seal for 5 inch dredge pump

Latest articles

Materials of Construction

seal for 5 inch dredge pump...

seal for 5 inch dredge pump 【seal for 5 inch dredge pump】

Read MoreStep 4

seal for 5 inch dredge pump...

seal for 5 inch dredge pump 【seal for 5 inch dredge pump】

Read MoreMaterials of Construction

seal for 5 inch dredge pump...

seal for 5 inch dredge pump 【seal for 5 inch dredge pump】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

seal for 5 inch dredge pump...

seal for 5 inch dredge pump 【seal for 5 inch dredge pump】

Read More>Slurry pump impeller is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

seal for 5 inch dredge pump...

seal for 5 inch dredge pump 【seal for 5 inch dredge pump】

Read MoreNon-settling slurries consist of very fine particles that do not settle to the bottom of the pipe and do not settle for very long (i.e. weeks).

seal for 5 inch dredge pump...

seal for 5 inch dredge pump 【seal for 5 inch dredge pump】

Read MoreWhen pumping slurry in wet sand applications, we must evaluate the abrasive particles flowing through the piping and then assess how they affect the slurry pump. If the pump is lined with poor quality rubber, the particles will not rebound effectively and, as a result, the rubber will begin to break down. The air shavings then begin to accelerate and negatively impact the efficiency of the pump, often leading to turbulence.

seal for 5 inch dredge pump...

seal for 5 inch dredge pump 【seal for 5 inch dredge pump】

Read MoreSlurry Pump

seal for 5 inch dredge pump...

seal for 5 inch dredge pump 【seal for 5 inch dredge pump】

Read MoreIf you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

seal for 5 inch dredge pump...

seal for 5 inch dredge pump 【seal for 5 inch dredge pump】

Read MoreSlurry Pump

seal for 5 inch dredge pump...

seal for 5 inch dredge pump 【seal for 5 inch dredge pump】

Read More

Popular articles

- The company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

- Determine the operating parameters of the pump.

- Slurry Pump VS Mud Pump

- If you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

- Slurry Pump

- Slurry Pump

Latest articles

-

Slurry Pump

-

Better safety

-

A slurry pump is a mechanical device used for the pressure-driven transfer of a fluid mixture (aka slurry). The fluid mixture consists largely of water as a liquid and solids as minerals, sand, gravel, human excrement, drilling mud or mostly crushed material.

-

The selection of a dredge or >slurry pump can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

-

What we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. , Slurry pumps, are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

-

- Easy installation - Submersible pumps are relatively easy to install since the motor and worm gear are a single unit.

Links

for windows and doors - An aluminium window frame section is a critical component in modern architectural design, offering a perfect blend of aesthetics and functionality. This material has gained immense popularity due to its numerous benefits, making it a preferred choice for residential and commercial structures alike.

- In addition to their functionality, aluminium sliding door rollers also add to the aesthetic appeal of your home or business. The sleek design and smooth operation of these rollers can enhance the overall look of your space and create a more modern and sophisticated atmosphere.

Features of aluminum profiles for doors and windows:

- In conclusion, while wrought iron is indeed prone to rusting, proper care and maintenance can significantly extend its lifespan and preserve its beauty. It is not a material that will rust instantly, but neglect can hasten the process. Therefore, understanding the nature of wrought iron and committing to its upkeep can ensure that this timeless material continues to grace our homes and public spaces with its elegance and durability. Remember, the will of wrought iron to resist rust is largely dependent on the will of its owner to maintain it well.

Additional cost of powder coat varies depending on thickness of bar and colour choice. Add character to your home and choose your very own colour to complement your interior finishes today!

Sample swatches are available.Shipment by sea; by road; by train; multi-transportation.

- In conclusion, fixing screen door wheels is a simple and straightforward process that can be completed in just a few steps. By following these instructions, you can restore your screen door to its proper functioning and enjoy the benefits of fresh air and improved security once again.

