slurry pump centrifugal factory

Latest articles

The slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

slurry pump centrifugal factory...

slurry pump centrifugal factory 【slurry pump centrifugal factory】

Read MoreSome models can generate discharge pressures up to 260 ft. (80 m).

slurry pump centrifugal factory...

slurry pump centrifugal factory 【slurry pump centrifugal factory】

Read MoreIn addition, a new level of complexity is added to an otherwise simple machine. Other parts must now be inventoried and training beyond basic spanner turning is required. When it comes to pumping rock and some of the world's most abrasive materials.

slurry pump centrifugal factory...

slurry pump centrifugal factory 【slurry pump centrifugal factory】

Read Moremethod and level of design reach international advanced level. The company has the first-class pump performance

slurry pump centrifugal factory...

slurry pump centrifugal factory 【slurry pump centrifugal factory】

Read MoreIf pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

slurry pump centrifugal factory...

slurry pump centrifugal factory 【slurry pump centrifugal factory】

Read MorePumps with replaceable parts and components can have an unlimited service life. A high quality customised slurry pump with replaceable parts can last you a lifetime and should therefore be considered as a very reliable long-term investment.

slurry pump centrifugal factory...

slurry pump centrifugal factory 【slurry pump centrifugal factory】

Read MoreWhat is a dredging pump?

slurry pump centrifugal factory...

slurry pump centrifugal factory 【slurry pump centrifugal factory】

Read MoreStep 2

slurry pump centrifugal factory...

slurry pump centrifugal factory 【slurry pump centrifugal factory】

Read MorePumping slurry can be a challenging problem, but with the right instruction, pumping and maintenance plan, you will achieve operational success.

slurry pump centrifugal factory...

slurry pump centrifugal factory 【slurry pump centrifugal factory】

Read MoreStep 4

slurry pump centrifugal factory...

slurry pump centrifugal factory 【slurry pump centrifugal factory】

Read More

Popular articles

- A slurry is any mixture of a fluid (such as water) and a powdery solid. Slurries are used as a convenient way to handle bulk solids in the mining, steel processing, foundry, power generation and, more recently, frac sand mining industries. Slurries typically behave like viscous viscous fluids, flowing under gravity, but can also be pumped as needed.

- Slurry Pump

- Damage to slurry pumps can range from burst seals to bearings and component housings wearing out where they join, to impellers corroding due to cavitation or severe wear and so on. However, there are solutions to these problems.

- How Slurry Pumps Differ From Standard Pumps?

- Submersible slurry pump pumps offer many advantages over dry and semi-dry (cantilever) mounted pumps.

- Mechanical Seals

Latest articles

-

The size and nature of the solids in the liquid: The size and nature will affect the amount of physical wear on the pump and its components, and whether the solids will pass through the pump without being damaged.

-

Slurry pump impeller, is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

-

-When pumping abrasive slurries, it is essential to use wear-resistant components with a high chromium content. But more is not always better - above 25%, the impeller becomes brittle.

-

Slurry Pump

-

Is the discharge configuration suitable for abrasive slurries?

-

WY type pump casing is made of abrasion resistant metal, impeller material can be abrasion resistant metal or rubber. The submerged parts of WYJ are all lined with rubber, for transfer corrosive slurry.

Positive Aspects:

So, only use bell pepper powder if the color won't affect the overall quality of your dish.

When it comes to drying paprika peppers, there are a few methods you can choose from based on your preference and equipment available. Each method has its advantages, but using a dehydrator is generally considered the best approach, providing efficient and consistent results.

