china anti abrasive sand slurry pump factory

Latest articles

In dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

china anti abrasive sand slurry pump factory...

china anti abrasive sand slurry pump factory 【china anti abrasive sand slurry pump factory】

Read MoreAier Machinery's team of consultants are on hand to provide you with a solution to your needs. Whether you are planning to purchase a slurry pump or need spare parts for an existing pump, we will help you determine your needs and provide advice on fine-tuning your equipment to your specific application.

china anti abrasive sand slurry pump factory...

china anti abrasive sand slurry pump factory 【china anti abrasive sand slurry pump factory】

Read MoreSelecting the right pump for slurries is critical to get the most bang for your buck. Basic pump components, such as the impeller size and design, material of construction, and discharge configurations must be considered to ensure the pump will hold up against the wear caused by an abrasive slurry. Slurry pumps are generally larger in size when compared to low-viscosity liquid pumps and usually require more horsepower to operate because they're less efficient. Bearings and shafts must be more rugged and rigid as well.

china anti abrasive sand slurry pump factory...

china anti abrasive sand slurry pump factory 【china anti abrasive sand slurry pump factory】

Read More>Slurry Pump

china anti abrasive sand slurry pump factory...

china anti abrasive sand slurry pump factory 【china anti abrasive sand slurry pump factory】

Read MoreThe slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

china anti abrasive sand slurry pump factory...

china anti abrasive sand slurry pump factory 【china anti abrasive sand slurry pump factory】

Read More>Vertical Slurry Pump

china anti abrasive sand slurry pump factory...

china anti abrasive sand slurry pump factory 【china anti abrasive sand slurry pump factory】

Read MoreBetter safety

china anti abrasive sand slurry pump factory...

china anti abrasive sand slurry pump factory 【china anti abrasive sand slurry pump factory】

Read MoreIf pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

china anti abrasive sand slurry pump factory...

china anti abrasive sand slurry pump factory 【china anti abrasive sand slurry pump factory】

Read MoreOne problem with centrifugal pumps is that the velocity and shear forces within the pump may damage the slurry/solids. Typically, twin-screw pumps cause the least damage to solids in the slurry.

china anti abrasive sand slurry pump factory...

china anti abrasive sand slurry pump factory 【china anti abrasive sand slurry pump factory】

Read MoreThe terms 'flushing' and 'quench' often seem to be confused or misused when discussing seal support schemes for >slurry pumps. As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

china anti abrasive sand slurry pump factory...

china anti abrasive sand slurry pump factory 【china anti abrasive sand slurry pump factory】

Read More

Popular articles

- 3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

- What is a dredging pump?

- Step 1

- Advantages of rubber

- How Slurry Pumps Differ From Standard Pumps?

- Choosing the right , slurry pump, for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the , slurry pump supplier, will share them with you.+

Latest articles

-

Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High

-

We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

-

Our firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

-

Any type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

-

Find a professional slurry pump supplier

-

sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

Links

Wrought iron is a durable material that can withstand the elements and last for years to come. This makes it an excellent choice for fencing, as it requires minimal maintenance and will continue to look beautiful for many years.

- Rollers are essentially the wheels that allow the smooth opening and closing of the security screen door. Made from high-quality materials such as stainless steel or aluminum, they are built to withstand harsh weather conditions and resist corrosion. Their durability is essential, as a faulty roller can compromise the door's ability to lock securely, leaving your home vulnerable.

