warman centrifugal slurry pump manufacturers

Latest articles

Slurry Pump

warman centrifugal slurry pump manufacturers...

warman centrifugal slurry pump manufacturers 【warman centrifugal slurry pump manufacturers】

Read More2. All have vertical pumps and horizontal pumps and can convey slurry.

warman centrifugal slurry pump manufacturers...

warman centrifugal slurry pump manufacturers 【warman centrifugal slurry pump manufacturers】

Read More- Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

warman centrifugal slurry pump manufacturers...

warman centrifugal slurry pump manufacturers 【warman centrifugal slurry pump manufacturers】

Read MoreMagnetite mixing

warman centrifugal slurry pump manufacturers...

warman centrifugal slurry pump manufacturers 【warman centrifugal slurry pump manufacturers】

Read MorePumps with replaceable parts and components can have an unlimited service life. A high quality customised slurry pump with replaceable parts can last you a lifetime and should therefore be considered as a very reliable long-term investment.

warman centrifugal slurry pump manufacturers...

warman centrifugal slurry pump manufacturers 【warman centrifugal slurry pump manufacturers】

Read MoreLight-duty Slurry Pump

warman centrifugal slurry pump manufacturers...

warman centrifugal slurry pump manufacturers 【warman centrifugal slurry pump manufacturers】

Read MoreSlurry pumps can be used for.

warman centrifugal slurry pump manufacturers...

warman centrifugal slurry pump manufacturers 【warman centrifugal slurry pump manufacturers】

Read MoreThe winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

warman centrifugal slurry pump manufacturers...

warman centrifugal slurry pump manufacturers 【warman centrifugal slurry pump manufacturers】

Read More>Slurry pumps are typically larger than standard pumps, with more horsepower and stronger bearings and shafts. The most common type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids move through a standard centrifugal pump.

warman centrifugal slurry pump manufacturers...

warman centrifugal slurry pump manufacturers 【warman centrifugal slurry pump manufacturers】

Read More>Vertical Slurry Pump

warman centrifugal slurry pump manufacturers...

warman centrifugal slurry pump manufacturers 【warman centrifugal slurry pump manufacturers】

Read More

Popular articles

- A , slurry pump, is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

- Underwater installation

- The design of the slurry pump is critical to ensure that the abrasive and often corrosive aspects of the slurry do not damage the impeller. In addition, slurries and sludges may contain large amounts of unforeseen solids, which will inevitably clog many types of pumps. Since most centrifugal pump impellers have very tight tolerances on the worm gear, the abrasive (and sometimes corrosive) nature of the slurry will quickly wear down the worm gear and destroy the tolerances. In turn, this causes the pump to lose suction. This can lead to extensive downtime of the slurry pump, as well as expensive maintenance and spare parts.

- The size and nature of the solids in the liquid: The size and nature will affect the amount of physical wear on the pump and its components, and whether the solids will pass through the pump without being damaged.

- Again, to meet life cycle cost considerations, pumps should be equipped with large diameter impellers for lower operating speeds and longer wear life, as well as field replaceable rubber liners that can be bolted on for quick maintenance. In a typical coal-fired power plant, two to five pumps will be used in each spray tower.

- - Pumping the final product in a process

Latest articles

-

Fewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - usually 2-5 vanes.

