single stage vertical slurry pump

Latest articles

Will solids size pass through the pump?

single stage vertical slurry pump...

single stage vertical slurry pump 【single stage vertical slurry pump】

Read MoreTypes of slurry pump installation.

single stage vertical slurry pump...

single stage vertical slurry pump 【single stage vertical slurry pump】

Read More>Slurry Pump

single stage vertical slurry pump...

single stage vertical slurry pump 【single stage vertical slurry pump】

Read MoreAll products are mainly supplied to environmental protection, wastewater treatment, urban water supply and drainage, mine, metallurgy, coal, petrochemical, building material, thermal power FGD, river dredging, tailing disposal and other fields.

single stage vertical slurry pump...

single stage vertical slurry pump 【single stage vertical slurry pump】

Read MoreOne of the most frequently asked questions from our team of pump experts is: How do I pump slurry? With this in mind, our team of experts have provided a useful guide to pumping slurry.

single stage vertical slurry pump...

single stage vertical slurry pump 【single stage vertical slurry pump】

Read MoreSlurry Pump

single stage vertical slurry pump...

single stage vertical slurry pump 【single stage vertical slurry pump】

Read MoreThere are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

single stage vertical slurry pump...

single stage vertical slurry pump 【single stage vertical slurry pump】

Read MoreFor example.

single stage vertical slurry pump...

single stage vertical slurry pump 【single stage vertical slurry pump】

Read MoreAier Machinery Hebei Co., Ltd. is a large-scale professional >slurry pumps manufacturer, gravel pumps, dredge pumps, sewage pumps and clean water pumps in China.

single stage vertical slurry pump...

single stage vertical slurry pump 【single stage vertical slurry pump】

Read MoreThe first major requirement for >slurry pumps is to provide adequate service life. The erosive and corrosive effects of slurries, such as the impact of high velocity flow of liquid/solid mixtures, can be really challenging. In many applications, some of the solids in the mixture are larger than the particles normally specified; therefore, the pump should be able to pass through them without causing any damage or operational problems.

single stage vertical slurry pump...

single stage vertical slurry pump 【single stage vertical slurry pump】

Read More

Popular articles

Latest articles

-

reduce the discharge pressure of the pump to the lowest possible point, and.

-

Positive displacement slurry pumps with limited capacity to deliver high head are used to pump slurry through pipes with very high solids concentrations.

-

The Company Adopts Advanced Computer Aided Engineering Software

-

Choosing the right material for a slurry pump is another key process in determining the right pump for handling slurry. If the slurry is highly abrasive with neutral pH, then the best material of construction is Hi-Chrome. this metallurgy has the highest Brinell hardness and can withstand the abrasiveness of the slurry.

-

sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

-

Fewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - typically 2-5 vanes.

Ultimately, the question “Are there more doors or wheels?” may not have a definitive answer. It opens up discussions about consumption, manufacturing, cultural significance, and the impact of design in our daily lives. What is clear is that both play crucial roles in shaping our environment and experiences.

