high quality slurry pump supplier

Latest articles

There are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

high quality slurry pump supplier...

high quality slurry pump supplier 【high quality slurry pump supplier】

Read MoreTypes of damage to slurry pumps

high quality slurry pump supplier...

high quality slurry pump supplier 【high quality slurry pump supplier】

Read MoreThese conditions include

high quality slurry pump supplier...

high quality slurry pump supplier 【high quality slurry pump supplier】

Read MoreAier Machinery Hebei Co., Ltd. is a large-scale professional >slurry pumps manufacturer, gravel pumps, dredge pumps, sewage pumps and clean water pumps in China.

high quality slurry pump supplier...

high quality slurry pump supplier 【high quality slurry pump supplier】

Read MoreOne problem with centrifugal pumps is that the velocity and shear forces within the pump may damage the slurry/solids. Typically, twin-screw pumps cause the least damage to solids in the slurry.

high quality slurry pump supplier...

high quality slurry pump supplier 【high quality slurry pump supplier】

Read MoreSlurry Pump

high quality slurry pump supplier...

high quality slurry pump supplier 【high quality slurry pump supplier】

Read More>Slurry Pump

high quality slurry pump supplier...

high quality slurry pump supplier 【high quality slurry pump supplier】

Read MoreSlurry pump vs mud pump

high quality slurry pump supplier...

high quality slurry pump supplier 【high quality slurry pump supplier】

Read MoreSlurry Pump

high quality slurry pump supplier...

high quality slurry pump supplier 【high quality slurry pump supplier】

Read MoreSlurry Pump

high quality slurry pump supplier...

high quality slurry pump supplier 【high quality slurry pump supplier】

Read More

Popular articles

- Pump selection for FGD

- If the exact in-pump viscosity of the product is unknown, CSI can help

- Reduced inventory

- The frame plate for WAJ series pumps has interchangeable hard metal or pressure moulded elastomer liners. The impellers are made of pressure moulded elastomer liners.The shaft seals for WAJ series can be packing seal, centrifugal seal or mechanical seal.

- >Dredge Pump

- >Slurry Pump

Latest articles

-

Selecting a dredge pump

-

WA Heavy-duty Slurry Pump

-

Slurry Pump

-

Slurry pumps are usually larger than standard pumps, have more horsepower and use stronger bearings and shafts. The most common >type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids pass through a standard centrifugal pump.

-

Improved flow control

-

Slurry pump vs mud pump

The Double Needle Sewing Machine An Essential Tool for Modern Tailoring

1. Choose the Right Needle

Applications of Dual Needle Sewing Machines

While it might be tempting to opt for a less expensive model, it's essential to consider the long-term value of the investment. Cheaper machines may lack durability, advanced features, and may require frequent repairs, ultimately costing more in the long run. Investing in a mid-range or high-end auto sewing machine can provide years of reliable service and the capability to grow alongside your skills, making it a more economical choice over time.

Conclusion

The Importance of Hi-Speed Lockstitch in Modern Sewing Technology

Multi needle quilting machines are inherently versatile, providing quilters with the ability to explore a wide array of designs and techniques. With multiple needle systems, quilters can easily switch between different thread colors and types within a single project. This allows for complex designs, intricate motifs, and personalized embellishments that would typically be challenging to achieve by hand. Additionally, many multi needle machines come with built-in design software that offers a library of patterns, enabling users to choose and customize designs at their fingertips.

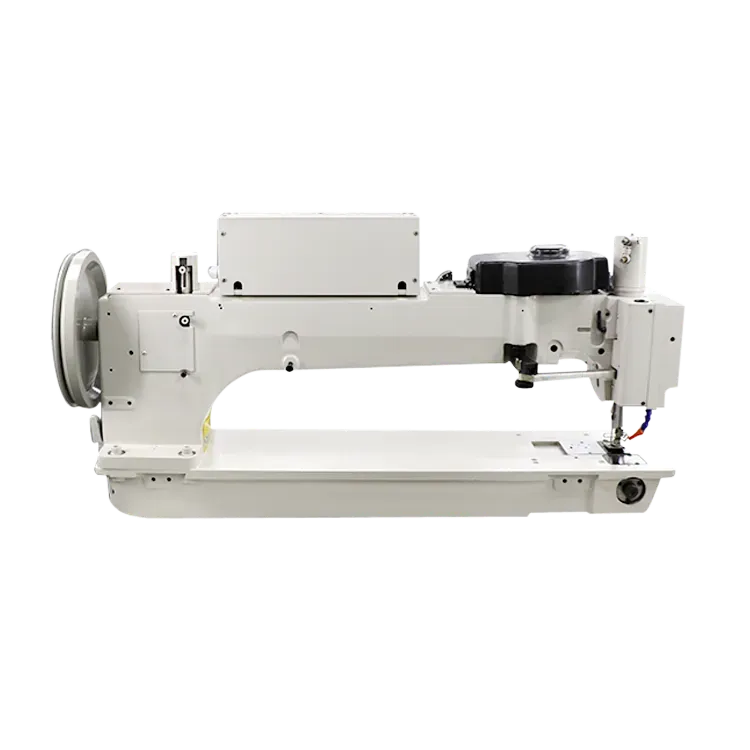

sail sewing machine with puller.

