high quality multistage slurry pump supplier

Latest articles

Settling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

high quality multistage slurry pump supplier...

high quality multistage slurry pump supplier 【high quality multistage slurry pump supplier】

Read MoreChromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

high quality multistage slurry pump supplier...

high quality multistage slurry pump supplier 【high quality multistage slurry pump supplier】

Read MoreVertical Slurry Pump

high quality multistage slurry pump supplier...

high quality multistage slurry pump supplier 【high quality multistage slurry pump supplier】

Read MoreTo reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

high quality multistage slurry pump supplier...

high quality multistage slurry pump supplier 【high quality multistage slurry pump supplier】

Read MoreThere are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

high quality multistage slurry pump supplier...

high quality multistage slurry pump supplier 【high quality multistage slurry pump supplier】

Read MoreVertical Slurry Pumps Pump Sewage More Efficiently

high quality multistage slurry pump supplier...

high quality multistage slurry pump supplier 【high quality multistage slurry pump supplier】

Read MoreSlurry Pump

high quality multistage slurry pump supplier...

high quality multistage slurry pump supplier 【high quality multistage slurry pump supplier】

Read MoreMany types of pumps are used to pump slurry, but the most common slurry pump is the centrifugal pump. Centrifugal slurry pumps use centrifugal force from a rotating impeller to impinge kinetic energy on the slurry, similar to the way watery liquids pass through a standard centrifugal pump.

high quality multistage slurry pump supplier...

high quality multistage slurry pump supplier 【high quality multistage slurry pump supplier】

Read MoreSlurry Pump

high quality multistage slurry pump supplier...

high quality multistage slurry pump supplier 【high quality multistage slurry pump supplier】

Read MoreFirst, what is a slurry? A slurry is a semi-liquid mixture, usually consisting of fine particles. Examples of slurries can include manure, cement, starch, or coal suspended in water. There are countless other combinations that can be considered slurries. Because of the added particles and thicker consistency, special pump requirements should be considered. A standard pump may be able to handle the fluid, but not as effectively as a properly sized slurry pump.

high quality multistage slurry pump supplier...

high quality multistage slurry pump supplier 【high quality multistage slurry pump supplier】

Read More

Popular articles

- of a thick consistency, and.

- As this limestone slurry needs to be moved efficiently through a complex industrial process, the selection of the right pumps and valves (taking into account their whole life cycle costs and maintenance) is crucial.

- In a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

- What is a slurry?

- Slurry Pump Selection

- Find the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

Latest articles

-

If you have experience pumping slurries, you know it's not an easy task. Slurries are heavy and difficult to pump. They cause excessive wear on pumps and their components and are known to clog suction and discharge lines if not moving fast enough. Most importantly, it’s a challenge to make slurry pumps last for a reasonable amount of time. But, there are a few things you can do to extend the life of your slurry pump and make pumping slurry less of a challenge.

-

As this limestone slurry needs to be moved efficiently through a complex industrial process, the selection of the right pumps and valves (taking into account their whole life cycle costs and maintenance) is crucial.

-

When pumping slurry in wet sand applications, we must evaluate the abrasive particles flowing through the piping and then assess how they affect the slurry pump. If the pump is lined with poor quality rubber, the particles will not rebound effectively and, as a result, the rubber will begin to break down. The air shavings then begin to accelerate and negatively impact the efficiency of the pump, often leading to turbulence.