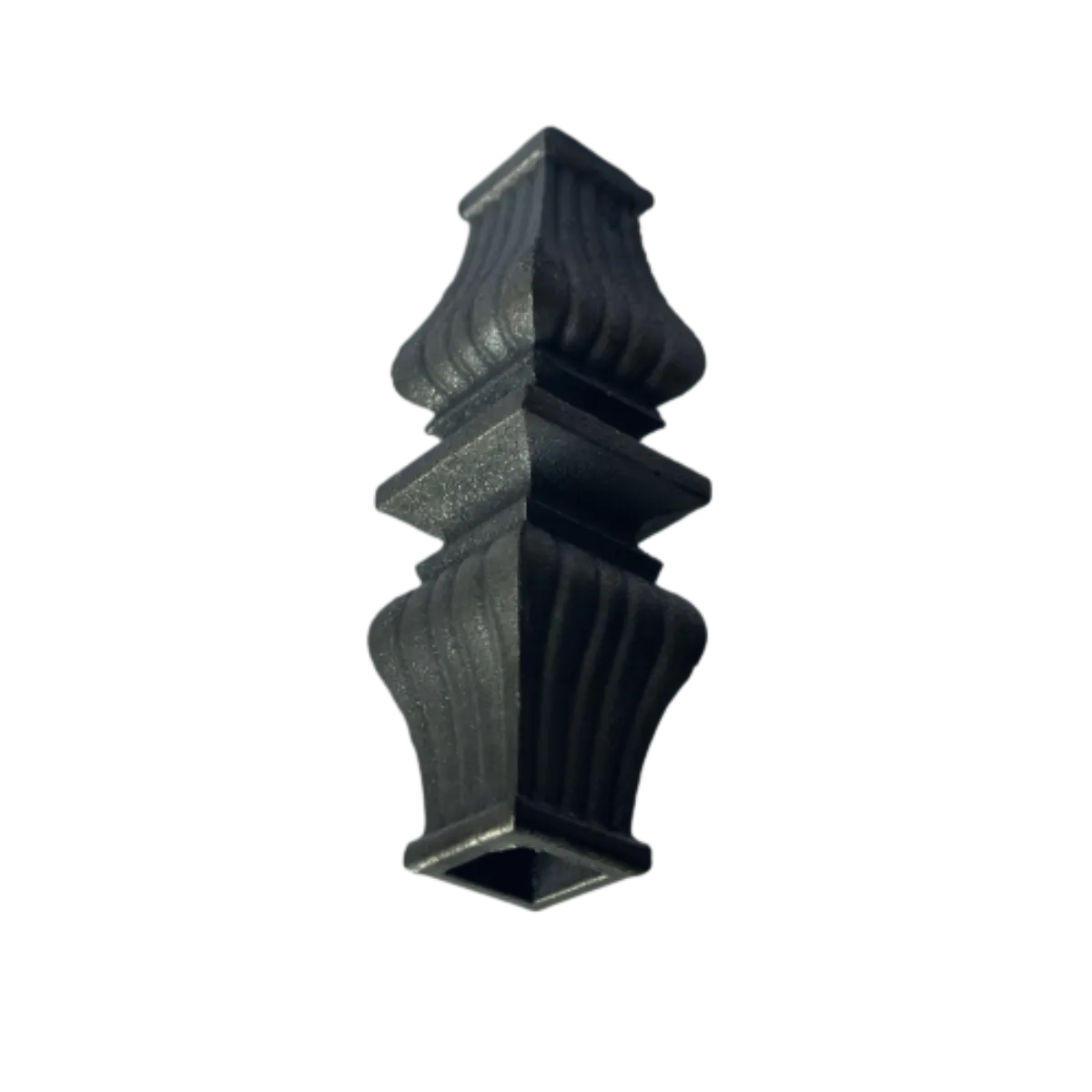

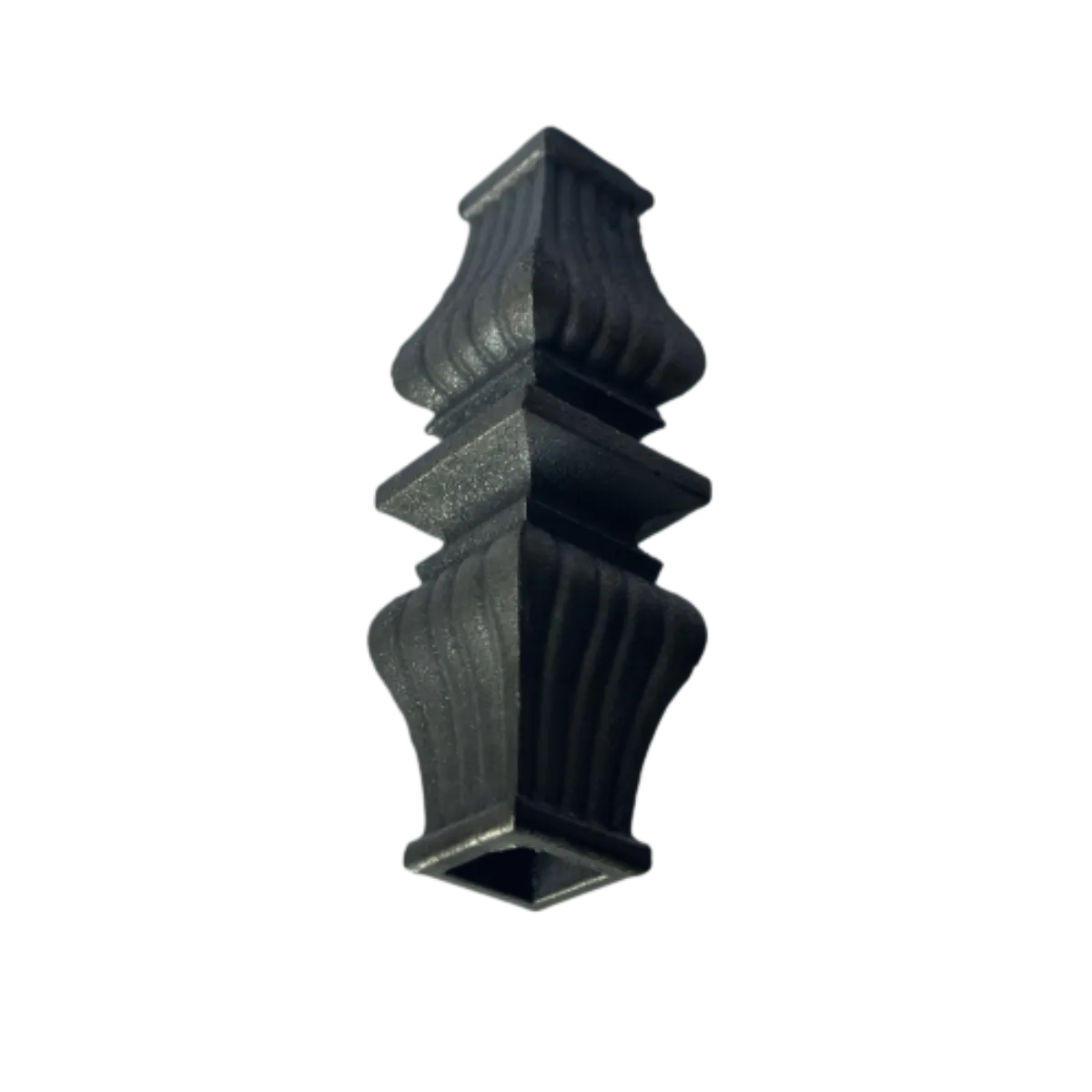

Connecting the posts are the horizontal rails. These parts provide structure and maintain the integrity of the fence. Wrought iron fences typically consist of two horizontal rails—top and bottom. The top rail is often wider than the bottom, providing a finished look and added stability. Rails can also be designed with intricate patterns, seamlessly blending function with artistic expression.

Enhance Security and Style: Door and Window Hardware Solutions

To ensure that the rollers of your aluminum sliding windows remain in good working condition, regular maintenance is essential

. Here are some tipsWHAT ARE THE TYPES OF ALUMINIUM WINDOWS?

Types of aluminum window profiles

The door sliding roller is a small but crucial part that allows the door to glide along the track effortlessly. It is typically made of durable materials such as metal or nylon, and is designed to withstand the weight of the door as it slides back and forth. The roller is attached to the bottom of the door and fits securely into the track, ensuring that the door moves smoothly and quietly.

Spacer Bar: A component that separates the two glass panes in a double-glazed window. It may be filled with desiccant to absorb any moisture between the panes.

Powder Coated Aluminium Profiles

Let’s talk numbers for a moment. After all, one of the most commonly asked questions we see is in regard to the wrought iron vs aluminum fence cost.

However, shorter spears are more maneuverable and easier to handle, making them a better option for hunting smaller game However, shorter spears are more maneuverable and easier to handle, making them a better option for hunting smaller game

However, shorter spears are more maneuverable and easier to handle, making them a better option for hunting smaller game However, shorter spears are more maneuverable and easier to handle, making them a better option for hunting smaller game best hunting spears.

