hydraulic submersible slurry pump

Latest articles

Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read MoreAgain, to meet life cycle cost considerations, pumps should be equipped with large diameter impellers for lower operating speeds and longer wear life, as well as field replaceable rubber liners that can be bolted on for quick maintenance. In a typical coal-fired power plant, two to five pumps will be used in each spray tower.

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read MoreWhat is a dredging pump?

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read MoreSlurry Pump

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read MoreIn this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read MoreChoosing the right slurry pump

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read MoreAll manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read More>Slurry Pump VS Mud Pump

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read MoreTwo types of slurry are found in these industries.

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read MoreConveying medium

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read More

Popular articles

- Sites often rely on centrifugal pumps to provide slurry service. These pumps (and their associated piping systems) require special provisions that demand detailed knowledge of the properties of solids and slurries to prevent wear, corrosion, erosion and other adverse effects such as solids settling. Specifying the optimum combination of speed, geometry and material requires a proper balance of often conflicting pump priorities; this requires consideration of stable operation, maximum wear life, operational flexibility and minimum energy consumption.

- Series of TL >FGD pump is a single stage single suction horizontal centrifugal pump. It is mainly used as the circulation pump for absorbent tower in FGD applications. It has such features: wide range flowing capacity, high efficiency, high saving power. This series of pump is matched by tight structure X bracket which can save much space. Meanwhile our company develops many kinds of material targeted on the pumps for FGD.

- Slurry pumps can be used to transport mixtures of liquids and solids in many industries in a wide range of applications, such as mine drainage, dredging of sunken lagoons and pumping of drilling mud.

- Choosing the right pump for your slurry is critical to getting the most out of it. Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear caused by abrasive slurries. Compared to low-viscosity liquid pumps, target=_blank title=Slurry Pump>slurry pumps are typically larger and often require more horsepower to operate because they are less efficient. Bearings and shafts must also be more robust and durable.

- Applications of Rubber Lined Slurry Pumps

- Dredge Pump Features

Latest articles

-

Dredge Pump Features

-

The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

-

There are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

-

Slurry Pump

-

Slurry Pump

-

Slurry pump considerations

Links

Advantages of Using Lock Stitches

Automatic template sewing machines are designed to automate various sewing tasks, reducing the need for manual intervention. Unlike traditional sewing machines that require constant adjustments and oversight, these advanced machines use pre-programmed templates to execute intricate patterns and designs with precision. This automation allows for consistent quality across multiple pieces, which is particularly beneficial for mass production environments.

- The term single needle refers to the fact that this machine operates with one sewing needle, capable of creating straight stitches with unparalleled consistency. This singular focus allows for a cleaner, more preciseline, making it a popular choice for professionals and hobbyists alike who demand high-quality results.

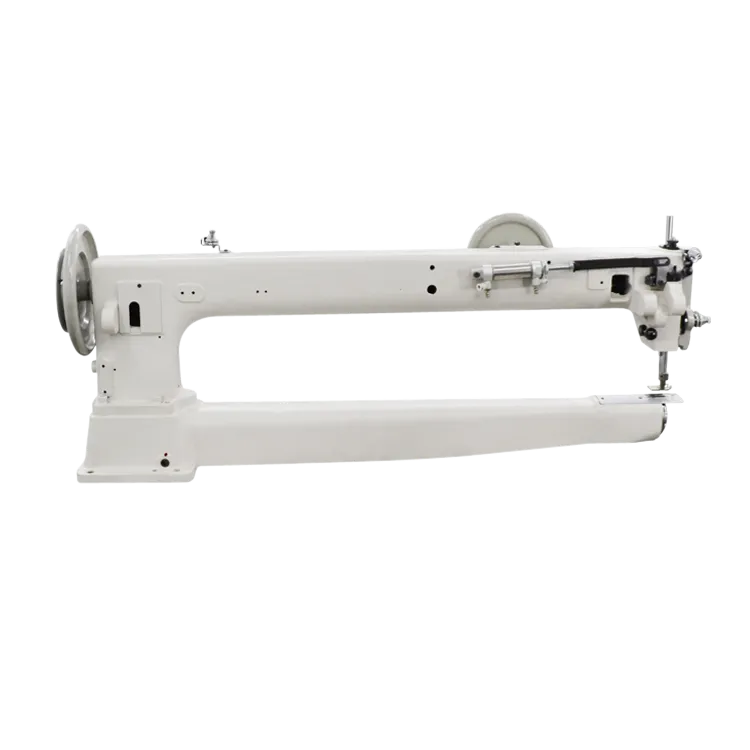

- Another advantage of heavy-duty post bed sewing machines is their versatility. They are capable of performing a wide range of sewing tasks, from basic stitches to intricate designs. This makes them suitable for various applications, from simple repairs to complex upholstery projects. With the right attachments and accessories, users can customize their machines to meet their specific sewing needs.