The features and functionalities of the cylinder bed sewing machine also play a critical role in determining its price. Machines equipped with specialized attachments, automated features, or advanced control systems may come at a premium. For instance, a machine with an automatic needle positioning feature, thread trimmer, or programmable sewing patterns can cost significantly more than a basic model with manual controls.

cylinder bed sewing machine price

Another crucial aspect of bulk bag sewing machines is the precision they offer. Consistent stitching is vital in ensuring the integrity and strength of the bags, especially when they are filled with heavy materials. High-quality sewing machines come equipped with advanced technology that enhances stitch quality and uniformity. This precision helps to prevent leaks and failures, which can have dire consequences in industries handling hazardous materials.

The Double Needle Lockstitch Machine A Versatile Tool in Textile Manufacturing

5. Large Throat Space Quilting often requires maneuvering large pieces of fabric, and a heavy-duty sewing machine typically offers a larger throat space. This design feature allows for easier handling of bulky quilts, enabling quilters to work on larger projects without feeling restricted.

When looking for a double needle walking foot sewing machine for sale, it's important to consider several factors to ensure you choose the right one for your needs. First, look for a model that boasts a strong motor and robust construction, as these features will enhance the machine's ability to tackle heavy fabrics. Additionally, features such as adjustable stitch length and width, a variety of presser feet, and easy threading mechanisms can greatly improve your sewing experience.

double needle walking foot sewing machine for sale

3. Easy Navigation The markings on the foot help sewers maintain consistency, especially when sewing intricate patterns or when sewing multiple layers of fabric.

Conclusion

A PP bag silai machine is specifically designed for sewing and stitching polypropylene bags, which are commonly used for packaging agricultural products, industrial materials, and consumer goods. These machines are engineered to handle various bag designs and sizes, making them an essential tool in factories that manufacture PP bags.

Exploring the Zig Zag Stitch Machine A Versatile Tool for Seamstresses

The advantages of using high-speed single needle lockstitch sewing machines are numerous. First and foremost is their ability to enhance production efficiency without compromising on quality. The uniform stitch quality helps in reducing fabric waste and minimizes the need for rework, which can be a significant cost saver for manufacturers.

Key Features

1. Multiple Thread Capability Most industrial sergers are designed to handle multiple threads, allowing for various stitch types. This variability is crucial for different fabrics and ends up reducing the likelihood of fraying or unraveling.

Additionally, the zigzag stitch is particularly beneficial when working with stretch fabrics, such as knits and spandex. It allows the fabric to maintain its elastic properties, which is essential for achieving a flattering fit in garments such as leggings and fitted tops.

In the world of sewing, the automatic buttonhole sewing machine stands out as an essential tool for both amateur and professional seamstresses. This device revolutionizes the way we create buttonholes, offering convenience, precision, and efficiency. With the growing popularity of DIY fashion and home sewing, understanding the benefits and uses of an automatic buttonhole sewing machine is crucial for anyone passionate about their craft.

Consistency is another critical advantage of auto sewing. Human error is an inherent risk in manual sewing processes, leading to variations in quality. However, with auto sewing technology, each stitch is uniform, reducing defects and waste. This consistency is crucial for brands that prioritize quality and reliability, as it enhances their reputation and customer satisfaction.

auto sewing

In summary, the industrial double needle sewing machine is a vital machinery in the garment industry, combining efficiency, versatility, and durability. As fashion trends evolve and consumer demands increase, the importance of reliable sewing technology will continue to grow. Manufacturers who invest in advanced double needle machines can enhance their productivity while ensuring that their products meet the highest standards of quality. With continual innovation in sewing technology, the industrial double needle sewing machine will undoubtedly remain a cornerstone of the textile manufacturing process for years to come.

5. Maintenance With simpler mechanics, single stitch leather sewing machines tend to require less maintenance than their more complicated counterparts. This ease of maintenance allows users to focus on their craft rather than troubleshooting mechanical issues.

Understanding Single Needle Lock Stitch A Key Technique in Sewing

Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020

1. Tote Bag

Understanding Bulk Bag Sewing Machines

Enhanced Creativity and Versatility