-

3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

-

Slurry pump power adjustment

-

It is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

-

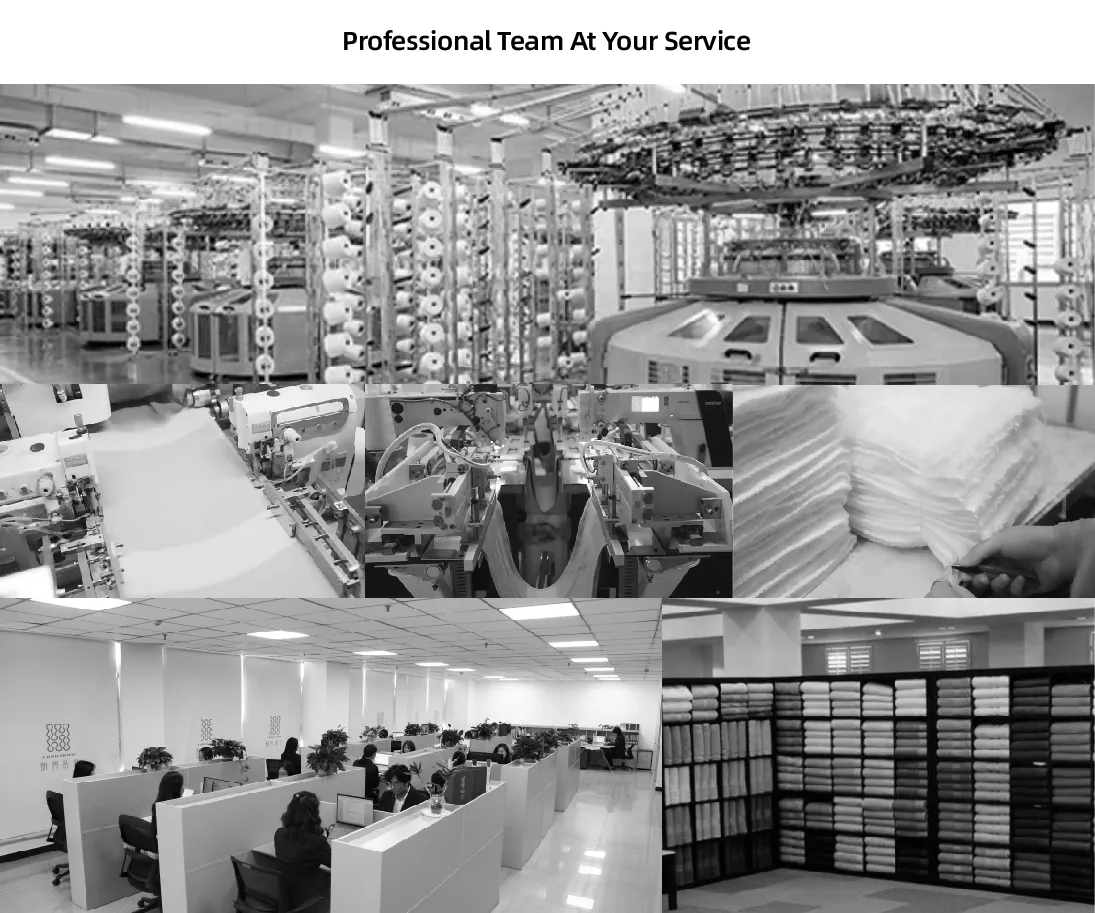

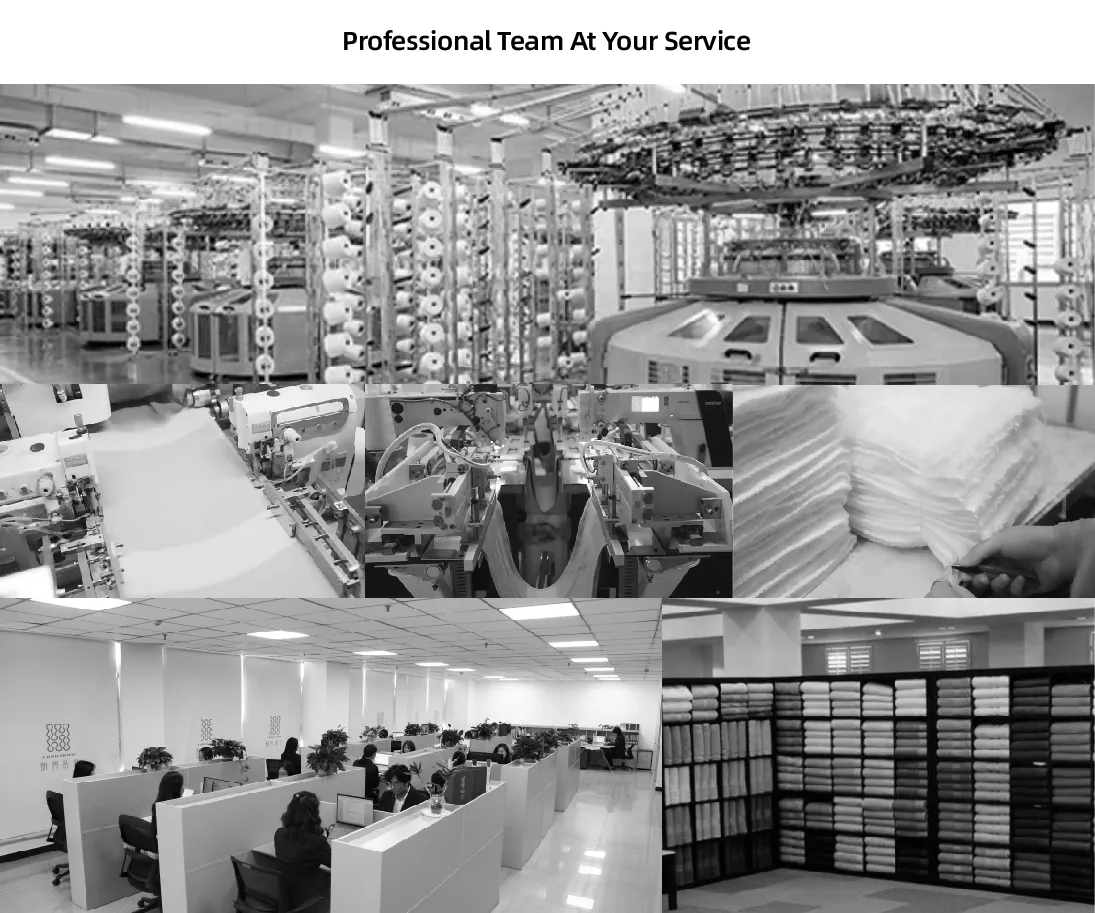

We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

-

- Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

While sateen sheets are similar to satin sheets, they aren’t to be confused with one another. The satin weave structure (one under, three over) creates sateen sheets, but yarn is used rather than filament fibers. Despite the differences in material, sateen sheets are just as elegant and silky smooth as satin. They are less durable than percale sheets but also better for cold sleepers and cooler weather.