The Versatility and Advantages of Raised Bed Sewing Machines

The Versatility and Importance of Walking Foot Sewing Machines

- One of the main benefits of a double foot sewing machine is its ability to sew multiple layers of fabric at once. This is especially useful when working on projects that require thick or heavy materials, such as denim or leather. The dual feed system helps to prevent fabric from shifting or puckering as it passes under the needle, resulting in clean and professional-looking seams.

Many modern cylinder bed sewing machines come equipped with advanced features designed to improve usability and comfort. From automatic thread cutters to adjustable presser foot heights, these machines streamline the sewing process, allowing operators to focus on creativity rather than logistics. Additionally, the ergonomic design of the cylinder bed minimizes strain on the user, making it an excellent choice for long sewing sessions.

The Leather Manual Sewing Machine A Craftsperson’s Essential Tool

Moreover, the use of these machines allows for greater design flexibility. Fashion designers can experiment with different stitching techniques and fabric combinations, knowing that the right equipment is available to bring their visions to life. This creative freedom is essential in an industry that thrives on innovation and new trends.

Sewing machines are classified into different categories: electric, computerized, mechanical, overlock, and embroidery sewing machines. These machines have basic settings and ought to be used manually. Electronic sewing machines have motorized functions. The computerized machines can even be connected to the internet.

- A heavy-duty sewing machine is an essential tool for anyone who regularly works with heavy fabrics or multiple layers of fabric. Unlike regular sewing machines, heavy-duty machines are specifically designed to handle the demands of sewing through tough materials such as denim, leather, canvas, and various other thick fabrics.

Now people care more working efficiency, so extra big hook is coming in market. Now we highly improve the working speed for 6 time big hook to 1400rpm working speed, 10mm stitch length. So the working efficiency big hook have more advantage.

Furthermore, heavy-duty sewing machines are versatile. They can handle everything from basic home sewing tasks to more advanced projects such as making bags, curtains, upholstery, and quilts. Their ability to tackle various materials and thickness levels makes them a favorite among those who venture into crafts or clothing design.

- The single lockstitch machine has not just transformed the way clothes are made; it has shaped the global economy. It paved the way for mass production, reducing the cost of clothing and making it more accessible to the masses. It has also created job opportunities, especially in developing countries where the textile industry is a major contributor to the economy.

2. Walking Foot Mechanism One of the most important features to look for in an upholstery machine is a walking foot. This mechanism helps to evenly feed multiple layers of fabric through the machine, preventing shifting and ensuring that stitches are uniform. This is particularly valuable when working with thick or slippery materials.

When you are sewing, it is recommended to ensure you are working on a large surface. For example, when sewing large items such as beddings, upholstery, and curtains, you need a large surface. That is why you need to buy a heavy-duty sewing machine because it contains a large working area and throat size.

When you are sewing, it is recommended to ensure you are working on a large surface. For example, when sewing large items such as beddings, upholstery, and curtains, you need a large surface. That is why you need to buy a heavy-duty sewing machine because it contains a large working area and throat size. Before you purchase a sewing machine, you have to consider what you will be using it for and how often you use it. Usually, heavy duty sewing machines are used in industries because of their dependability and durability. These machines are equipped to handle tough tasks. The type of machine is quite excellent as far as dealing with heavy fabrics such as animal skin, denim, and leather. You will find it great for making blinds, buttonholes, quilts, and upholstery. These are some factors to consider before buying.

Before you purchase a sewing machine, you have to consider what you will be using it for and how often you use it. Usually, heavy duty sewing machines are used in industries because of their dependability and durability. These machines are equipped to handle tough tasks. The type of machine is quite excellent as far as dealing with heavy fabrics such as animal skin, denim, and leather. You will find it great for making blinds, buttonholes, quilts, and upholstery. These are some factors to consider before buying.