high quality slurry pump metal parts factory

Latest articles

Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

high quality slurry pump metal parts factory...

high quality slurry pump metal parts factory 【high quality slurry pump metal parts factory】

Read More600WN to 1000WN dredge pumps are of double casings, single stage cantilevered centrifugal pumps. These pumps are equipped with frame and lubrication is force thin oil. The design of double casing the pump working till the volute liner almost worn down and guarantee no leakage when volute liner is worn down.

high quality slurry pump metal parts factory...

high quality slurry pump metal parts factory 【high quality slurry pump metal parts factory】

Read MoreIf you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

high quality slurry pump metal parts factory...

high quality slurry pump metal parts factory 【high quality slurry pump metal parts factory】

Read MoreSlurry Pump Selection

high quality slurry pump metal parts factory...

high quality slurry pump metal parts factory 【high quality slurry pump metal parts factory】

Read MoreTo reduce wear, reduce the pump discharge pressure to the lowest possible point.

high quality slurry pump metal parts factory...

high quality slurry pump metal parts factory 【high quality slurry pump metal parts factory】

Read MoreThe size and nature of the solids in the liquid: The size and nature will affect the amount of physical wear on the pump and its components, and whether the solids will pass through the pump without being damaged.

high quality slurry pump metal parts factory...

high quality slurry pump metal parts factory 【high quality slurry pump metal parts factory】

Read MoreThe discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. There are many drive modes for option, such as V-belt, flexible coupling, gearbox, hydraulic coupler variable frequency, silicon controlled speed, etc. Among them, the flexible shaft coupling drive and V-belt feature of low cost and easy installation.

high quality slurry pump metal parts factory...

high quality slurry pump metal parts factory 【high quality slurry pump metal parts factory】

Read MoreBetter safety

high quality slurry pump metal parts factory...

high quality slurry pump metal parts factory 【high quality slurry pump metal parts factory】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

high quality slurry pump metal parts factory...

high quality slurry pump metal parts factory 【high quality slurry pump metal parts factory】

Read MoreDefinition of dredge and slurry pumps

high quality slurry pump metal parts factory...

high quality slurry pump metal parts factory 【high quality slurry pump metal parts factory】

Read More

Popular articles

- A >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

- Will solids size pass through the pump?

- - Pumping media where abrasive particles are present

- Keep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

- It is important that the pump you choose has components that will not wear out from abrasive slurries.

- A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right , pump, .xa0, In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

Latest articles

-

WY type pump casing is made of abrasion resistant metal, impeller material can be abrasion resistant metal or rubber. The submerged parts of WYJ are all lined with rubber, for transfer corrosive slurry.

-

The company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

-

Slurry Pump

-

2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

-

The slurry pump is mainly used in the mining industry, its wear resistance is strong. So It conveys slurry that containing slag, but it can conveys mud. The mud pump is usually made of cast iron, the wear resistance of the pump is low. So the mud pumps often used for conveying mud or slurry containing suspended particles.

-

Slurry Pump

Links

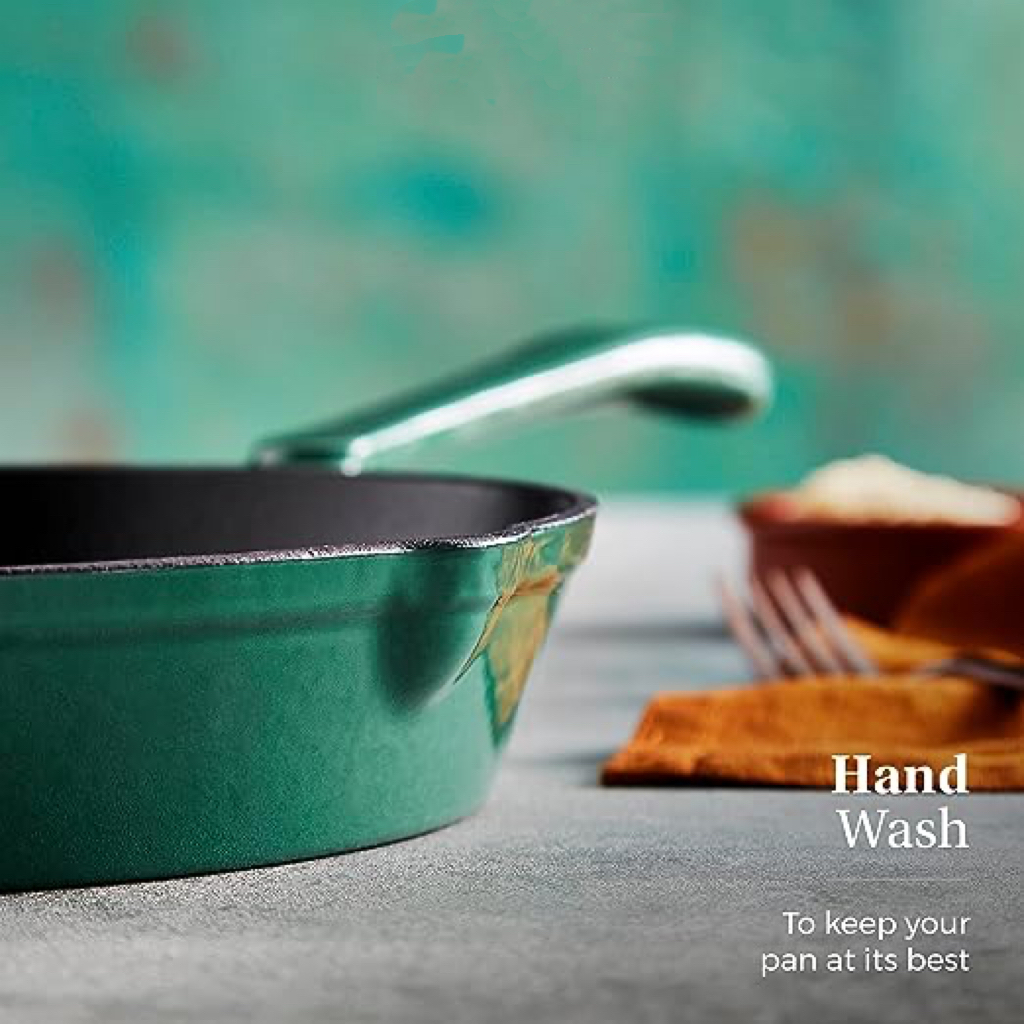

- One of the standout features of this pan is its distinctive grill design. The raised ridges create an authentic grilled flavor and texture, mimicking outdoor cooking in the comfort of your kitchen. The deep grooves effectively drain excess fat, promoting healthier cooking while adding a smoky, chargrilled touch to your meals.

- The beauty of cast iron lies in its ability to retain heat, ensuring those perfect grill marks you crave

- On the surface of the pot, one might find intricate designs or patterns etched gently into the enamel

Hearty and Flavorful Meals: Dutch ovens are perfect for creating hearty and flavorful meals such as stews, soups, roasts, and casseroles. Their ability to maintain a consistent temperature and seal in moisture results in tender and succulent dishes.

- Overall, the black enamel stock pot is a must-have for any home cook. With its durability, even heat distribution, and stylish design, this cookware piece is sure to become a staple in your kitchen. Whether you're a seasoned chef or just starting out, the black enamel stock pot is a reliable and versatile tool that will help you create delicious meals for years to come.

You can use it on the stovetop, in the oven, or even over a campfire You can use it on the stovetop, in the oven, or even over a campfire

You can use it on the stovetop, in the oven, or even over a campfire You can use it on the stovetop, in the oven, or even over a campfire