Everything about the sort of cloth you pick for your bedding comes down to personal choice. Consider the fact that it is what your skin is resting on each night.

BAMBOO RAYON Bamboo Rayon sheets are made from a unique material of chemically treated bamboo. These sheets are unique because they can regulate temperature, making them perfect for any time of the year. This material also wicks away moisture while you sleep so you can always have a comfortable rest.

Linen is a very durable, lightweight fabric produced from the stem of the flax plant. Linen is a notoriously strong fiber. It’s three times stronger than cotton (the Bureau of Engraving and Printing even uses it to make bills) so you can expect your linen sheets to last for many years.

These sheets are normally flat and need to be tucked around the corners of the mattress to keep them in place during sleeping.

Most sheet sets typically include a flat sheet, fitted sheet, and one or two pillowcases. There’s not much need for wondering if you need a flat or fitted sheet for this reason — both are useful and usually come as a package deal. Some other sheet sets, like those Casper offers, also include a duvet cover.

You can use it as a standalone comforter or pair it with a lighter weight sheet set to create a cool and refreshing sleeping environment You can use it as a standalone comforter or pair it with a lighter weight sheet set to create a cool and refreshing sleeping environment

You can use it as a standalone comforter or pair it with a lighter weight sheet set to create a cool and refreshing sleeping environment You can use it as a standalone comforter or pair it with a lighter weight sheet set to create a cool and refreshing sleeping environment warm weather duvet insert. It's also easy to care for, as most warm weather duvet inserts are machine washable and dryer friendly.

warm weather duvet insert. It's also easy to care for, as most warm weather duvet inserts are machine washable and dryer friendly.

Hotel Towels Wholesale

percale cotton sheets. While higher thread counts often equate to increased softness, it's important to note that quality is equally dependent on the yarn's thickness and the weaving process. A well-made 250-thread-count percale sheet can often feel more comfortable and durable than a poorly constructed 500-thread-count sheet.

percale cotton sheets. While higher thread counts often equate to increased softness, it's important to note that quality is equally dependent on the yarn's thickness and the weaving process. A well-made 250-thread-count percale sheet can often feel more comfortable and durable than a poorly constructed 500-thread-count sheet. Silk bedding is also lightweight and breathable, providing a comfortable sleeping environment year-round Silk bedding is also lightweight and breathable, providing a comfortable sleeping environment year-round

Silk bedding is also lightweight and breathable, providing a comfortable sleeping environment year-round Silk bedding is also lightweight and breathable, providing a comfortable sleeping environment year-round bedding material types. However, silk can be delicate and requires careful handling and cleaning.

bedding material types. However, silk can be delicate and requires careful handling and cleaning. They also contribute to patient comfort, aiding in rest and recovery They also contribute to patient comfort, aiding in rest and recovery

They also contribute to patient comfort, aiding in rest and recovery They also contribute to patient comfort, aiding in rest and recovery hospital sheet sets.

hospital sheet sets.When it comes to hospital high-quality bedding, quality is crucial. High-quality bedding not only provides patient comfort but also helps create a clean, safe healthcare environment. Hospital bedding suppliers understand the unique requirements of healthcare facilities and offer a variety of products designed to meet these needs. From sheets and linens to pillows and blankets, these hospital bedding suppliers ensure hospitals have access to top-notch bedding to enhance patient comfort and support infection control measures.

The raised patterns provide a soothing massage effect, enhancing your post-shower relaxation The raised patterns provide a soothing massage effect, enhancing your post-shower relaxation

The raised patterns provide a soothing massage effect, enhancing your post-shower relaxation The raised patterns provide a soothing massage effect, enhancing your post-shower relaxation textured bath towels. They also have a superior grip, ensuring they don't slip off easily during use. The texture also helps to retain less water, thus reducing the time needed for drying and minimizing the risk of mold and mildew growth.

textured bath towels. They also have a superior grip, ensuring they don't slip off easily during use. The texture also helps to retain less water, thus reducing the time needed for drying and minimizing the risk of mold and mildew growth.Satin sheets, on the other hand, are made from a variety of materials, including silk, polyester, or nylon, and have a smooth, shiny finish.