slurry pump price supplier

Latest articles

how-does-a-dredge-pump-work

slurry pump price supplier...

slurry pump price supplier 【slurry pump price supplier】

Read MoreHow to Choose a Dredging Pump or Slurry Pump

slurry pump price supplier...

slurry pump price supplier 【slurry pump price supplier】

Read MoreTL FGD Pump

slurry pump price supplier...

slurry pump price supplier 【slurry pump price supplier】

Read MorePumping slurry can present some challenges and problems, but with proper engineering and equipment selection, you can experience years of trouble-free operation. It's important to work with a qualified engineer when selecting a slurry pump, because slurry can wreak havoc on a pump if not selected properly.

slurry pump price supplier...

slurry pump price supplier 【slurry pump price supplier】

Read MoreSlurry pump construction materials

slurry pump price supplier...

slurry pump price supplier 【slurry pump price supplier】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

slurry pump price supplier...

slurry pump price supplier 【slurry pump price supplier】

Read MoreMake sure you follow the basic rules of pump piping.

slurry pump price supplier...

slurry pump price supplier 【slurry pump price supplier】

Read MoreCarbon transfer

slurry pump price supplier...

slurry pump price supplier 【slurry pump price supplier】

Read MoreIf you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

slurry pump price supplier...

slurry pump price supplier 【slurry pump price supplier】

Read MorePump selection for FGD

slurry pump price supplier...

slurry pump price supplier 【slurry pump price supplier】

Read More

Popular articles

- Aier Machinery's team of consultants are on hand to provide you with a solution to your needs. Whether you are planning to purchase a slurry pump or need spare parts for an existing pump, we will help you determine your needs and provide advice on fine-tuning your equipment to your specific application.

- The Difference Between Flushing And Quenching in Slurry Pump Seals

- BCT Ceramic Slurry Pumps

- - Pumping the final product in a process

- - Smaller, more efficient tank - Because the motor is cooled by the surrounding liquid, the submersible slurry pump can be started up to 30 times per hour, resulting in a smaller, more efficient tank.

- Auxiliary equipment

Latest articles

-

Especially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

-

Carbon transfer

-

Compared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

-

How much solids damage can the customer tolerate?

-

What is a dredging pump?

-

What is slurry?

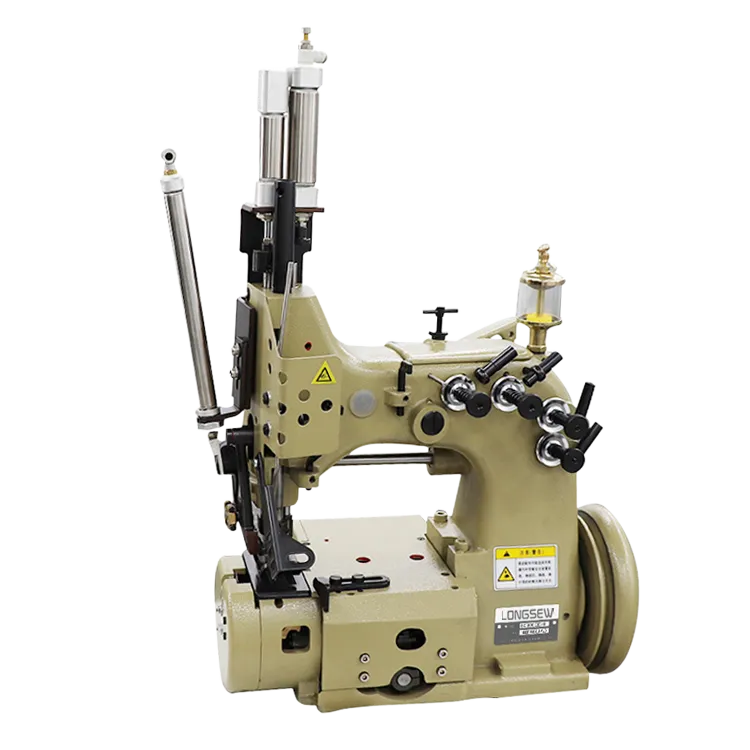

What is a Commercial Zig Zag Sewing Machine?

The Versatility and Utility of the 2% Needle Walking Foot Sewing Machine

Quilting Made Easier

A heavy duty sewing machine is a valuable addition to any crafter’s arsenal. With its robust capabilities and versatility, it opens up a world of creative possibilities. By understanding the features, selecting the right machine, and mastering the techniques and tricks, you can elevate your crafting projects to new heights. Whether you’re working with thick fabrics, tackling ambitious upholstery projects, or venturing into new creative territories, a heavy duty sewing machine will be your trusted companion. So, gear up, explore the tips and tricks shared in this guide, and embark on a crafting journey that knows no bounds.

When it comes to sewing and stitching machines, one of the most powerful and versatile options available is the long arm stitching machine. This specialized machine is designed for larger projects and offers a variety of benefits that make it an essential tool for serious sewers and quilters.

A bag seaming machine is a specialized piece of equipment used to join the edges of bags, usually made from materials like plastic, woven polypropylene, paper, or cloth. These machines employ different seaming techniques, including heat sealing, ultrasonic sealing, and stitching, to create strong and durable seals that can withstand various handling and transportation conditions.

Understanding Single Needle Sewing Machines

The position of the needle as it enters and exits the leather is fundamental to achieving secure stitches. Ideally, you should hold the leather firmly but not excessively tight, as this can distort the material. When inserting the needle, aim to enter the leather at a 90-degree angle to maintain consistent stitch depth. This angle not only ensures a cleaner penetration but also helps create uniform spacing between stitches.

positioning needle for hand sewing leather

5. Warranty and Support A good warranty can provide peace of mind. Additionally, ensure that customer support is readily available for any questions or issues that may arise.

Key Features

1. Increased Efficiency Using appropriate strong needles can enhance sewing efficiency. Needles designed for heavy fabrics can move through the material with ease, reducing the risk of breakages or skipped stitches. This efficiency is particularly important for professional seamstresses or those who undertake large sewing projects.

The applications of double needle walking foot industrial sewing machines are vast. In the garment industry, they are commonly used for sewing hems, seams, and decorative stitches on a wide range of clothing items, from shirts to jackets. In upholstery, these machines are invaluable for creating strong seams in sofas, chairs, and other furniture pieces that require durability. Additionally, they find utility in leather goods production, where the quality of stitching is paramount for both aesthetic and functional reasons.

Factors to Consider When Buying a Carpet Overlocking Machine

In the world of industrial sewing, the quest for efficiency and durability has led to the development of specialized machines that can handle the most challenging materials. Among these, the compound feed heavy duty sewing machine stands out as a vital tool for both manufacturers and hobbyists alike. This article delves into the features, benefits, and applications of this remarkable sewing machine.

Conclusion

The Double Tailor Machine Revolutionizing Fashion Production

industrial sewing machine needles for leather. The size of the needle refers to the diameter of the needle shaft, with larger numbers indicating thicker needles. For sewing leather, it is recommended to use needles with sizes ranging from 14 to 18, as these sizes are strong enough to penetrate through the material without causing damage.

Arm sewing can be used to create a wide range of projects, from simple repairs and alterations to more complex garments and accessories. Whether you are a beginner or an experienced sewer, arm sewing offers a fun and rewarding way to express your creativity and enhance your sewing skills.

Investment vs. Cost