best hunting spears.The bridge cutoff aluminum alloy profiles have strong air tightness, water tightness, heat insulation and sound insulation, and are suitable for various specific applications in the door and window industry.

Aluminum is also more cost-effective upfront, but this may vary based on the quality and style you choose. It offers a modern look but is versatile enough to complement a wide range of property styles. Now, let’s introduce the other half of the aluminum vs wrought iron fence debate.

Once detached, dispose of the old wheels responsibly Once detached, dispose of the old wheels responsibly

Once detached, dispose of the old wheels responsibly Once detached, dispose of the old wheels responsibly wheel replacement for sliding screen door.

wheel replacement for sliding screen door.Furthermore, iron gates can be customised with various finishes such as powder coating, galvanising, or even antique patinas. These treatments not only enhance the aesthetic appeal but also protect the iron from rust and corrosion, ensuring the gate maintains its beauty and functionality over time.

Customization and Artistry

Standard packaging+additional paper

Plus, aluminum is a tough material that maintains its brand-new look for longer and requires little to no maintenance on your part. When you partner with an experienced aluminum fence installer, you can expect a painless installation procedure along the way too.

1. Remove Obstructions Before making any adjustments, ensure that the area around the sliding door is clear. This includes taking down any curtains or blinds that may interfere with your work.

adjusting rollers on sliding door

When selecting wheels for your sliding door track, consider the following factors

Metal storage lock boxes also come in various sizes, styles, and colors, allowing users to choose the perfect option for their specific needs. From small, portable boxes to larger, more expansive units, there is a lock box ideal for every situation. Some manufacturers even offer customizable solutions, allowing businesses to add their branding or unique designs, which can help with quick identification and enhance the overall aesthetic.