high quality pond dredge pump suppliers

Latest articles

Settling slurries are formed from coarse particles; they are formed from unstable mixtures. It is these settling slurries with coarse particles.

high quality pond dredge pump suppliers...

high quality pond dredge pump suppliers 【high quality pond dredge pump suppliers】

Read MoreTo reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

high quality pond dredge pump suppliers...

high quality pond dredge pump suppliers 【high quality pond dredge pump suppliers】

Read MoreSlurry Pump Impeller

high quality pond dredge pump suppliers...

high quality pond dredge pump suppliers 【high quality pond dredge pump suppliers】

Read MoreStep 3

high quality pond dredge pump suppliers...

high quality pond dredge pump suppliers 【high quality pond dredge pump suppliers】

Read MorePumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.

high quality pond dredge pump suppliers...

high quality pond dredge pump suppliers 【high quality pond dredge pump suppliers】

Read MoreParticle size, shape and hardness (impact on wear and corrosion potential of pump components)

high quality pond dredge pump suppliers...

high quality pond dredge pump suppliers 【high quality pond dredge pump suppliers】

Read MoreSlurry Pump

high quality pond dredge pump suppliers...

high quality pond dredge pump suppliers 【high quality pond dredge pump suppliers】

Read MoreUnderwater installation

high quality pond dredge pump suppliers...

high quality pond dredge pump suppliers 【high quality pond dredge pump suppliers】

Read MoreRubber lined pumps offer many advantages

high quality pond dredge pump suppliers...

high quality pond dredge pump suppliers 【high quality pond dredge pump suppliers】

Read MoreThe rule of thumb for setting the water pressure is the same when using the pack box, whether flushing. Mud pump shut-off pressure plus 10% or plus 20 psi, whichever is greater. However, the flow rate is set differently.

high quality pond dredge pump suppliers...

high quality pond dredge pump suppliers 【high quality pond dredge pump suppliers】

Read More

Popular articles

- Consideration should be given to installing mixers on guide rods in the catch basin/tank to keep solids in suspension and avoid settling in the catch basin/tank. When investing in a slurry pump, you want to pump slurry that includes solids, not just dirty water. Therefore, it is important to make sure that the pump is doing this; by using an agitator, the pump is fed with solids and pumping the slurry.

- It is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

- Slurry pumps can be used to transport mixtures of liquids and solids in many industries in a wide range of applications, such as mine drainage, dredging of sunken lagoons and pumping of drilling mud.

- Dredge pumps are designed to transfer large quantities of fluids and solids.

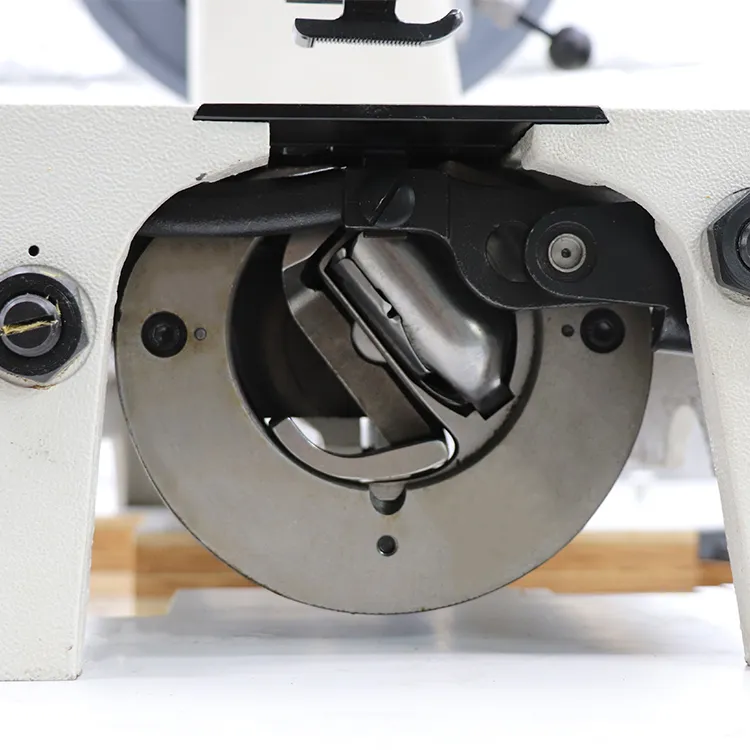

- The impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

- of a thick consistency, and.

Latest articles

-

Slurry Pump

-

What is the pump constructed of?

-

For example.

-

Slurry pump impeller, is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

-

testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

-

There are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

Another noteworthy application of the zigzag foot is its proficiency in finishing edges—an essential technique that helps prevent fraying. The smooth, continuous motion of the zigzag around the fabric perimeter helps secure the edges and provides a polished look to garments and accessories. This multifunctionality simplifies the sewing process, enabling makers to focus more on design and creativity rather than on tedious finishing techniques.

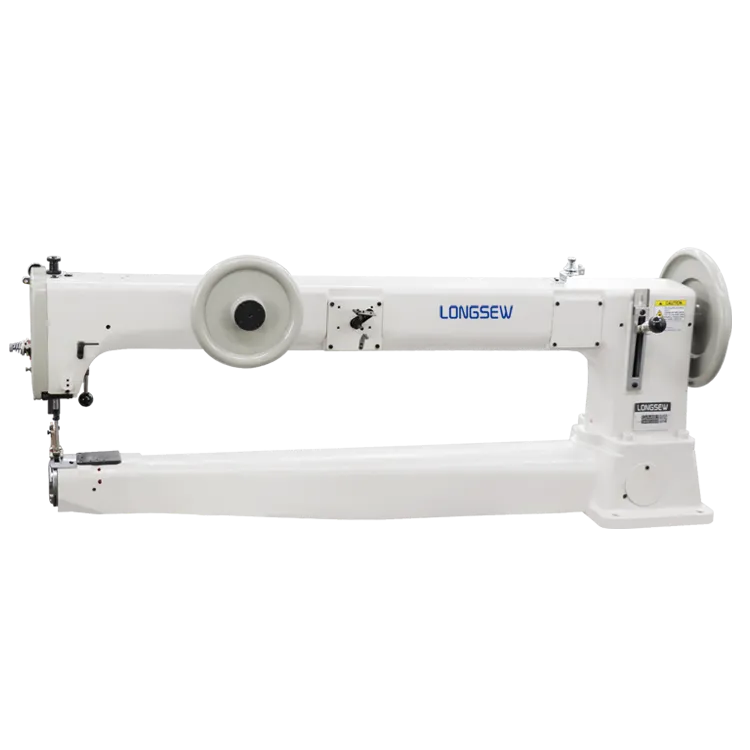

Understanding the Prices of Saddle Stitch Machines

Testimonials from Users of Heavy-Duty Sewing Machines