high quality centrifual slurry pump spare parts manufacturer

Latest articles

If you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

high quality centrifual slurry pump spare parts manufacturer...

high quality centrifual slurry pump spare parts manufacturer 【high quality centrifual slurry pump spare parts manufacturer】

Read MoreThere is a better way to pump sewage, overflows and other collected dirty water around the plant.

high quality centrifual slurry pump spare parts manufacturer...

high quality centrifual slurry pump spare parts manufacturer 【high quality centrifual slurry pump spare parts manufacturer】

Read More>Slurry Pump

high quality centrifual slurry pump spare parts manufacturer...

high quality centrifual slurry pump spare parts manufacturer 【high quality centrifual slurry pump spare parts manufacturer】

Read MoreAll products are mainly supplied to environmental protection, wastewater treatment, urban water supply and drainage, mine, metallurgy, coal, petrochemical, building material, thermal power FGD, river dredging, tailing disposal and other fields.

high quality centrifual slurry pump spare parts manufacturer...

high quality centrifual slurry pump spare parts manufacturer 【high quality centrifual slurry pump spare parts manufacturer】

Read More- Smaller, more efficient tank - Because the motor is cooled by the surrounding liquid, the submersible slurry pump can be started up to 30 times per hour, resulting in a smaller, more efficient tank.

high quality centrifual slurry pump spare parts manufacturer...

high quality centrifual slurry pump spare parts manufacturer 【high quality centrifual slurry pump spare parts manufacturer】

Read MoreKeep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

high quality centrifual slurry pump spare parts manufacturer...

high quality centrifual slurry pump spare parts manufacturer 【high quality centrifual slurry pump spare parts manufacturer】

Read MoreChoosing The Right Slurry Pump For Your Application

high quality centrifual slurry pump spare parts manufacturer...

high quality centrifual slurry pump spare parts manufacturer 【high quality centrifual slurry pump spare parts manufacturer】

Read MoreThe FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

high quality centrifual slurry pump spare parts manufacturer...

high quality centrifual slurry pump spare parts manufacturer 【high quality centrifual slurry pump spare parts manufacturer】

Read MoreUnder ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

high quality centrifual slurry pump spare parts manufacturer...

high quality centrifual slurry pump spare parts manufacturer 【high quality centrifual slurry pump spare parts manufacturer】

Read Morehow-does-a-dredge-pump-work

high quality centrifual slurry pump spare parts manufacturer...

high quality centrifual slurry pump spare parts manufacturer 【high quality centrifual slurry pump spare parts manufacturer】

Read More

Popular articles

- One of the most frequently asked questions from our team of pump experts is: How do I pump slurry?xa0With this in mind, our team of experts have provided a useful guide to pumping slurry.

- how-does-a-dredge-pump-work

- Compared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

- The impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

- Slurry Pump

- A , slurry pump, is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

Latest articles

-

Again, to meet life cycle cost considerations, pumps should be equipped with large diameter impellers for lower operating speeds and longer wear life, as well as field replaceable rubber liners that can be bolted on for quick maintenance. In a typical coal-fired power plant, two to five pumps will be used in each spray tower.

-

>Slurry Pump

-

Fine-grained sand can be extremely abrasive and typically wears slurry pumps quickly. Characteristics of coarse aggregates that can affect pump performance are size, shape and surface texture, as well as gradual changes in particle size, while fine materials can create excessive friction in the pipe.

-

Applications

-

reduce the discharge pressure of the pump to the lowest possible point, and.

-

Slurry pump seals

Links

- In conclusion, floor marking tape is a must-have tool for anyone looking to enhance workplace organization and safety. Its versatility, durability, and ability to convey important information make it an invaluable asset in a wide range of industries. By investing in high-quality floor marking tape, businesses can create a more efficient, productive, and safe working environment for their employees and customers alike.

- Installation of Waterproof Butyl Rubber Aluminium Foil Tape is quick and easy. Simply clean and dry the surface before applying the tape. Press the tape firmly onto the surface and smooth out any air bubbles or wrinkles. The strong adhesive will create a tight seal that will last for years to come.

- The use of cloth for this type of tape is not arbitrary; it's chosen for its strength and ability to withstand the wear and tear of everyday use. The weave of the cloth allows the tape to be flexible but durable, making it ideal for wrapping around uneven surfaces or sharp corners without tearing. Additionally, the porous nature of the fabric enables it to breathe, which is crucial in preventing the build-up of heat that could otherwise degrade the insulation over time.

- In addition to its waterproof properties, Flex Tape White 8 x 5 is also resistant to extreme temperatures, making it ideal for use in outdoor applications. It can withstand both hot and cold temperatures, making it suitable for use in environments where other tapes may fail. This makes it a versatile solution for a wide range of repair and maintenance projects.