-

In a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

-

As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

-

Types of slurry pumps

Links

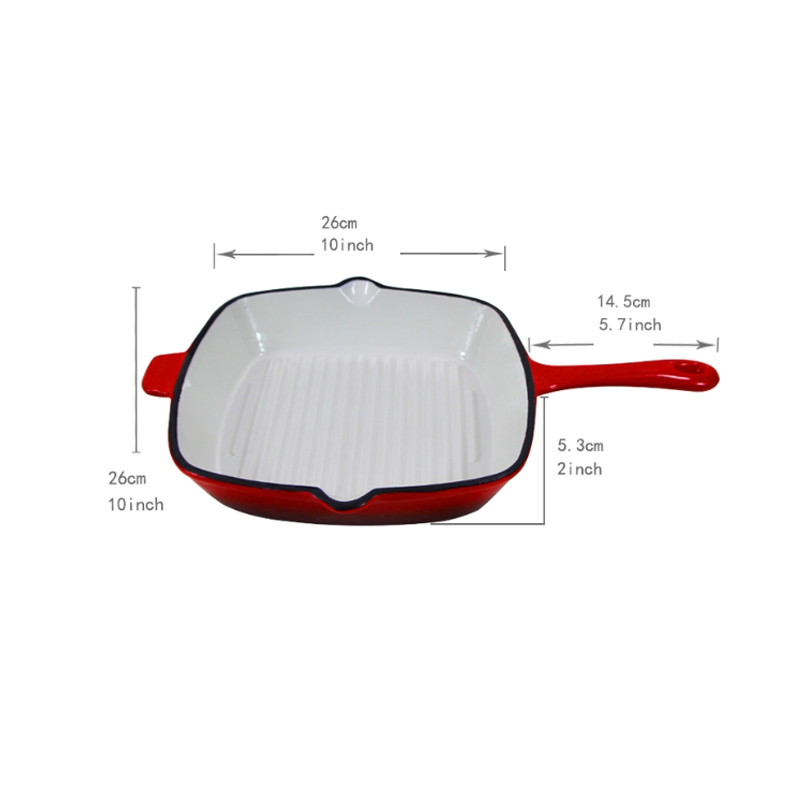

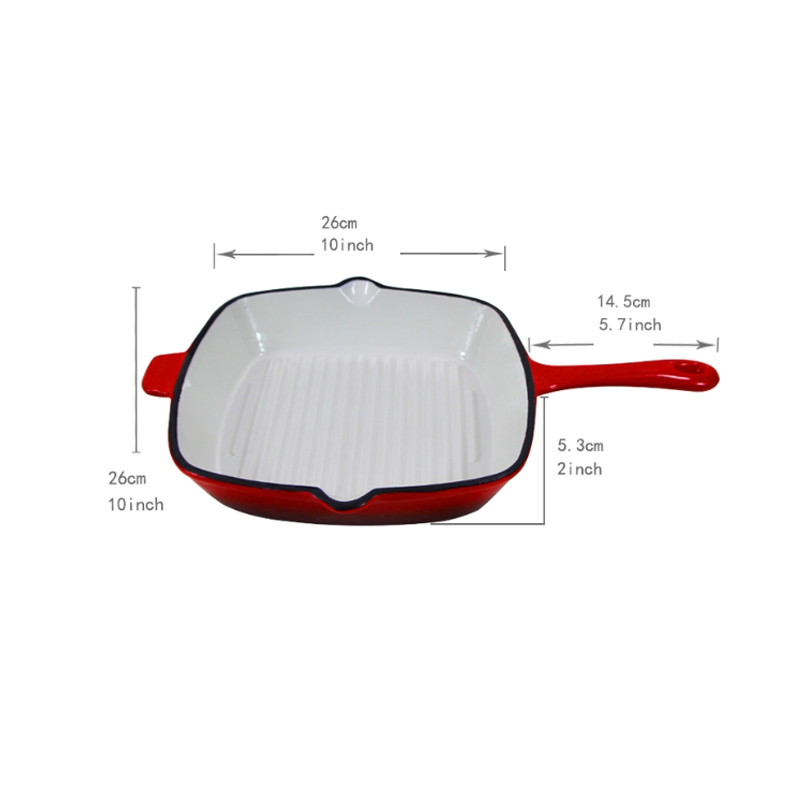

- In conclusion, an enamel coated cast iron grill pan is a valuable investment in any kitchen. It combines the time-tested qualities of cast iron with the convenience and beauty of enamel, offering a cooking experience that is both practical and pleasurable. Whether you're a seasoned chef or a beginner cook, this grill pan promises to elevate your culinary creations, bringing a touch of the outdoors into your indoor cooking. So, fire up your stove, let the grill marks sizzle, and savor the flavors that only an enamel coated cast iron grill pan can deliver.

While cast iron skillets take longer to heat up than other frying pan materials, they heat evenly and consistently with no hot spots. They are great at retaining heat and can be taken from the stovetop to the oven or grill and then to the table for service to keep the food warm. A well-seasoned cast-iron skillet is naturally non-stick and can withstand very high temperatures without warping or getting damaged. Cast iron requires frequent maintenance, but the benefit is that it can last a lifetime with routine seasoning and using proper cleaning techniques.

