high quality vertical spindle slurry pump manufacturers

Latest articles

>TL FGD Pump

high quality vertical spindle slurry pump manufacturers...

high quality vertical spindle slurry pump manufacturers 【high quality vertical spindle slurry pump manufacturers】

Read More- Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

high quality vertical spindle slurry pump manufacturers...

high quality vertical spindle slurry pump manufacturers 【high quality vertical spindle slurry pump manufacturers】

Read MoreThere are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

high quality vertical spindle slurry pump manufacturers...

high quality vertical spindle slurry pump manufacturers 【high quality vertical spindle slurry pump manufacturers】

Read MoreThe winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

high quality vertical spindle slurry pump manufacturers...

high quality vertical spindle slurry pump manufacturers 【high quality vertical spindle slurry pump manufacturers】

Read MoreSlurry pumps can be used to transport mixtures of liquids and solids in many industries in a wide range of applications, such as mine drainage, dredging of sunken lagoons and pumping of drilling mud.

high quality vertical spindle slurry pump manufacturers...

high quality vertical spindle slurry pump manufacturers 【high quality vertical spindle slurry pump manufacturers】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of , dredging pumps, is also increasing.

high quality vertical spindle slurry pump manufacturers...

high quality vertical spindle slurry pump manufacturers 【high quality vertical spindle slurry pump manufacturers】

Read MoreLarger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

high quality vertical spindle slurry pump manufacturers...

high quality vertical spindle slurry pump manufacturers 【high quality vertical spindle slurry pump manufacturers】

Read MoreLess downtime

high quality vertical spindle slurry pump manufacturers...

high quality vertical spindle slurry pump manufacturers 【high quality vertical spindle slurry pump manufacturers】

Read MoreOur firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

high quality vertical spindle slurry pump manufacturers...

high quality vertical spindle slurry pump manufacturers 【high quality vertical spindle slurry pump manufacturers】

Read MoreDredge Pump

high quality vertical spindle slurry pump manufacturers...

high quality vertical spindle slurry pump manufacturers 【high quality vertical spindle slurry pump manufacturers】

Read More

Popular articles

- Aier Machinery has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

- A quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

- Submersible slurry pump pumps offer many advantages over dry and semi-dry (cantilever) mounted pumps.

- Abrasive.

- Slurry Pump

- Types of damage to slurry pumps

Latest articles

-

Using rubber as a wear lining material means

-

A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

-

The Mud pumps need to be equipped with auxiliary equipment, but slurry pumps not. They often need to use with high-pressure water pump when mud pump working. The high-pressure pump sent the water that larger than the mud pump pressure to the leakproof packing. Then protect the packing. Otherwise, it is easy to make the seal part wear. But the wear-resistant slurry pumps can complete the transportation work independently, which not need to equip other auxiliary equipment.

-

>Slurry pumps are typically larger than standard pumps, with more horsepower and stronger bearings and shafts. The most common type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids move through a standard centrifugal pump.