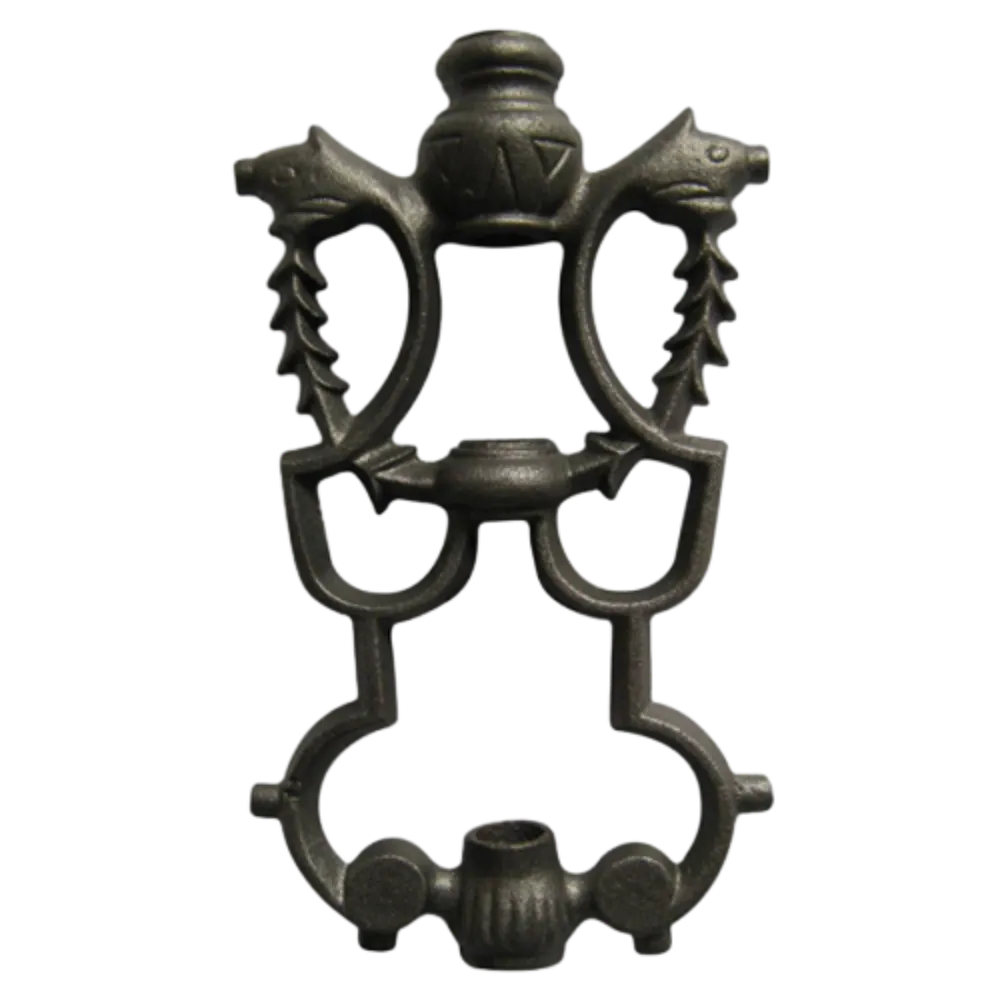

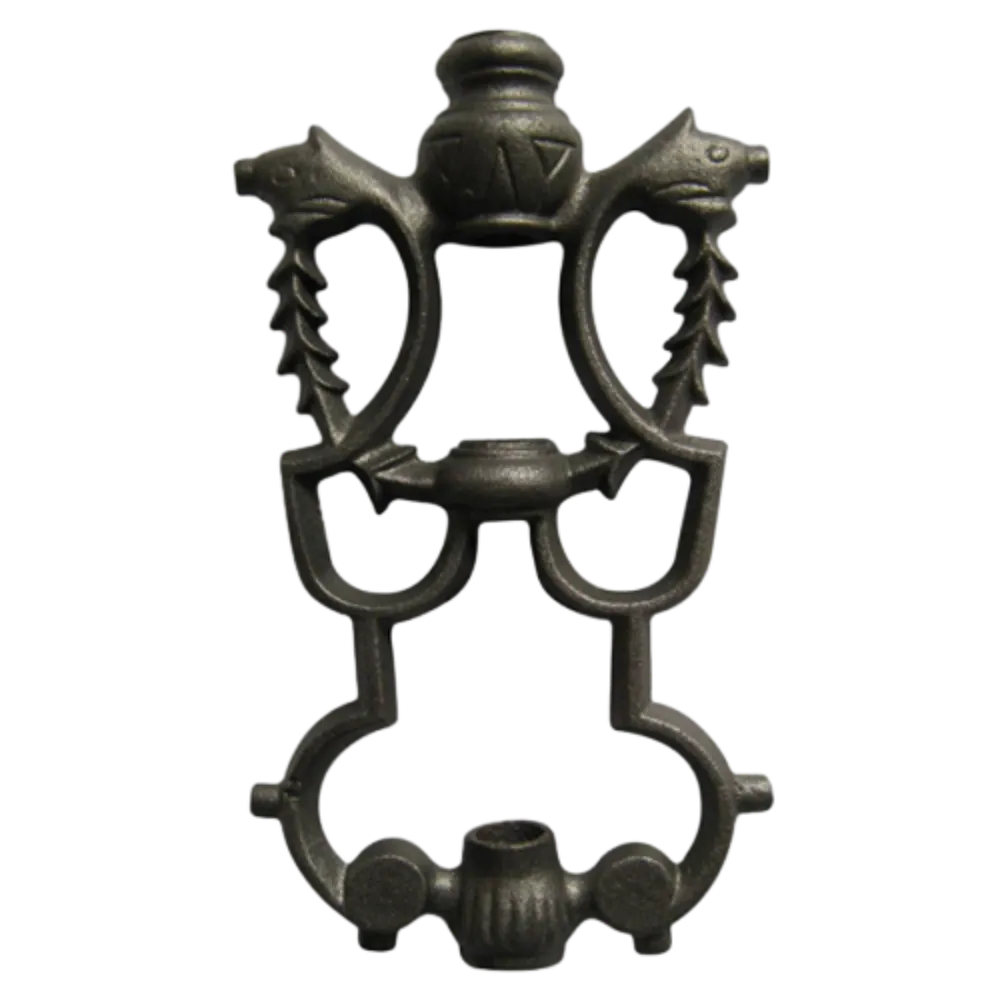

Cast iron fencing is typically chosen for its ornate and precise designs, made possible by the casting process which allows intricate patterns and shapes. This type of fencing is quite strong and can withstand significant wear. However, cast iron is technically more brittle than wrought iron: meaning it’s more likely to crack or break rather than bend if subjected to high impact or pressure.

Overall, a wrought iron gate is a stylish and secure addition to any property. Whether you are looking to enhance the beauty of your home or increase the security of your business, a wrought iron gate is a great choice. With many options available for sale, you are sure to find a gate that fits your style and budget. So why wait? Upgrade your property with a wrought iron gate today!

- Fireproof Safe A Small Yet Mighty Security Solution

- Aluminum cill profiles have become a cornerstone in the modern architectural world, offering unparalleled versatility and sophistication. These profiles are not merely linear structures; they are the embodiment of functionality meeting aesthetics, providing both structural support and visual appeal in various constructions.

- Extruded Screen Frame Profiles A Comprehensive Guide

- The Small Steel Lock Box

- When it comes to sourcing cast iron picket castings, there are a variety of suppliers and manufacturers that offer a wide selection of designs and styles to choose from. Whether you are looking for a traditional Victorian-inspired design or a more contemporary and minimalist look, there is sure to be a casting that fits your needs and budget.

- One of the main advantages of aluminum window frame extrusion profiles is their strength-to-weight ratio. Aluminum is a strong material that can support large panes of glass without adding unnecessary weight to the window frame. This allows for larger windows with thinner frames, providing a clean and modern look while maximizing natural light exposure.

I. Types of aluminum profiles for doors and windows:

- Moreover, sliding screen wheels offer versatility in design

- Decorative cast iron panels were particularly popular during the Victorian era, adorning everything from building facades to household furnishings. They were often adorned with motifs inspired by nature, such as floral arrangements, animal figures, or geometric shapes, reflecting the prevalent styles and tastes of the time. Each panel tells a story, capturing the spirit and essence of the era in which it was created.

- Changing Sliding Door Rollers A DIY Guide for Smooth Sliding Action

