slurry pump for vapor blasting suppliers

Latest articles

Submersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

slurry pump for vapor blasting suppliers...

slurry pump for vapor blasting suppliers 【slurry pump for vapor blasting suppliers】

Read MoreCorrosiveness of the slurry

slurry pump for vapor blasting suppliers...

slurry pump for vapor blasting suppliers 【slurry pump for vapor blasting suppliers】

Read MoreHow much solids damage can the customer tolerate?

slurry pump for vapor blasting suppliers...

slurry pump for vapor blasting suppliers 【slurry pump for vapor blasting suppliers】

Read MoreThe rule of thumb for setting the water pressure is the same when using the pack box, whether flushing. Mud pump shut-off pressure plus 10% or plus 20 psi, whichever is greater. However, the flow rate is set differently.

slurry pump for vapor blasting suppliers...

slurry pump for vapor blasting suppliers 【slurry pump for vapor blasting suppliers】

Read MoreSlurry pump impeller, is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

slurry pump for vapor blasting suppliers...

slurry pump for vapor blasting suppliers 【slurry pump for vapor blasting suppliers】

Read MoreSlurry Pump

slurry pump for vapor blasting suppliers...

slurry pump for vapor blasting suppliers 【slurry pump for vapor blasting suppliers】

Read MoreDesire for higher efficiency than centrifugal pumps

slurry pump for vapor blasting suppliers...

slurry pump for vapor blasting suppliers 【slurry pump for vapor blasting suppliers】

Read MoreTo reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

slurry pump for vapor blasting suppliers...

slurry pump for vapor blasting suppliers 【slurry pump for vapor blasting suppliers】

Read MoreSlurry pump impeller, is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

slurry pump for vapor blasting suppliers...

slurry pump for vapor blasting suppliers 【slurry pump for vapor blasting suppliers】

Read MoreIf you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

slurry pump for vapor blasting suppliers...

slurry pump for vapor blasting suppliers 【slurry pump for vapor blasting suppliers】

Read More

Popular articles

- It is important that the pump you choose has components that will not wear out from abrasive slurries.

- >Slurry Pump

- The FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

- With the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

- Applications of Rubber Lined Slurry Pumps

- Better safety

Latest articles

-

Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

-

As described below, there are several >types of pumps that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

-

- Pumping media where abrasive particles are present

-

We know that the right rubber and ceramic liners work very well. They also last longer and can withstand more demanding use. They can also be replaced, thereby extending the life of the pump while reducing operating costs. You can also customise your pump with a variety of ceramic parts, including bushings, pump housings, impellers, wet ends and even seals.

-

Fewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - typically 2-5 vanes.

-

Traditionally, centrifugal pumps are used to pump highly abrasive slurries. Centrifugal pumps use the force generated by the rotating impeller to impinge kinetic energy into the slurry.

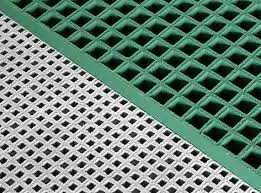

In applications where the grating may need more support than that offered by the molded in recesses at the top of the flume, Openchannelfow installes tube supports at the inlet / outlet of the flume for the grating to sit on to provide additional support.

Traditional drills can be hazardous due to the risk of kickback, where the bit unexpectedly rotates back towards the operator Traditional drills can be hazardous due to the risk of kickback, where the bit unexpectedly rotates back towards the operator

Traditional drills can be hazardous due to the risk of kickback, where the bit unexpectedly rotates back towards the operator Traditional drills can be hazardous due to the risk of kickback, where the bit unexpectedly rotates back towards the operator long drill bit extension. This can result in serious injuries if proper precautions are not taken. However, with the long drill bit extension, operators can maintain a safe distance from the drilling area, reducing the risk of injury and improving overall workplace safety.

long drill bit extension. This can result in serious injuries if proper precautions are not taken. However, with the long drill bit extension, operators can maintain a safe distance from the drilling area, reducing the risk of injury and improving overall workplace safety.

thread tap drill bits.

These bits are typically made from high-quality materials, such as carbide or cobalt, which ensures long-lasting performance and reliability These bits are typically made from high-quality materials, such as carbide or cobalt, which ensures long-lasting performance and reliability

These bits are typically made from high-quality materials, such as carbide or cobalt, which ensures long-lasting performance and reliability These bits are typically made from high-quality materials, such as carbide or cobalt, which ensures long-lasting performance and reliability reversible drill bit. This means that a reversible drill bit can withstand the rigors of frequent use and continue to provide consistent results over time.

reversible drill bit. This means that a reversible drill bit can withstand the rigors of frequent use and continue to provide consistent results over time.

Fiberglass, on the other hand, is highly resistant to corrosion and can withstand exposure to these harsh chemicals without any significant degradation Fiberglass, on the other hand, is highly resistant to corrosion and can withstand exposure to these harsh chemicals without any significant degradation

Fiberglass, on the other hand, is highly resistant to corrosion and can withstand exposure to these harsh chemicals without any significant degradation Fiberglass, on the other hand, is highly resistant to corrosion and can withstand exposure to these harsh chemicals without any significant degradation