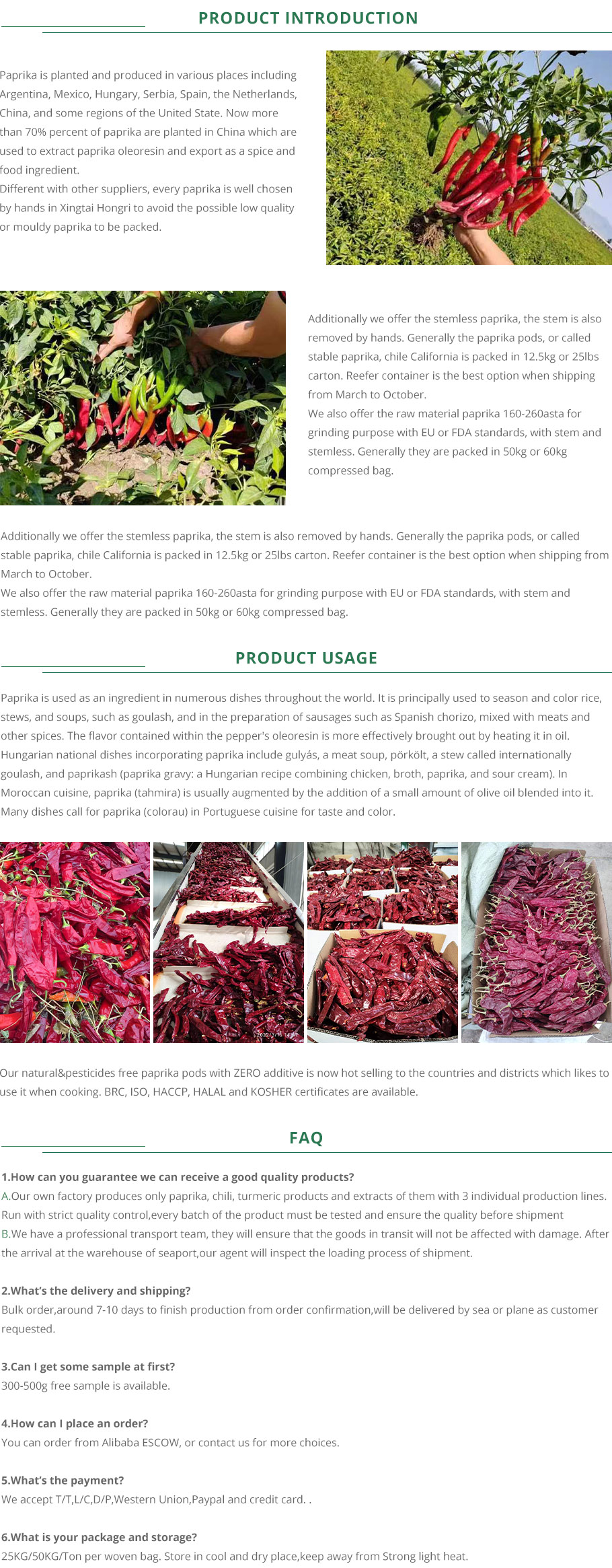

The word paprika is Hungarian for pepper. At its core, paprika is a powder made up of dried and finely ground red peppers. This globally popular spice can be sweet, spicy, or smoked. Not only does paprika add rich flavor, but also a beautiful red color to dishes.

They specialize in providing high-quality Sichuan peppercorns and other Sichuan-style seasonings They specialize in providing high-quality Sichuan peppercorns and other Sichuan-style seasonings

They specialize in providing high-quality Sichuan peppercorns and other Sichuan-style seasonings They specialize in providing high-quality Sichuan peppercorns and other Sichuan-style seasonings large dried chiles manufacturers. Their products are widely used in Chinese restaurants and homes across the country.

large dried chiles manufacturers. Their products are widely used in Chinese restaurants and homes across the country.You have a few options when it comes to spicy ketchup. You can easily make it yourself (see our recipe for smoky chipotle ketchup) or you can buy one of the many options available at most grocery stores. Heinz also carries a chili sauce in its line (affiliate link) that’s really much more like spicy ketchup than a Sriracha.

Where to Find Quality Spices

Dehydrator

In Mexico, pasilla and chipotle peppers form the backbone of smoky moles and table salsas In Mexico, pasilla and chipotle peppers form the backbone of smoky moles and table salsas

In Mexico, pasilla and chipotle peppers form the backbone of smoky moles and table salsas In Mexico, pasilla and chipotle peppers form the backbone of smoky moles and table salsas dried chili peppers. Further south, in the Andean regions of South America, the rocoto chili enlivens ceviches and marinades with its distinctive flavor profile. In Asia, the Sichuan pepper's numbing heat complements the bold flavors of Mapo Tofu, creating a harmonious dance of taste and sensation.

dried chili peppers. Further south, in the Andean regions of South America, the rocoto chili enlivens ceviches and marinades with its distinctive flavor profile. In Asia, the Sichuan pepper's numbing heat complements the bold flavors of Mapo Tofu, creating a harmonious dance of taste and sensation. Solvent extraction uses a food-grade solvent like hexane to dissolve the pigments and essential oils, while CO2 extraction utilizes pressurized CO2 to separate the oleoresin without the need for additional chemicals Solvent extraction uses a food-grade solvent like hexane to dissolve the pigments and essential oils, while CO2 extraction utilizes pressurized CO2 to separate the oleoresin without the need for additional chemicals