- Aluminium, as a material, is renowned for its strength, corrosion resistance, and lightweight properties. When utilised in window rollers, these attributes translate into windows that are not only robust but also easy to operate. The aluminium window rollers are designed to withstand harsh weather conditions, ensuring long-term performance with minimal maintenance. Their robustness also makes them ideal for high-traffic areas where durability is a prime concern.

sliding screen roller replacement. If not, adjust your purchase accordingly. Insert the new roller into the assembly slot, ensuring it fits snugly. Replace any worn-out tracks or brackets as needed. Then, reattach the roller assembly to the door with the screws, tightening them securely but not overly tight to avoid damaging the material.

sliding screen roller replacement. If not, adjust your purchase accordingly. Insert the new roller into the assembly slot, ensuring it fits snugly. Replace any worn-out tracks or brackets as needed. Then, reattach the roller assembly to the door with the screws, tightening them securely but not overly tight to avoid damaging the material.Versatile Applications

stainless steel box with lock

Aluminium Profiles Quality Test │ Raw Material

It conjures images of bygone eras when trunks and chests were used to store treasures and memories It conjures images of bygone eras when trunks and chests were used to store treasures and memories

It conjures images of bygone eras when trunks and chests were used to store treasures and memories It conjures images of bygone eras when trunks and chests were used to store treasures and memories metal box with lid and lock. In a world increasingly dominated by digital storage, this physical container serves as a tangible link to the past, preserving our belongings in a way that feels intimate and personal.

metal box with lid and lock. In a world increasingly dominated by digital storage, this physical container serves as a tangible link to the past, preserving our belongings in a way that feels intimate and personal.Incorporating Wrought Iron into Your Landscape

Selling or donating usable parts of a wrought iron fence is a sustainable way to dispose of materials that are no longer needed. First, assess which parts of the fence are in good condition and could be reused. Components like gates, panels, and decorative pieces often retain functional and aesthetic value.

cast iron ornaments.

The only real disadvantage of steel fences is that they are available in a relatively limited range of styles. That being said, the best fence installation companies will typically still be able to offer a wide range of ornamental styles and varieties to choose from.