china slurry pump parts liner

Latest articles

Applications of Rubber Lined Slurry Pumps

china slurry pump parts liner...

china slurry pump parts liner 【china slurry pump parts liner】

Read MoreDredge Pump

china slurry pump parts liner...

china slurry pump parts liner 【china slurry pump parts liner】

Read MoreThere are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

china slurry pump parts liner...

china slurry pump parts liner 【china slurry pump parts liner】

Read MoreRubber lined pumps offer many advantages

china slurry pump parts liner...

china slurry pump parts liner 【china slurry pump parts liner】

Read MoreThe company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

china slurry pump parts liner...

china slurry pump parts liner 【china slurry pump parts liner】

Read MoreFlushing is defined as a fluid which is introduced into the seal cavity on the process fluid side, close to the seal face, and is normally used to cool and lubricate the seal face.

china slurry pump parts liner...

china slurry pump parts liner 【china slurry pump parts liner】

Read MoreTo find out more about Aier slurry Pumps, please >contact us.

china slurry pump parts liner...

china slurry pump parts liner 【china slurry pump parts liner】

Read More2. All have vertical pumps and horizontal pumps and can convey slurry.

china slurry pump parts liner...

china slurry pump parts liner 【china slurry pump parts liner】

Read MoreIn a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

china slurry pump parts liner...

china slurry pump parts liner 【china slurry pump parts liner】

Read MoreDredge Pump Features

china slurry pump parts liner...

china slurry pump parts liner 【china slurry pump parts liner】

Read More

Popular articles

- Dredge Pump Features

- >TL FGD Pump

- On the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

- A clear clean fluid supplied from an external source is normally used which is delivered to the main sealing surface on the fluid side of the sealing process. By using a closed gap throat bushing, the stuffing box can be back-pressurised to a higher pressure, ensuring that the flushing fluid does not flash across the seal face.

- Aier Machinery's team of consultants are on hand to provide you with a solution to your needs. Whether you are planning to purchase a slurry pump or need spare parts for an existing pump, we will help you determine your needs and provide advice on fine-tuning your equipment to your specific application.

- WA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

Latest articles

-

The slurry weight or consistency determines the type, design and capacity of the slurry pump required. If you have any questions about the best pump for your application, welcome to >contact us today or request a quote.

-

Slurry Pump

-

We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

-

With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

-

Caution: A common mistake is to over-pressurise the box and damage the expensive mechanical seal.

-

Natural rubber is an excellent wear material when handling wet sand slurries. Its strength, resilience and cut resistance have a positive impact on the wear performance of slurry pumps.

Links

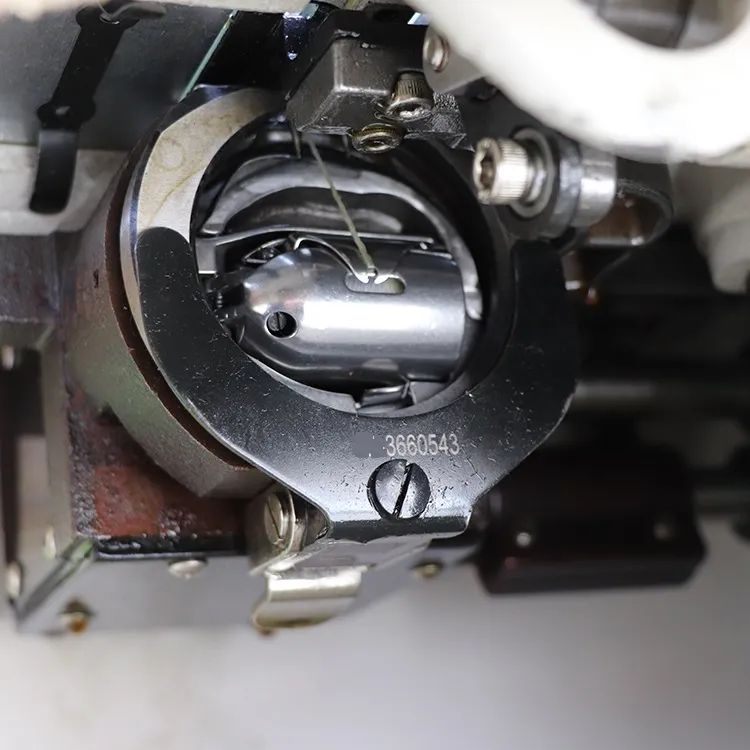

4. Speed Many lockstitch machines are designed for high-speed sewing, enabling manufacturers to boost productivity. Faster sewing speeds translate to increased output, which is vital in a competitive market.

- Ease of Use If you are new to upholstery, opt for a machine that is user-friendly with clear instructions. Additionally, look for models that offer good customer support and readily available parts.