Solvent extraction uses a food-grade solvent like hexane to dissolve the pigments and essential oils, while CO2 extraction utilizes pressurized CO2 to separate the oleoresin without the need for additional chemicals Solvent extraction uses a food-grade solvent like hexane to dissolve the pigments and essential oils, while CO2 extraction utilizes pressurized CO2 to separate the oleoresin without the need for additional chemicals paprika oleoresin factory. Both methods yield high-quality oleoresin, but the latter is preferred due to its eco-friendliness and non-toxic nature.

paprika oleoresin factory. Both methods yield high-quality oleoresin, but the latter is preferred due to its eco-friendliness and non-toxic nature.Whisk the Ingredients. Add all of the ingredients to a large bowl. Whisk them together until the chili sauce is nicely uniform and all of the ingredients are mixed through. You can also use a blender or food processor, but a whisk is usually sufficient.

Paprika and chili products encompass a wide range of spices and seasonings derived from different types of peppers. These products are not only used for their distinctive flavors but also for their vibrant colors, which can enhance the visual appeal of dishes. Some popular paprika products include:

They meticulously source the finest peppers, adhere to strict quality control measures, and employ advanced grinding techniques to maintain the integrity of the spice They meticulously source the finest peppers, adhere to strict quality control measures, and employ advanced grinding techniques to maintain the integrity of the spice

They meticulously source the finest peppers, adhere to strict quality control measures, and employ advanced grinding techniques to maintain the integrity of the spice They meticulously source the finest peppers, adhere to strict quality control measures, and employ advanced grinding techniques to maintain the integrity of the spice wholesale paprika koral. In doing so, they guarantee that the end product retains the authentic flavor and aroma that defines paprika Koral.

wholesale paprika koral. In doing so, they guarantee that the end product retains the authentic flavor and aroma that defines paprika Koral.Overall, crushed red pepper factories play a vital role in the spice industry, providing consumers with a versatile and flavorful ingredient that can elevate a wide range of dishes. Their commitment to quality and innovation ensures that crushed red pepper remains a staple in kitchens around the world. So next time you reach for that bottle of crushed red pepper, remember the hard work and dedication that goes into producing this essential spice.

Grown in the Xinjiang Uygur Autonomous Region, this variety imparts a distinctive, almost peppery taste to dishes, making it perfect for lamb or beef recipes Grown in the Xinjiang Uygur Autonomous Region, this variety imparts a distinctive, almost peppery taste to dishes, making it perfect for lamb or beef recipes

Grown in the Xinjiang Uygur Autonomous Region, this variety imparts a distinctive, almost peppery taste to dishes, making it perfect for lamb or beef recipes Grown in the Xinjiang Uygur Autonomous Region, this variety imparts a distinctive, almost peppery taste to dishes, making it perfect for lamb or beef recipes china types of paprika powder. Its high carotenoid content also gives it an intense orange-red color.

china types of paprika powder. Its high carotenoid content also gives it an intense orange-red color.

curcumin extract from turmeric manufacturers.

Although red peppers originated in North America, they were brought to Europe in the 1500s, starting in Spain and Portugal, before making their way via the spice trade to North Africa, Central Europe, and even Asia. Today, paprika has established itself as a pantry staple from the Mediterranean to North Africa, Africa, and the Middle East.

They often specialize in specific types of pepper powder, like the famed Sichuan pepper, which offers a unique aroma and mild numbing sensation alongside its heat They often specialize in specific types of pepper powder, like the famed Sichuan pepper, which offers a unique aroma and mild numbing sensation alongside its heat

They often specialize in specific types of pepper powder, like the famed Sichuan pepper, which offers a unique aroma and mild numbing sensation alongside its heat They often specialize in specific types of pepper powder, like the famed Sichuan pepper, which offers a unique aroma and mild numbing sensation alongside its heat ground red pepper powder exporters.

ground red pepper powder exporters.WHAT IS PAPRIKA?

HOTTEST: THE END: FLATLINE HOT SAUCE

This step ensures that only the best peppers proceed to the grinding phase This step ensures that only the best peppers proceed to the grinding phase

This step ensures that only the best peppers proceed to the grinding phase This step ensures that only the best peppers proceed to the grinding phase chilito powder manufacturers. Using specialized equipment, manufacturers grind the dried peppers into a fine or coarse powder, depending on the desired texture for different recipes and applications.

chilito powder manufacturers. Using specialized equipment, manufacturers grind the dried peppers into a fine or coarse powder, depending on the desired texture for different recipes and applications.