best pump for lime slurry manufacturers

Latest articles

Choosing the right , slurry pump, for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the , slurry pump supplier, will share them with you.+

best pump for lime slurry manufacturers...

best pump for lime slurry manufacturers 【best pump for lime slurry manufacturers】

Read MoreIt is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

best pump for lime slurry manufacturers...

best pump for lime slurry manufacturers 【best pump for lime slurry manufacturers】

Read MoreSlurry Pump

best pump for lime slurry manufacturers...

best pump for lime slurry manufacturers 【best pump for lime slurry manufacturers】

Read MoreConsider the following.

best pump for lime slurry manufacturers...

best pump for lime slurry manufacturers 【best pump for lime slurry manufacturers】

Read MoreThe slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

best pump for lime slurry manufacturers...

best pump for lime slurry manufacturers 【best pump for lime slurry manufacturers】

Read MoreA quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

best pump for lime slurry manufacturers...

best pump for lime slurry manufacturers 【best pump for lime slurry manufacturers】

Read MoreExpertise and experience

best pump for lime slurry manufacturers...

best pump for lime slurry manufacturers 【best pump for lime slurry manufacturers】

Read MoreThe size and nature of the solids in the liquid: The size and nature will affect the amount of physical wear on the pump and its components, and whether the solids will pass through the pump without being damaged.

best pump for lime slurry manufacturers...

best pump for lime slurry manufacturers 【best pump for lime slurry manufacturers】

Read MoreAll manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

best pump for lime slurry manufacturers...

best pump for lime slurry manufacturers 【best pump for lime slurry manufacturers】

Read MoreHorizontal centrifugal pumps are commonly used for slurry service, but vertical and other types of pumps are better suited to certain specific applications. Centrifugal pumps for handling slurries have features tailored to specific services that reflect the corrosive or abrasive nature of the slurry and the concentration of solids. These may include the choice of materials, the use of liners or even different drive sizes.

best pump for lime slurry manufacturers...

best pump for lime slurry manufacturers 【best pump for lime slurry manufacturers】

Read More

Popular articles

- When pumping slurry in wet sand applications, we must evaluate the abrasive particles flowing through the piping and then assess how they affect the slurry pump. If the pump is lined with poor quality rubber, the particles will not rebound effectively and, as a result, the rubber will begin to break down. The air shavings then begin to accelerate and negatively impact the efficiency of the pump, often leading to turbulence.

- Slurry pump design

- There is a science behind the design of a , slurry pump, , based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

- Slurries are divided into two main categories: non-settling or settling. Non-settling slurries consist of very fine particles, giving the illusion of increased apparent viscosity. These slurries usually have low wear characteristics, but require very careful consideration when selecting the right pump, as they behave differently from ordinary liquids.

- Choosing the right pump for your slurry is critical to getting the most out of it. Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear caused by abrasive slurries. Compared to low-viscosity liquid pumps, target=_blank title=Slurry Pump>slurry pumps are typically larger and often require more horsepower to operate because they are less efficient. Bearings and shafts must also be more robust and durable.

- Customised solutions

Latest articles

-

A slurry pump is a mechanical device used for the pressure-driven transfer of a fluid mixture (aka slurry). The fluid mixture consists largely of water as a liquid and solids as minerals, sand, gravel, human excrement, drilling mud or mostly crushed material.

-

Discharge ports can be placed at 45 degree intervals and oriented in up to 8 different positions depending on your needs.

-

The slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

-

Some quench seals are planned to replace the tight fitting outlet restriction with a secondary seal and a top outlet that can be piped to capture the used quench fluid and drain it from the rotating assembly. However the principle is the same, we try to cool the seal rather than flush it in any way.

-

Slurry Pump selection

-

target=_blank title=Rubber Liner Pumps>Rubber liner pumps have been used for nearly a century to protect plants and equipment from wear and retain their place as the wear material of choice for pumping and separating fine-grained slurries.