-

Slurry Pump

-

All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

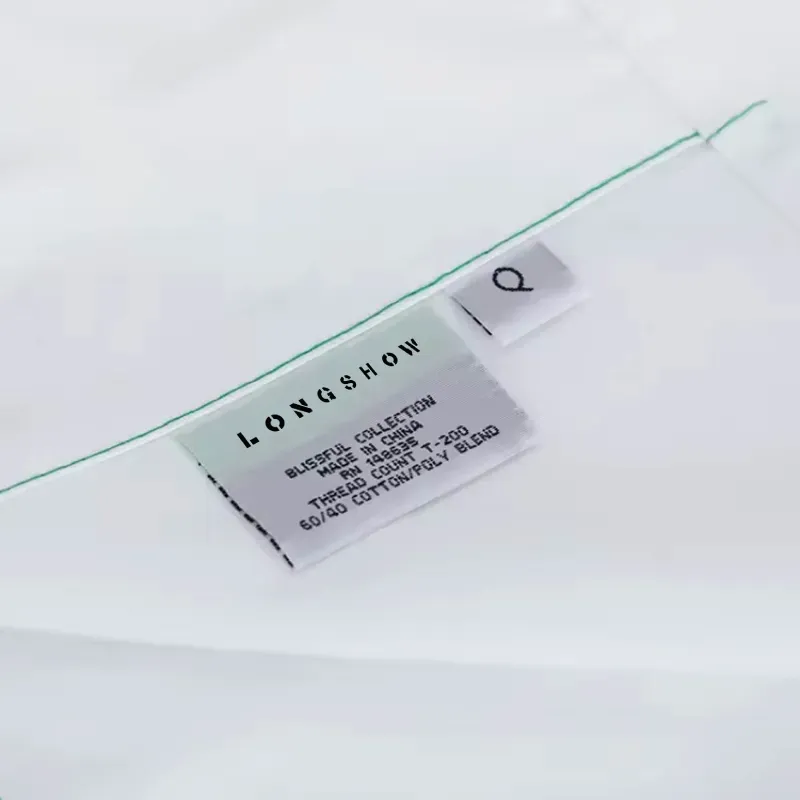

Tencel:Tencel is a similar material to bamboo viscose. However, it is made from eucalyptus instead of bamboo and uses a slightly different manufacturing process. Tencel is actually a brand name — the generic term for this material is eucalyptus lyocell.

do you need a duvet insert. By switching out the insert based on the season, you can easily adjust the warmth level of your bedding. This is particularly beneficial for individuals who experience fluctuating room temperatures or have varying warmth preferences.

do you need a duvet insert. By switching out the insert based on the season, you can easily adjust the warmth level of your bedding. This is particularly beneficial for individuals who experience fluctuating room temperatures or have varying warmth preferences.Percale:Percale is one of the most commonly used weaves for sheets. Also sometimes known as a plain weave, percale is a one yarn over, one yarn under weave. That means the warp (lengthwise threads) and weft (horizontal threads) will be equal in number.

These are simple to take care of and are resistant to creases.

In addition, the extra width provides more room for experimentation with draping, gathering, or pleating, adding depth and dimension to the final product In addition, the extra width provides more room for experimentation with draping, gathering, or pleating, adding depth and dimension to the final product

In addition, the extra width provides more room for experimentation with draping, gathering, or pleating, adding depth and dimension to the final product In addition, the extra width provides more room for experimentation with draping, gathering, or pleating, adding depth and dimension to the final product extra wide material.

extra wide material. Synthetic fillers, like polyester, offer a more affordable alternative with comparable insulation properties Synthetic fillers, like polyester, offer a more affordable alternative with comparable insulation properties

Synthetic fillers, like polyester, offer a more affordable alternative with comparable insulation properties Synthetic fillers, like polyester, offer a more affordable alternative with comparable insulation properties duvet cover and filler. Feather fillers provide a medium level of warmth and are generally more affordable than down.

duvet cover and filler. Feather fillers provide a medium level of warmth and are generally more affordable than down.

Ultimately, the choice of silk vs. flannel sheets and the specific qualities of king sheets comes down to personal preference and needs. By considering factors like bed sheet material, thread count, and fit, you can make an informed decision and choose great quality sheets that will provide comfort and satisfaction for years to come.

They represent our presentation to the world, reflecting our personality and status They represent our presentation to the world, reflecting our personality and status

They represent our presentation to the world, reflecting our personality and status They represent our presentation to the world, reflecting our personality and status wash cloth. The act of washing clothes, therefore, becomes an expression of self-care and grooming.

wash cloth. The act of washing clothes, therefore, becomes an expression of self-care and grooming.

The fabric and fibre

One of the most common applications of twill is to create denim, but it is also used in sheets and other bedding. Twill tends to have a higher thread count, which also makes it a warmer fabric.