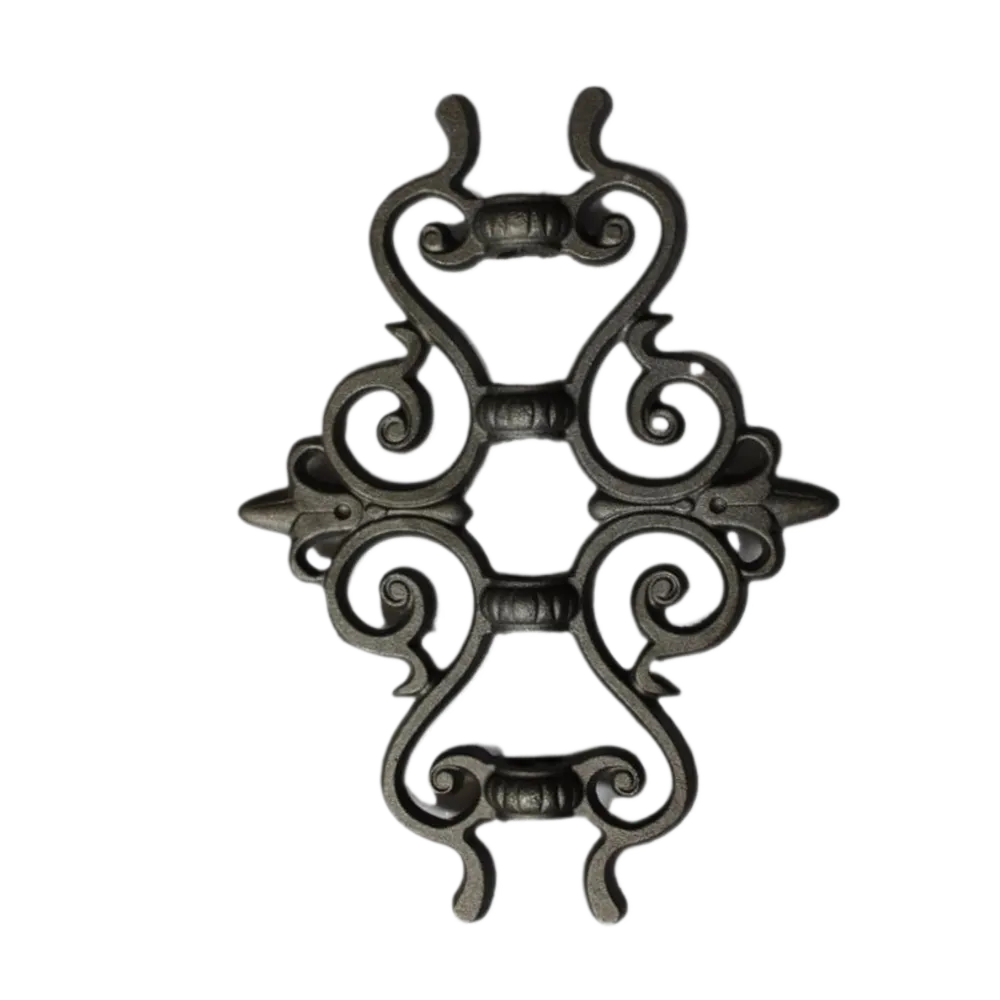

Investing in a wrought iron garden fence is not only a testament to your commitment to safety but also an enhancement of your property's aesthetics. Among the various fencing options available, a wrought iron fence stands out as the heavy-duty choice, characterized by its robust construction using durable metal tubing. This choice ensures longevity, promising a fence that can endure a lifetime with minimal maintenance requirements.

- One of the most important parts of a wrought iron fence is the posts. These vertical supports are typically set into the ground at regular intervals along the length of the fence and provide stability and structure. Posts can vary in design and size, depending on the style of the fence and the desired level of security. It is essential to ensure that the posts are securely anchored and properly aligned to prevent sagging or leaning over time.