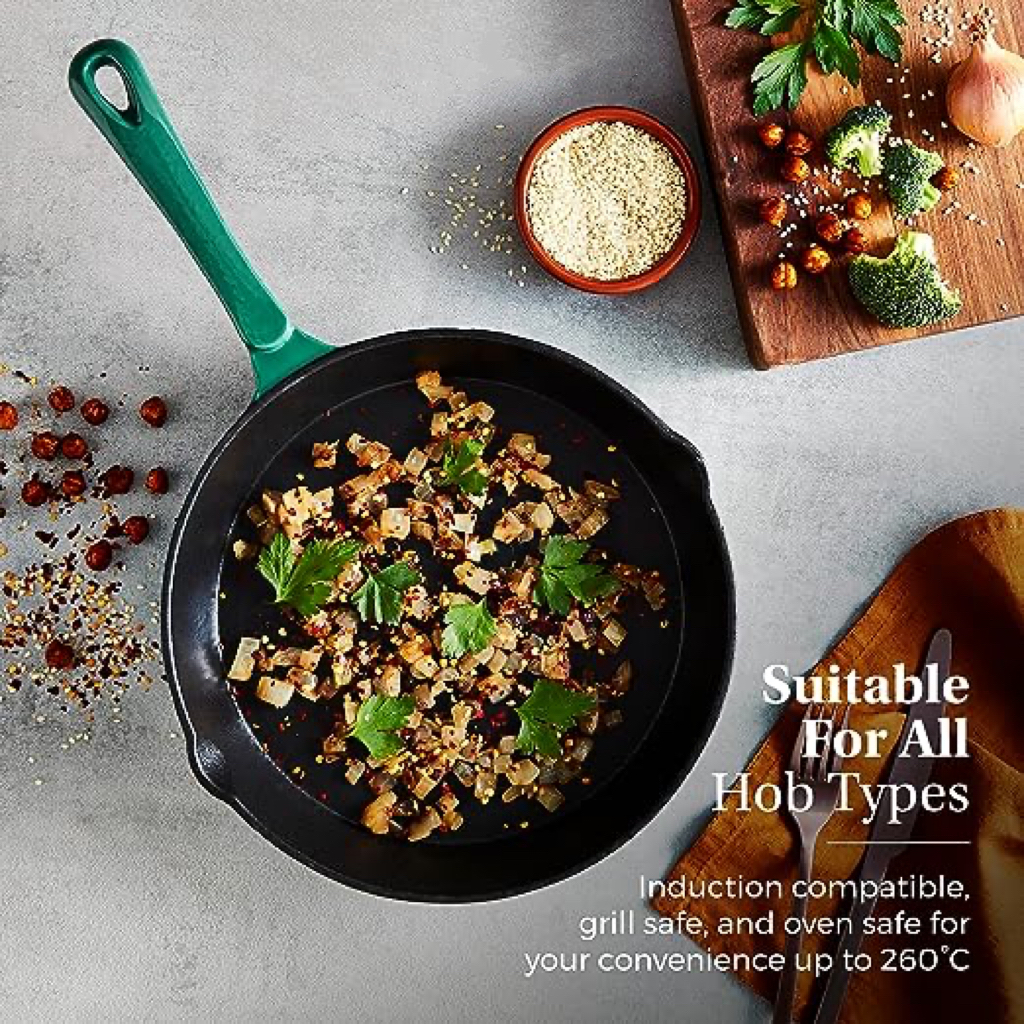

Offering excellent heat conduction, aluminum frying pans dissipate heat quickly for efficient, even cooking. Uncoated aluminum frying pans have a stick-, rust-, and corrosion-resistant surface and should only be used to cook low-acidic foods since acidic foods, such as tomato paste, citrus, and vinegar, react with aluminum and can alter the flavor of your food. Many professional aluminum frying pans are hard-anodized or feature a non-stick coating to make them non-reactive. Aluminum pans are not compatible with induction cooktops since aluminum is not magnetic.

Home Cooking: Black cast iron griddles and grill pans are popular in home kitchens, offering a convenient and effective way to achieve professional-quality searing, grilling, and cooking results. They are suitable for a variety of cooking techniques and are easy to maintain.

This patina becomes a canvas for flavor, where every meal can pick up subtle hints of what has come before, adding depth and complexity to your dishes This patina becomes a canvas for flavor, where every meal can pick up subtle hints of what has come before, adding depth and complexity to your dishes

This patina becomes a canvas for flavor, where every meal can pick up subtle hints of what has come before, adding depth and complexity to your dishes This patina becomes a canvas for flavor, where every meal can pick up subtle hints of what has come before, adding depth and complexity to your dishes small cast iron frying pan.

small cast iron frying pan.

Finally, a frying pan is a flexible cooking vessel that you can use for sautéing, grilling, and baking, among other things.

In addition to size differences, Dutch ovens are available in a variety of materials, such as cast iron, aluminum, and ceramic. Generally speaking, cast iron pots are the main ones. Cast iron Dutch ovens are known for their excellent heat retention and durability, making them ideal for long, slow cooking.

Typically made by adding a non-stick coating to aluminum pans, non-stick frying pans are ideal for cooking delicate foods with a tendency to stick, such as fish, fried eggs, and pancakes. The non-stick coating limits the amount of oils and fats needed to cook food and makes cleanup a breeze since your food won't stick to the pan. Non-stick pans are best used in low to medium heat settings to extend the coating's life. Using a non-stick pan in high-heat applications can damage the coating and cause it to smoke, peel, or flake.

On the other hand, if you need a large enameled pot to cater to larger groups or to cook more food, there are many options to choose from. The large enamel pot is perfect for making stews, casseroles, and one-pot meals for the whole family. They're also great for boiling pasta, making stock, or preparing large batches of soup.

non stick reversible griddle. Some models of the non-stick reversible griddle come equipped with advanced features such as adjustable temperature control, allowing you to set the perfect heat for whatever you're cooking. Others might be designed to fold in half, making storage a cinch in even the most cramped of kitchens. And for the environmentally conscious, many are constructed from materials that promote sustainability and longevity.

non stick reversible griddle. Some models of the non-stick reversible griddle come equipped with advanced features such as adjustable temperature control, allowing you to set the perfect heat for whatever you're cooking. Others might be designed to fold in half, making storage a cinch in even the most cramped of kitchens. And for the environmentally conscious, many are constructed from materials that promote sustainability and longevity.The expense—and lack of induction compatibility—can be a deal breaker for some cooks when it comes to copper pans.

Enamel Pots For Sale

After cooking, it's crucial to properly clean and maintain your cast iron skillet. While some people may be tempted to use soap and water, it's best to avoid harsh detergents as they can wash away sauce from the cast iron grill pan. Instead, use a brush or sponge to gently scrub the pot with warm water. After cleaning, dry the cast iron grill pan thoroughly and apply a light coat of oil to prevent rust.

repairing chipped enamel cookware. Mix the putty as directed, then gently press it into the chip. Smooth the surface with a plastic spatula or your finger (ensuring it's clean and wet to prevent sticking). Once set, sand the area lightly with fine-grit sandpaper to blend it with the surrounding enamel.

repairing chipped enamel cookware. Mix the putty as directed, then gently press it into the chip. Smooth the surface with a plastic spatula or your finger (ensuring it's clean and wet to prevent sticking). Once set, sand the area lightly with fine-grit sandpaper to blend it with the surrounding enamel.