially crucial in today's fast-paced fashion landscape, where time-to-market is a critical factor for success.

A multi-needle quilting machine is designed with multiple needles, allowing the user to stitch various designs and patterns simultaneously. This feature significantly increases productivity, as it enables quilters to create intricate designs without the need to frequently change threads or needles. Most multi-needle machines come equipped with a wide range of built-in designs, fonts, and the capability to import custom patterns, making them versatile tools in any quilter’s arsenal.

5. User-Friendly Operation Advanced bag closing machines often incorporate user-friendly controls and interfaces, making it easier for operators to manage. Training new staff becomes less time-consuming, which is a significant advantage for companies looking to maximize productivity.

Furthermore, for those who are serious about their sewing, the speed and efficiency offered by heavy duty machines can significantly enhance productivity. More powerful motors enable faster stitching, which is essential for meeting tight deadlines or finishing multiple projects in a timely manner.

2. Professional Finish The parallel stitching produced by dual needles gives garments a polished and professional look. This is especially beneficial in sewing hems, where two lines of stitching can add a decorative touch while also strengthening the hem.

Moreover, these machines often have powerful motors that can handle the stiffness of leather, making them robust enough for heavy-duty applications. They are designed to handle various stitch types, including straight, zigzag, and decorative stitches, giving artisans the versatility they need to create intricate designs.

cylinder arm sewing machine leather

Construction and Durability

At its core, the single needle stitch involves using a single needle to make individual stitches, which can be hand-sewn or machine-sewn. This technique is particularly favored for its ability to provide fine detail and a polished finish, making it essential in high-quality garment construction, tailoring, and decorative embroidery. When executed properly, the single needle stitch results in minimal fabric distortion, ensuring that garments fit seamlessly and have a professional appearance.

Understanding the Basics

Advantages of Using Coverstitch

Although it was initially designed for industrial use, nowadays, the heavy duty sewing machine has become a popular choice for home use, too. The sewing machine adds to the whole sewing experience, therefore experienced tailors around the world choose heavy duty sewing machines over the normal ones. But what is the best heavy duty sewing machine for home use?