Rare - However, like any fine culinary instrument, proper care is crucial. Avoid using metal utensils to prevent scratching the enamel, and always handle with care to protect the coating. Regular cleaning and occasional re-seasoning (if the enamel chips) can ensure its longevity.

- The ribbed grill pan, with its distinctive grooved surface, is designed to mimic the effects of an outdoor grill. These ridges not only create the iconic grill marks that add visual appeal to any dish but also serve a practical purpose by allowing excess fats and oils to drain away from the food. This feature makes it an excellent choice for those looking to prepare healthier meals without sacrificing flavor or texture.

Stainless steel is also known as (rarely) casting iron - In conclusion, the meat press for sale represents more than just a piece of machinery; it symbolizes the intersection of tradition and innovation in the food industry. Whether you're a seasoned butcher or a new entrant, investing in a high-quality meat press can significantly enhance your operations, boost productivity, and ultimately, satisfy the demands of discerning consumers. As the market continues to evolve, so does the technology behind these indispensable tools, promising a future of efficient and safe meat processing.

- The use of a cast iron griddle on an electric stove also allows for a unique cooking experience. Because cast iron can endure high temperatures without damage, it permits chefs to start with a fierce heat for searing and locking in the flavors before reducing the stove's heat to finish cooking gradually. This method is particularly effective for foods that require a golden-brown exterior while preserving juiciness within.

- When it comes to outdoor cooking, there's nothing quite like the classic charm and versatility of a cast iron camp oven. These time-tested culinary tools have been a staple for campers, hikers, and outdoor enthusiasts for generations, offering a unique blend of durability, heat retention, and delicious food preparation capabilities.

Below is a table of the distinct features of a frying pan:

SKILLET AND FRYING PAN MATERIALS

What's a Saute Pan and How Does it Differ?

Like their aluminum counterpart, carbon steel frying pans are an excellent conductor of heat. However, they are a more durable and long-lasting option with the proper care, plus they can be used on induction cooktops. They can maintain both low and high temperatures for greater versatility and can cook both delicate foods like eggs and fish as well as sear thick meats like steaks and pork chops. Like cast iron, carbon steel pans require regular seasoning to maintain their non-stick capabilities. However, they heat up faster and are more lightweight, making them a great alternative to cast iron skillets. It is important to note that carbon steel pans are not ideal for cooking acidic foods as they can alter the foods' taste.

French skillets are perfect for cooking steaks and other meats that require high temperature and char.

Hard-anodized frying pans are made of aluminum which has been treated to make it hard and durable. They're also non-stick, but unlike the first two types of non-stick pans, they can take high temperatures without getting damaged. They're heavy and they don't get scratched when used with metallic utensils.

The Dutch oven is a versatile and essential piece of cookware that has been used for centuries. The Dutch oven is a heavy-duty pot with a tight-fitting lid designed for slow cooking, braising, and baking. Dutch ovens come in a variety of types and materials, each with its own unique uses and functions.

blue enamel cookware. Unlike some other cookware materials, it can be easily washed by hand or placed in a dishwasher, maintaining its pristine appearance with minimal effort. However, care should be taken to avoid harsh abrasives that could damage the enamel.

blue enamel cookware. Unlike some other cookware materials, it can be easily washed by hand or placed in a dishwasher, maintaining its pristine appearance with minimal effort. However, care should be taken to avoid harsh abrasives that could damage the enamel.

Enamel pots come in a variety of colors and designs, so you can choose one that complements your kitchen decor. Whether you prefer a classic white pan or a vibrant, colorful option, there's something to suit your taste.

ARE SKILLETS AND FRYING PANS THE SAME?

two sided griddle. The flat side of the griddle is perfect for cooking foods that need to be cooked evenly, such as pancakes or eggs. The ridged side, on the other hand, is great for grilling meats and creating those coveted grill marks. By being able to adjust the heat on each side independently, you can ensure that your food is cooked to perfection every time.

This not only makes cleaning a breeze but also enhances the flavor of your food by adding a depth of flavor that comes from years of seasoning This not only makes cleaning a breeze but also enhances the flavor of your food by adding a depth of flavor that comes from years of seasoning

This not only makes cleaning a breeze but also enhances the flavor of your food by adding a depth of flavor that comes from years of seasoning This not only makes cleaning a breeze but also enhances the flavor of your food by adding a depth of flavor that comes from years of seasoning cast iron flat top gas grill.

cast iron flat top gas grill.