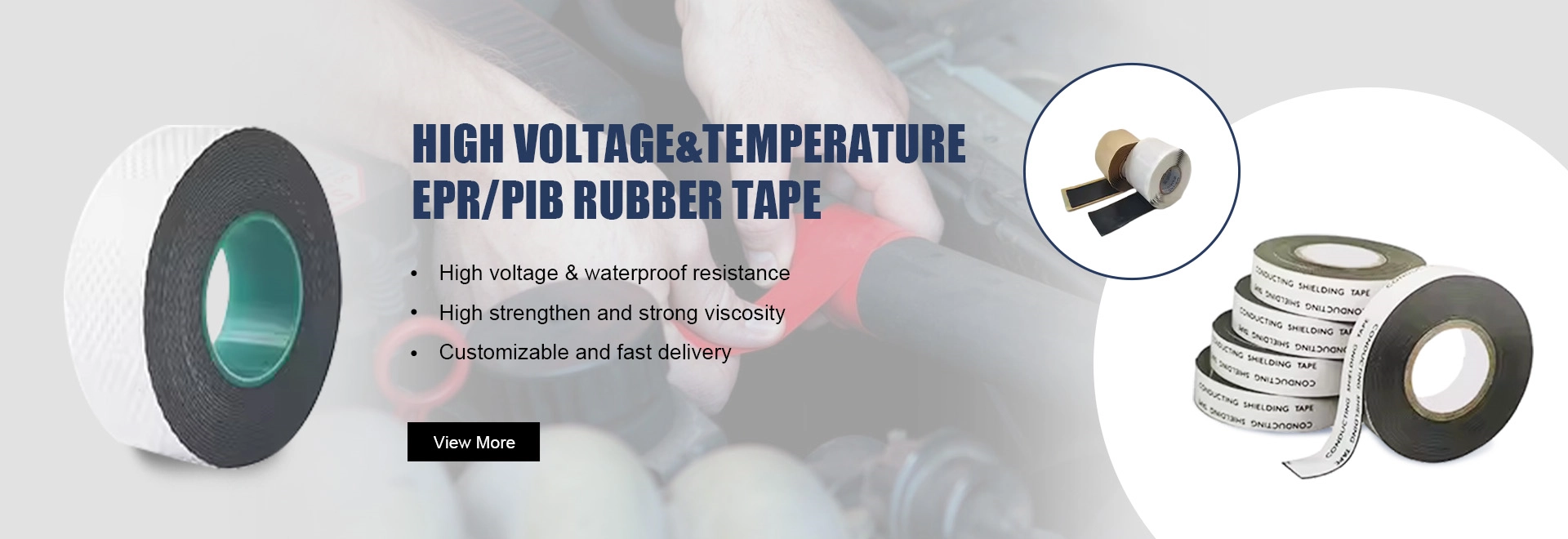

- High voltage rubber tape is made from a unique combination of materials, including synthetic rubber, which grants it its flexibility, and various insulating compounds that enhance its dielectric strength. The tape is typically thicker and more durable than regular electrical tape, making it suitable for applications where standard tape would quickly degrade or fail.

The Importance of Temporary Floor Marking Tape in Various Environments

Here at Swift, we stock a number of different electrical tapes. Some are adhesive, some are not and somewhere in the middle are our self-fusing tapes. These don't stick to surfaces but they do stick to themselves.

Overall, insulating tape is a versatile tool that serves a variety of purposes in the electrical and crafting industries. Whether it's protecting wires from electrical hazards or adding a pop of color to a project, insulating tape is an essential item to have on hand. With its affordability and ease of use, insulating tape is a must-have tool for anyone working with electrical systems or looking to get creative with their crafts.

Electrical Applications

One of the most significant advantages of self-bonding rubber tape is its ease of use. Unlike traditional tapes that require a smooth surface and adhesive to stick, rubber tape utilizes a pressure-sensitive capability that allows it to bond to itself upon contact. This property means that users can quickly wrap the tape around an object, and as they stretch it, the tape will adhere to itself, creating a tight and secure seal. This feature is especially beneficial in situations where time is of the essence and quick fixes are needed.

In addition to clear adhesive and magnetic tape, there are also specialized types of splicing tape designed for specific purposes

. For example, there is pressure-sensitive tape that is used in high-speed film editing machines to ensure quick and accurate splicing. There is also perforated tape that is used in conjunction with splicing equipment to create precise cuts in the film.Look closely at this tape and you'll see it has a tapered design. This is so that when it is applied with 50% overwrap (the green centreline helps with this) you end up with a smooth finish and less overall bulk.

Choosing high-grade tapes can increase cable longevity because they are highly durable, tightly sealed, and prevent corrosion. Reflect on your network’s environment to determine which grade will be necessary.

Additionally, proper installation and maintenance of electrical systems can help reduce the risk of electrical tape fires by ensuring that wires and components are properly insulated and that any damage or wear to the insulation is promptly addressed Additionally, proper installation and maintenance of electrical systems can help reduce the risk of electrical tape fires by ensuring that wires and components are properly insulated and that any damage or wear to the insulation is promptly addressed

Additionally, proper installation and maintenance of electrical systems can help reduce the risk of electrical tape fires by ensuring that wires and components are properly insulated and that any damage or wear to the insulation is promptly addressed Additionally, proper installation and maintenance of electrical systems can help reduce the risk of electrical tape fires by ensuring that wires and components are properly insulated and that any damage or wear to the insulation is promptly addressed electrical tape fire resistant.

electrical tape fire resistant.The application process of Flex Tape is straightforward, adding to its appeal. To use, simply cut the desired length, peel off the backing, and press it firmly onto the surface needing repair. It’s advisable to clean the area to ensure maximum adhesion. Once applied, Flex Tape immediately begins to bond, and in most cases, further reinforcement is not necessary. This ease of use makes it accessible for individuals without extensive DIY experience while still appealing to seasoned professionals.

(1) The thermal stability is 180 ℃. At this temperature, the product can be used safely for more than 10 years, saving many after-sales troubles;